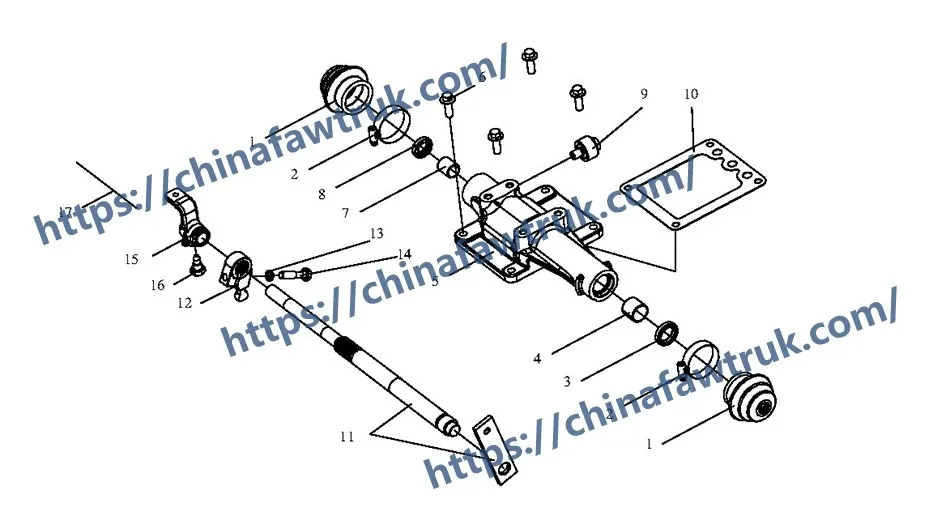

Welcome to this specialized deconstruction of the FAW J6P Roof Panel, the top cover assembly for the CA10TA160M 10-speed transmission. This guide is for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck, analyzing the 17 components that form the FAW J6P Roof Panel, the critical interface between the driver’s shift lever and the gearbox’s internal rails.

The FAW J6P Roof Panel is the “Human-Machine Interface” of the gearbox. Its logic is to translate the driver’s “X-Y” (side-to-side and fore-aft) hand movements into a precise, isolated “Z” (downward) motion onto the correct shift rail. This assembly ensures smooth, precise gear selection and is the key to the entire shift-feel and interlock system.

This group represents the foundational “chassis” of the entire shift lever mechanism. All other components in this list are mounted *inside* or *onto* this single part, the FAW J6P Roof Panel.

1. Component: ‘Top cover’ (1702211A703)

This (Comp 5) is the main ‘Top cover’, the FAW J6P Roof Panel casting. This is a heavy-duty, complex component, precision-cast from iron or aluminum. Its logic is threefold:

The Alignment Logic is its most critical function. The FAW J6P Roof Panel is machined with precise, parallel bores. These bores are the “tunnels” that support the ‘Shift shaft’ (Comp 11) and ‘Select gear arm’ (Comp 15), ensuring they move smoothly and engage the internal rails perfectly.

The Sealing Logic is its second function. This component acts as the final “roof” for the “Upper Cover” assembly, sealing the shift mechanism from the elements. It is sealed to the lower housing by the ‘Gasket’ (Comp 10).

2. Component: ‘Gasket – top cover’ (1702216-A7G)

This (Comp 10) is the main static seal. This precision-cut gasket sits between this FAW J6P Roof Panel (Comp 5) and the ‘Upper Cover’ (from the previous breakdown, item 56). Its logic is to prevent high-temperature oil “splash” from escaping the gearbox and to keep water/dirt *out* of the shift mechanism.

3. Component: ‘Breather plug assy’ (1702240-A7G)

This (Comp 9) is the “lung” of the entire gearbox. This FAW J6P Connecting Element (as it is also a connector) threads into the FAW J6P Roof Panel.

Its Venting Logic is critical. As the gearbox heats up, the oil and air inside expand, creating positive pressure. This ‘Breather plug’ is a one-way valve that “exhales” this pressure. This prevents the pressure from building up and blowing out the main oil seals (like Comp 3 and 8).

This group represents the components in the FAW J6P Roof Panel that are responsible for the driver’s “push-pull” (forward-and-backward) motion. This is the “Y-axis” of the H-pattern, which engages the gear.

1. Component: ‘Shift shaft & arm assy’ (1702220A703)

This (Comp 11) is the core “shift shaft.” The external “arm” of this assembly connects to the driver’s shift lever linkage. The “shaft” portion slides fore-and-aft *inside* the bores of the FAW J6P Roof Panel (Comp 5).

The Actuation Logic is to transfer the “push/pull” motion from the driver, down through the FAW J6P Roof Panel, to the ‘Shift selector head’ (Comp 12).

2. Component: ‘Shift selector head’ (1702231A703)

This (Comp 12) is the “finger” at the bottom of the ‘Shift shaft’ (Comp 11). Its logic is to be the single part that engages the “gates” on the shift rails (housed in the cover *below* this FAW J6P Roof Panel). When the driver pushes forward, this “head” pushes the selected shift rail forward.

3. The “Shift Shaft Bushing & Seal” Group (Comp 3, 4, 7, 8)

This group includes: ‘Top cover oil seal assy – shift shaft’ (Comp 3 & 8) and ‘Sliding bush – top cover’ (Comp 4 & 7).

The Bushing Logic is for smooth operation. The two ‘Sliding bushes’ (Comp 4, 7) are low-friction liners pressed into the FAW J6P Roof Panel (Comp 5). They allow the ‘Shift shaft’ (Comp 11) to slide back and forth with minimal effort and no metal-on-metal contact.

