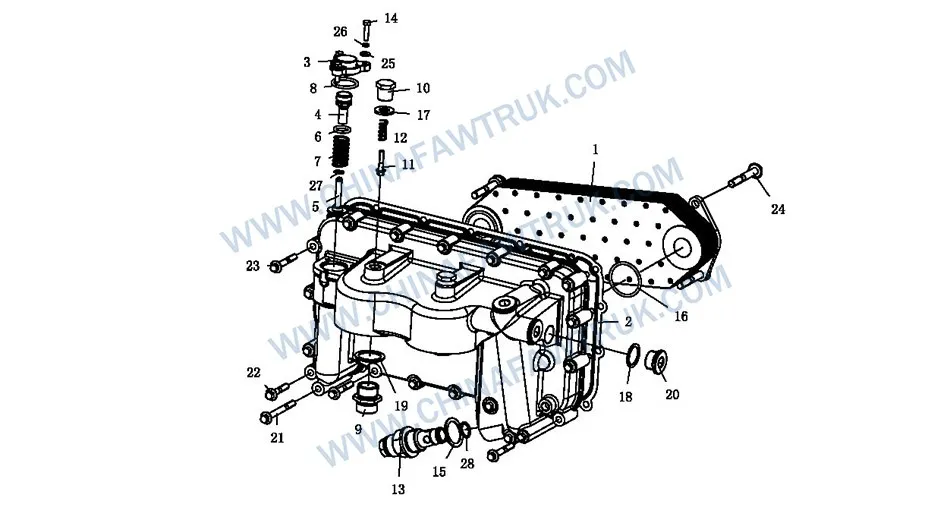

Resfriador de óleo de motor russo FAW: 28 Componentes vitais para regulação térmica suprema

O Resfriador de óleo de motor russo FAW is the thermal equilibrium device for the CA3250P66K24L1TE5Z heavy-duty engine. It manages the delicate balance between rapid warm-up in Arctic conditions and efficient heat rejection under heavy loads. This guide dissects the complex valve logic, pressure regulation, and sealing architecture that define this essential system.

Resfriador de óleo de motor russo FAW

Heat Exchange Architecture: The Core Assembly

The foundation of the thermal management system is the Conjunto do resfriador de óleo (Parte não. 1013010-81D). Dentro do Resfriador de óleo de motor russo FAW arquitetura, this component utilizes a stacked-plate or shell-and-tube design to maximize the surface area available for heat transfer. As hot oil circulates through the core, it sheds thermal energy into the engine coolant, which is then managed by the radiator.

In the extreme cold of the Russian Federation, the material composition of the housing is critical. It must withstand the thermal shock of hot oil entering a sub-zero aluminum casting without cracking. O Resfriador de óleo de motor russo FAW is engineered with reinforced ribbing to handle these internal stresses, ensuring structural integrity during the rapid heating cycles of a morning startup.

Sealing this unit to the engine block requires the Oil Cooler Body Gasket (Parte não. 1013012-81D). This is not a standard paper gasket; it is a high-performance composite designed to resist oil saturation and thermal degradation. If this gasket fails, high-pressure oil can leak externally or, pior, cross-contaminate with the coolant system, leading to the dreaded “milk-shake” in the sump.

O Resfriador de óleo de motor russo FAW system places a heavy reliance on the sealing quality of the Vedação do anel de o (Parte não. GB3452.1_46.2X3.55). Located at critical fluid junctions, these O-rings prevent fluid migration. Nas condições do Ártico, inferior rubber seals become brittle and fail; FAW uses fluoro-elastomers that remain pliable at -40°C to maintain a hermetic seal.

Cold Start Protection: The Bypass Mechanism

Uma característica definidora do Resfriador de óleo de motor russo FAW is its sophisticated bypass system. When the engine oil is cold and thick, forcing it through the fine passages of the cooler core creates dangerous backpressure. O Válvula – Válvula de desvio do resfriador de óleo (Parte não. 1013033-53D) is the safety mechanism that prevents the cooler from bursting under this pressure.

