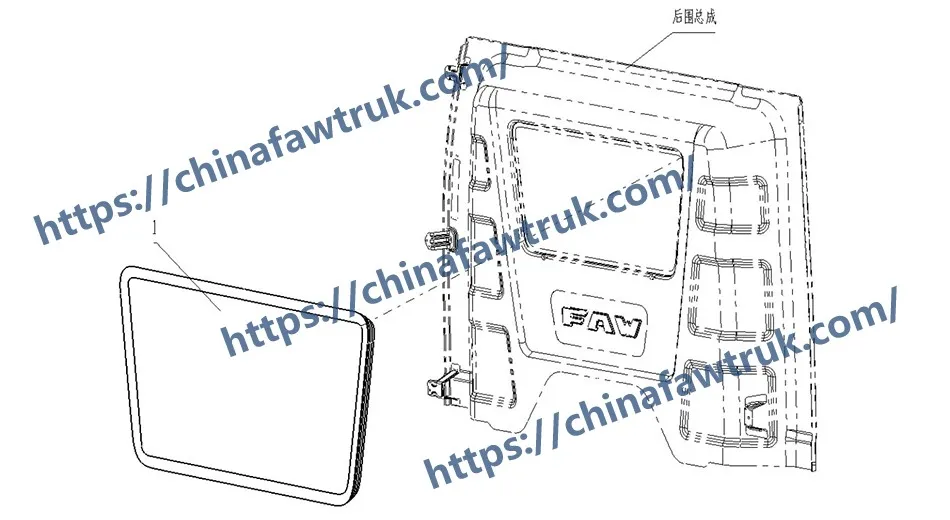

This is the ultimate technical guide to the FAW J6P Rear Window Glass assembly, a crucial component for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction will analyze the single, complete assembly (Part No. 5603010-A86) which is supplied as the minimum serviceable unit.

The FAW J6P Rear Window Glass is far more than a simple pane of glass. It is a structural element of the J6P cab, designed to provide critical rearward visibility while protecting the operator from the elements, noise, and debris. This guide will explore the logic behind this single assembly, breaking down its visual, safety, and sealing functions.

The entire system is centered around the single core component. Although supplied as one part, its logic is twofold: the glass panel itself and its integrated sealing system.

1. Component: ‘Rear window glass assembly’ (5603010-A86) – Qty 1

This is the complete, non-serviceable FAW J6P Rear Window Glass assembly. The name ‘assembly’ is critical, as it implies that this part is a pre-fabricated unit, not just a raw pane of glass.

The Visibility Logic is the primary user-facing function. The rear window of a dump truck is essential for safety, allowing the operator to check the blind spot, observe the dumper body’s position during operation, and safely reverse the vehicle on a busy work site. The FAW J6P Rear Window Glass is manufactured to precise optical standards to ensure distortion-free viewing.

The Safety Logic is a non-negotiable legal and functional requirement. This glass is not standard annealed glass. It is high-strength automotive safety glass, almost certainly Tempered Glass. This means it has been heat-treated to be several times stronger than standard glass.

In the event of a severe impact, tempered glass is designed to shatter into thousands of small, blunt-edged pebbles. This ‘dicing’ pattern is a critical safety feature that prevents the occupants from being injured by large, sharp shards of glass. This makes the FAW J6P Rear Window Glass a critical safety-of-life component.

The Structural Logic is often overlooked. The J6P cab is a complete structural unit, and its windows contribute to its overall rigidity. The FAW J6P Rear Window Glass is bonded to the cab frame, becoming a stressed member of the chassis. This bonding adds to the cab’s stiffness, reducing flex and improving its performance in a potential rollover event.

Since Part No. 5603010-A86 is an ‘assembly’, it includes the critical sealing mechanism. This is not listed separately because it is factory-integrated with the FAW J6P Rear Window Glass.

The Sealing Logic is fundamental. This component’s secondary role is to create an impermeable barrier against the elements. The integrated seal, typically a pre-molded EPDM (Ethylene Propylene Diene Monomer) rubber gasket, is bonded to the perimeter of the glass.

This creates a watertight and airtight seal, preventing rain, dust, mud, and exhaust fumes from entering the operator’s cab. On a dump truck working in harsh quarries, a failed seal can quickly make the cab environment unbearable. The design of the FAW J6P Rear Window Glass assembly ensures this seal is perfect.

The Acoustic Isolation Logic is another key function of the seal. The EPDM rubber gasket is not just a water stop; it is also a vibration damper. It isolates the glass panel from the metal cab frame, preventing high-frequency vibrations from the engine and chassis from being transmitted directly to the glass.

This damping effect dramatically reduces the resonance and noise inside the cab, lowering driver fatigue. A solid glass-to-metal contact would result in a loud, vibrating panel. The integrated seal of the FAW J6P Rear Window Glass is engineered to absorb these vibrations.

The Durability Logic of the seal is also paramount. EPDM rubber is chosen specifically for its superior resistance to UV radiation from sunlight, ozone, and extreme temperatures. This ensures the seal remains flexible and effective for the entire service life of the truck, without cracking or shrinking.

The part is supplied as a single assembly for a crucial reason: service. Automotive glass installation is a specialized task that is critical to vehicle safety and performance.

The Service Logic is that this FAW J6P Rear Window Glass is designed to be replaced as a single unit. When the original glass is damaged, a technician does not attempt to salvage the old seal. The entire damaged assembly is cut out, and the new 5603010-A86 assembly is installed.

This method, often called “direct glazing,” ensures a perfect, leak-free fit every time. It eliminates the variables and potential failure points of trying to manually fit a new seal. The FAW J6P Rear Window Glass assembly is designed for a clean, reliable, and fast replacement.

The Bonding Logic is the technical process of installation. This FAW J6P Rear Window Glass is not held in by a simple pressure-fit gasket. It is chemically bonded to the cab’s pinch weld (the metal flange around the window opening) using a high-modulus polyurethane adhesive.

This adhesive is the key to the entire system. It forms a powerful, flexible bond that permanently joins the glass to the cab, restoring the original structural integrity. The installation process is precise: the old adhesive must be removed, the new glass and frame must be cleaned, and a special primer must be applied.

The Curing Logic is the final step. The polyurethane adhesive requires time to cure (harden) to reach its full strength. A vehicle should not be operated immediately after installation. This curing time is essential to ensure the FAW J6P Rear Window Glass is properly bonded and can withstand the massive forces and vibrations of a dump truck.

The following table provides the complete, detailed breakdown of all component types in the FAW J6P Rear Window Glass assembly (System 136) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5603010-A86 | Rear window glass assembly | 1 |

The specifications for the FAW J6P Rear Window Glass are defined by its role as a structural, safety, and sealing component of the J6P cab.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Rear Window Glass |

| Assembly Reference | 136 |

| Primary Logic | Cab Integrity, Operator Visibility, & Sealing |

| Core Component | ‘Rear window glass assembly’ (5603010-A86) |

| Glass Type | Tempered Automotive Safety Glass |

| Seal Type | Integrated EPDM Rubber Gasket (Pre-molded) |

| Installation Method | Direct Glazing (Bonded with Polyurethane Adhesive) |

| Serviceability | Replaceable as a single assembly |

| Total Component Types | 1 (as a complete assembly) |

| Associated System | Cab Structure & Glazing |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.