FAW Russian Sub-Box Housing Assembly: Engineering 17 Strategic Components for Unyielding Transmission Performance

The FAW Russian Sub-Box Housing Assembly serves as the structural command center for the range-splitting capabilities of the CA3250P66K24L1TE5Z dump truck. This robust rear casing encapsulates the auxiliary gear train, the power take-off (PTO) interface, and the critical output shaft bearings. Engineered to withstand the torsional twisting of Siberian mining operations, this assembly ensures seamless high-low range transitions.

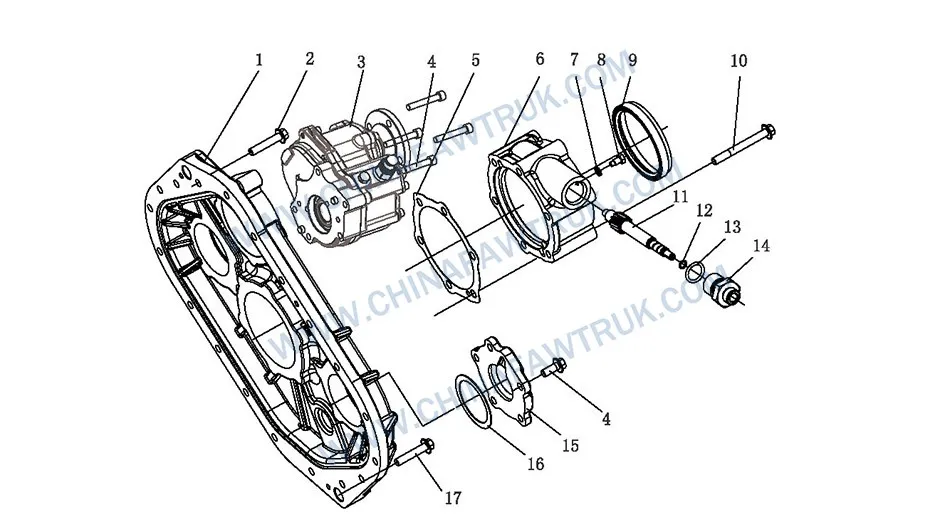

FAW Russian Sub-Box Housing Assembly

Housing Architecture: The Sub-Box Shell

The foundation of this system is the Sub-box Housing (Part No. 1701501FA0L). In the context of the FAW Russian Sub-Box Housing Assembly, this component is not merely a cover; it is a structural chassis that must bear the reaction loads of the planetary reduction gears. Manufactured from high-strength grey iron or nodular graphite iron, the housing is designed to maintain dimensional stability across a temperature range of 140°C. In the Russian Arctic, where ambient temperatures drop to -40°C, the metallurgy of the FAW Russian Sub-Box Housing Assembly prevents cold-brittleness stress fractures that plague lesser materials.

The housing features intricate internal webbing to support the rear bearings of the main shaft and countershafts. This internal ribbing dissipates the heat generated by the churning gear oil, acting as a passive heat sink. For the FAW Russian Sub-Box Housing Assembly, maintaining oil viscosity is critical. If the housing allows the oil to overheat, the lubricating film breaks down; if it cools too rapidly, the oil thickens to sludge. The mass and surface area of the housing are calculated to modulate this thermal inertia, ensuring optimal lubrication dynamics for the gears housed within.

Securing this massive casting to the main transmission case requires robust hardware. The assembly utilizes 16 units of the Hexagon Flange Bolt Coarse Shank (Standard) (Part No. Q1841035S). The choice of flange bolts for the FAW Russian Sub-Box Housing Assembly is deliberate. The integrated flange distributes the high clamping load over a wider area of the casting flange, preventing cracking. The coarse thread pitch provides superior grip in the cast iron of the main case, resisting the tendency to loosen under the heavy vibration inherent in diesel dump truck operations.

Power Take-Off: The Hydraulic Heart

For a dump truck, the transmission must do more than drive the wheels; it must power the hydraulic lift system. The FAW Russian Sub-Box Housing Assembly integrates the PTO Assembly (Part No. 4207010-YQA7GN1) directly into its rear architecture. This direct-mount configuration eliminates the need for intermediate driveshafts, reducing complexity and potential failure points. The PTO draws power from the transmission countershaft, converting rotational energy into hydraulic pressure to lift the multi-ton dump bed.

The mounting interface for the PTO is critical. It is secured by Hexagon Flange Bolt Coarse Shank (Standard) (Part No. Q1841025S). The sealing at this interface must be perfect; a leak here would drain the transmission of fluid, leading to catastrophic failure. The FAW Russian Sub-Box Housing Assembly ensures precise machining of the PTO mounting face to guarantee a leak-free seal. The rigidity of the sub-box housing prevents the PTO unit from flexing under load, which would otherwise cause gear misalignment and rapid tooth wear.

In the harsh conditions of a Russian mine, the PTO is often engaged while the transmission fluid is still cold and viscous. The robust design of the FAW Russian Sub-Box Housing Assembly provides the necessary support for the PTO gears to cut through this thick oil without deflecting. This ensures reliable engagement of the dump mechanism even in the deepest winter, preventing downtime during critical loading and unloading cycles.