This valve is seated against the Valve Seat – Válvula de desvio do resfriador de óleo (Parte não. 1013032-53D). When the pressure differential exceeds a calibrated limit, o Primavera – Válvula de desvio do resfriador de óleo (Parte não. 1013036A53D) compresses, allowing the cold oil to bypass the cooler entirely. This ensures that the engine bearings receive immediate lubrication, even if the oil is too viscous to pass through the heat exchanger.

The entire bypass assembly is contained by the Tampa da válvula – Válvula de desvio do resfriador de óleo (Parte não. 1013031-53D), sealed with a dedicated Anel-O – Tampa da válvula (Parte não. 1013037-53D). No Resfriador de óleo de motor russo FAW, maintaining the integrity of this bypass circuit is vital. If the valve sticks open, the oil never cools; if it sticks closed, the cooler core may rupture during a cold snap.

Adicionalmente, the system includes a secondary protection layer involving the Bypass Valve (Parte não. 1013052-53D) e seu correspondente Valve Seat (Parte não. 1013051-53D). This redundancy in the Resfriador de óleo de motor russo FAW design underscores the focus on reliability. FAW engineers recognize that in remote Russian logistics routes, a single point of failure cannot be allowed to disable the vehicle.

System Stability: Pressure Regulation Assembly

Maintaining consistent oil pressure is the primary function of the Pressure Regulating Valve Assembly (Parte não. 1013060-81D). Situated within the cooler housing, this component acts as the master controller for system pressure. No Resfriador de óleo de motor russo FAW, this valve bleeds off excess pressure generated by the oil pump at high RPMs, returning it to the sump.

The precision of this valve determines the health of the engine. If the pressure is too low, bearings will touch metal-to-metal; if too high, seals will blow out. O Resfriador de óleo de motor russo FAW uses a precision-ground piston and spring within this assembly to ensure a linear response to engine speed changes, preventing pressure spikes that could damage the cooler core.

Connections to the full-flow filter are managed by the Parafuso de conexão – Full Flow Oil Filter (Parte não. 1013041-53D). These robust fasteners serve a dual purpose: securing the filter housing and providing a fluid passage. The metallurgy of these bolts in the Resfriador de óleo de motor russo FAW is toughened to resist the shear loads applied during filter removal and installation.

To seal the various ports and test points, a montagem utiliza o Hexagon Socket Plug (Parte não. Q/WC3410_M27X1.5). These plugs are essential for diagnostic access. Mechanics can remove them to attach mechanical pressure gauges, allowing for verification of the Resfriador de óleo de motor russo FAW performance without disassembling the engine.

The Clamping Strategy: Parafusos e arruelas

A integridade estrutural do Resfriador de óleo de motor russo FAW relies on a specific family of fasteners. The primary clamping load is provided by 16 unidades do Parafuso de flange hexadecimal (Tipo R) (Parte não. Q1820855), supported by smaller quantities of varying lengths like Part No. Q18208100 and Q1821070. O “Tipo R” designation indicates a reduced shank or specific elasticity designed to maintain tension during thermal expansion.

O design da cabeça do flange elimina a necessidade de arruelas separadas, providing a stable platform that resists vibration loosening. Isto é crucial para o Resfriador de óleo de motor russo FAW, which is bolted directly to the vibrating engine block. A loose bolt here would result in an immediate and massive oil leak.

Sealing the banjo connections and plugs requires a variety of copper washers, incluindo o Lavadora de cobre (Parte não. Q/WC3403_27X35) and smaller sizes like Q/WC3403_20X28. No Resfriador de óleo de motor russo FAW sistema, copper is the material of choice because it work-hardens upon compression, forming a permanent seal that is immune to the freeze-thaw cycles of the Russian climate.

Smaller fasteners, como o Parafuso de cabeça hexagonal (Parte não. CQ1500625), secure the cover plates and valve housings. Combined with the Arruela elástica (Parte não. Q40306) e Máquina de lavar (Parte não. Q40106), these ensure that even the lightest components remain secure. Every bolt in the Resfriador de óleo de motor russo FAW is a critical component in the fight against oil loss.

Lista detalhada de componentes

The following table details the comprehensive 28-part breakdown for the Resfriador de óleo de motor russo FAW. Using the exact part numbers is mandatory to ensure the pressure ratings and thermal properties match the OEM specification for the CA3250P66K24L1TE5Z.