The Dynamic Seal Logic is the job of the two ‘Oil seal assemblies’ (Comp 3, 8). These are critical *dynamic* seals. They are mounted in the FAW J6P Roof Panel to prevent gearbox oil from “splashing” up the shift shaft and leaking out of the top of the transmission.

This group represents the components in the FAW J6P Roof Panel that handle the driver’s “side-to-side” motion. This is the “X-axis” of the H-pattern, which *selects* which shift rail to engage.

1. Component: ‘Select gear arm’ (1702241A703)

This (Comp 15) is the ‘Select gear arm’. This component is also connected to the driver’s shift lever linkage. Its logic is to *rotate* the ‘Shift shaft’ (Comp 11) along its long axis.

This Rotational Logic is what moves the ‘Shift selector head’ (Comp 12) from side-to-side. This action is what “selects” which shift rail (1/R, 2/3, or 4/5) the ‘Shift selector head’ is aligned with, *before* the driver “shifts” (pushes/pulls) it. This is the “selector” part of the FAW J6P Roof Panel mechanism.

2. The “Safety Lock” Group (Comp 16, 17)

This group includes: ‘Fastening screw’ (Comp 16) and ‘Steel wire lock line’ (Comp 17).

The Critical Fastener Logic is their function. The ‘Fastening screw’ (Comp 16) is what locks the ‘Select gear arm’ (Comp 15) to its shaft. Because this fastener is *inside* the FAW J6P Roof Panel, it must *never* come loose.

The ‘Steel wire lock line’ (Comp 17) is a “fail-safe” device. This wire is threaded through a hole in the head of the screw (Comp 16) and twisted, making it physically *impossible* for the screw to vibrate loose. This is a critical safety feature of the FAW J6P Roof Panel assembly.

This final group includes all the miscellaneous hardware that mounts the FAW J6P Roof Panel to the gearbox and connects the external linkages.

1. The “Mounting Bolt” Group (Comp 6, 13, 14)

This group includes: ‘Hexagon flange bolt’ (Comp 6, Qty 4), ‘Spring washer’ (Comp 13, Qty 1), and ‘Hexagon head bolt with guide neck’ (Comp 14, Qty 1).

The Clamping Logic is their function. These are the main bolts that securely fasten the FAW J6P Roof Panel (Comp 5) to the “Upper Cover” (from the previous breakdown, item 56).

The ‘Flange bolts’ (Comp 6) are self-locking and resist vibration. The ‘Guide neck’ bolt (Comp 14) is a high-precision bolt, likely used at a critical alignment point, with a ‘Spring washer’ (Comp 13) to provide constant tension. These ensure the FAW J6P Roof Panel remains rigid and oil-tight.

2. The “Linkage” Group (Comp 1, 2)

This group includes: ‘Dust cover – top cover’ (Comp 1, Qty 2) and ‘Lever transmission type hose clamp’ (Comp 2).

The Protection Logic is the job of the ‘Dust cover’ (Comp 1). These are flexible rubber “bellows” or “boots” that slide over the external shift linkages (like the ‘Select gear arm’). They protect the pivot joints from dirt, sand, and water, which would quickly wear them out.

The Clamping Logic of the ‘Hose clamp’ (Comp 2) is to securely fasten these ‘Dust covers’ (Comp 1) onto the linkages, ensuring a tight seal. These are essential for the long-term reliability of the FAW J6P Roof Panel‘s external mechanism.

The following table provides the complete, detailed breakdown of all 17 component types in the FAW J6P Roof Panel and shift lever assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1702251A703 | Dust cover – top cover | 2 |

| 2 | CQ67560 | Lever transmission type hose clamp | 2 |

| 3 | 1702255A703 | Top cover oil seal assy – shift shaft | 1 |

| 4 | 1702226A703 | Sliding bush – top cover | 1 |

| 5 | 1702211A703 | Top cover | 1 |

| 6 | Q1841030S | Hexagon flange bolt | 4 |

| 7 | 1702227A703 | Sliding bush – top cover | 1 |

| 8 | 1702260A703 | Top cover oil seal assy – shift shaft | 1 |

| 9 | 1702240-A7G | Breather plug assy | 1 |

| 10 | 1702216-A7G | Gasket – top cover | 1 |

| 11 | 1702220A703 | Shift shaft & arm assy | 1 |

| 12 | 1702231A703 | Shift selector head | 1 |

| 13 | Q40310 | Spring washer | 1 |

| 14 | CQ1501045S | Hexagon head bolt with guide neck | 1 |

| 15 | 1702241A703 | Select gear arm | 1 |

| 16 | 1702056-A7G | Fastening screw | 1 |

| 17 | Q50512250 | Steel wire lock line | 1 |

The specifications for the FAW J6P Roof Panel are defined by its function as the primary interface for the manual shift lever, translating driver inputs into mechanical motion.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Roof Panel (Gearbox Top Cover) |

| Associated Gearbox | CA10TA160M (10-Speed) |

| Primary Logic | Translate Shift Lever “X-Y” Motion |

| Core Component (Housing) | ‘Top cover’ (1702211A703) |

| Core Component (Shift) | ‘Shift shaft & arm assy’ (1702220A703) |

| Core Component (Select) | ‘Select gear arm’ (1702241A703) |

| Venting System | ‘Breather plug assy’ (1702240-A7G) |

| Dynamic Seals | ‘Top cover oil seal assy’ (1702255A703, 1702260A703) |

| Static Seal | ‘Gasket – top cover’ (1702216-A7G) |

| Safety Lock System | ‘Steel wire lock line’ (Q50512250) for ‘Fastening screw’ (1702056-A7G) |

| Total Component Types | 17 |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.