Bearing Support: Precision Alignment

The rear of the FAW Russian Sub-Box Housing Assembly supports the output shaft via the Rear Bearing Cover – Sub-box Output Shaft (Part No. 1701586-A5U). This cover does more than seal the case; it axially locates the massive output bearing. To ensure the correct bearing preload, the assembly utilizes a specific Gasket – Sub-box Output Shaft (Part No. 1701581-A7G) which also acts as a shim. Incorrect shimming here would allow the output shaft to “walk” fore and aft, destroying the range-change synchronizers.

Similarly, the intermediate shafts (countershafts) of the sub-box are supported by the Rear Bearing Cover – Sub-box Intermediate Shaft (Part No. 1701521-A9K). The precise alignment of these shafts is crucial for gear mesh. The FAW Russian Sub-Box Housing Assembly employs a sophisticated selective shimming process using Adjustment Shim – Sub-box Intermediate Shaft (Part Nos. 1701526-A7G through 1701537-A7G). These shims come in minute thickness increments, allowing technicians to dial in the end-play to factory specifications, compensating for manufacturing tolerances and thermal expansion.

Sealing the rotating output shaft against the elements is the Oil Seal Assembly (Part No. 1701605-A0L-C00). In the dusty, muddy environment of a quarry, this seal is the first line of defense. The FAW Russian Sub-Box Housing Assembly specifies a multi-lip seal made from high-grade fluoroelastomer (FKM) to resist the high heat of the output shaft while maintaining flexibility in sub-zero ambient temperatures. A failure of this seal would allow abrasive grit to enter the transmission, destroying the precision bearings within miles.

Signal Logic: The Odometer Drive

Embedded within the FAW Russian Sub-Box Housing Assembly is the vehicle’s speed sensing mechanism. The Driven Gear – Odometer (Part No. 1701646-BSX800) meshes with a drive gear on the output shaft to provide a mechanical rotation proportional to vehicle speed. This rotation is captured by the Speedometer Connector (Part No. 1701447-8A), which interfaces with the electronic speed sensor. Accurate speed data is vital for the driver to maintain safe descent speeds on icy grades.

The sealing of this sensor interface relies on O-ring Rubber Seal (Part No. Q7342416B) and O-ring Rubber Seal (Part No. Q7343530B). These small rubber components play a massive role in the FAW Russian Sub-Box Housing Assembly integrity. Located low on the housing, they are submerged in oil. If they fail, transmission fluid will leak directly onto the prop shaft and parking brake drum. The use of high-quality O-rings ensures that the sensor port remains sealed against both internal oil pressure and external water ingress during pressure washing.

The Fastening Screw (Part No. 1702129-1H) and Spring Washer (Part No. Q40308) lock the odometer drive in place. Even minor vibrations could cause the sensor to back out, leading to signal loss. The FAW Russian Sub-Box Housing Assembly design ensures positive retention of these small but critical instrumentation components, guaranteeing reliable telemetry for the vehicle operator.

Component Breakdown: 108. Sub-Box Housing Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | 1701501FA0L | Sub-box Housing | 1 |

| 2 | Q1841035S | Hexagon Flange Bolt Coarse Shank (Standard) | 16 |

| 3 | 4207010-YQA7GN1 | PTO Assembly | 1 |

| 4 | Q1841025S | Hexagon Flange Bolt Coarse Shank (Standard) | 5 |

| 5 | 1701581-A7G | Gasket – Sub-box Output Shaft | 1 |

| 6 | 1701586-A5U | Rear Bearing Cover – Sub-box Output Shaft | 1 |

| 7 | 1702129-1H | Fastening Screw | 1 |

| 8 | Q40308 | Spring Washer | 1 |

| 9 | 1701605-A0L-C00 | Oil Seal Assembly | 1 |

| 10 | Q1841085S | Hexagon Flange Bolt Coarse Shank (Standard) | 6 |

| 11 | 1701646-BSX800 | Driven Gear – Odometer | 1 |

| 12 | Q7342416B | O-ring Rubber Seal | 2 |

| 13 | Q7343530B | O-ring Rubber Seal | 1 |

| 14 | 1701447-8A | Speedometer Connector | 1 |

| 15 | 1701521-A9K | Rear Bearing Cover – Sub-box Intermediate Shaft | 1 |

| 16 | 1701526-A7G | Adjustment Shim – Sub-box Intermediate Shaft | 1 |

| 17 | Q1841050S | Hexagon Flange Bolt Coarse Shank (Standard) | 2 |

Conclusion: The Rigid Backbone of Range Splitting

The FAW Russian Sub-Box Housing Assembly provides the rigid, precision-machined environment necessary for the transmission’s auxiliary section to function. By integrating the PTO mount, securing the rear bearings, and sealing the output shaft against the elements, this assembly is fundamental to the truck’s versatility and durability. Its design reflects a deep understanding of the challenges posed by heavy loads and arctic temperatures.

For fleet maintenance, the integrity of this housing and its seals is non-negotiable. A damaged bearing cover or a reused oil seal can lead to fluid loss and catastrophic gear failure. By utilizing genuine FAW components and adhering to the precise shimming procedures, operators ensure that their transmission delivers reliable power for the long haul, maintaining the productivity of the CA3250P66K24L1TE5Z fleet.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.