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 |

1013010-81D |

Conjunto do resfriador de óleo |

1 |

| 2 |

1013012-81D |

Oil Cooler Body Gasket |

1 |

| 3 |

1013031-53D |

Tampa da válvula – Válvula de desvio do resfriador de óleo |

1 |

| 4 |

1013032-53D |

Valve Seat – Válvula de desvio do resfriador de óleo |

1 |

| 5 |

1013033-53D |

Válvula – Válvula de desvio do resfriador de óleo |

1 |

| 6 |

1013034-53D |

Anel-O – Válvula de desvio do resfriador de óleo |

1 |

| 7 |

1013036A53D |

Primavera – Válvula de desvio do resfriador de óleo |

1 |

| 8 |

1013037-53D |

Anel-O – Tampa da válvula |

1 |

| 9 |

1013041-53D |

Parafuso de conexão – Full Flow Oil Filter |

2 |

| 10 |

1013051-53D |

Valve Seat |

2 |

| 11 |

1013052-53D |

Bypass Valve |

2 |

| 12 |

1013053A53D |

Primavera |

2 |

| 13 |

1013060-81D |

Pressure Regulating Valve Assembly |

1 |

| 14 |

CQ1500625 |

Parafuso de cabeça hexagonal |

3 |

| 15 |

CQ72322 |

Arruela de vedação |

1 |

| 16 |

GB3452.1_46.2X3.55 |

Vedação do anel de o |

2 |

| 17 |

Q/WC3403_20X28 |

Lavadora de cobre |

2 |

| 18 |

Q/WC3403_27X35 |

Lavadora de cobre |

3 |

| 19 |

Q/WC3403_30X40 |

Lavadora de cobre |

2 |

| 20 |

Q/WC3410_M27X1.5 |

Hexagon Socket Plug |

3 |

| 21 |

Q18208100 |

Parafuso de flange hexadecimal (Tipo R) |

3 |

| 22 |

Q1820845 |

Parafuso de flange hexadecimal (Tipo R) |

1 |

| 23 |

Q1820855 |

Parafuso de flange hexadecimal (Tipo R) |

16 |

| 24 |

Q1821070 |

Parafuso de flange hexadecimal (Tipo R) |

4 |

| 25 |

Q40106 |

Máquina de lavar |

3 |

| 26 |

Q40306 |

Arruela elástica |

3 |

| 27 |

Q43108 |

Anel de retenção elástico do eixo |

1 |

| 28 |

Q7342422A |

Vedação de borracha com anel de vedação |

1 |

Diagnostic Protocols for Thermal Health

Inspecionando o Resfriador de óleo de motor russo FAW requer vigilância. Look for signs of external leakage around the Oil Cooler Body Gasket. Oil stains here can indicate loose bolts or a degraded gasket. Never attempt to stop a leak by over-tightening the bolts, as this can warp the aluminum housing. Em vez de, replace the gasket and torque to spec.

Internal leaks are more insidious. Check the engine coolant for an oily sheen, which indicates oil pressure is forcing lubricant into the water jacket past a failed Vedação do anel de o. Por outro lado, check the dipstick for “mayonnaise” sludge, a sign that coolant has breached the cooler core and entered the oil sump.

Finalmente, verify the operation of the Bypass Valve. If the engine takes an unusually long time to reach operating oil temperature, the valve may be stuck open. If the oil filter canister bulges or bursts on a cold start, the valve is likely stuck closed. Regular oil analysis can detect the wear metals associated with these thermal failures before they destroy the engine.

Conclusão: The Thermostat of Lubrication

O Resfriador de óleo de motor russo FAW is a sophisticated thermal management system that does far more than just cool oil. It regulates pressure, ensures cold-start safety, and protects the engine from thermal shock. Cada componente, do Pressure Regulating Valve Assembly to the specific copper washers, plays a vital role in this ecosystem.

For fleet owners operating in the unforgiving Russian climate, maintaining this assembly with genuine FAW parts is non-negotiable. Generic coolers often lack the internal reinforcement and precise valve calibration required to survive -40°C starts. Ao investir no autêntico Resfriador de óleo de motor russo FAW, you ensure that your fleet remains reliable, eficiente, and profitable, regardless of the weather.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.