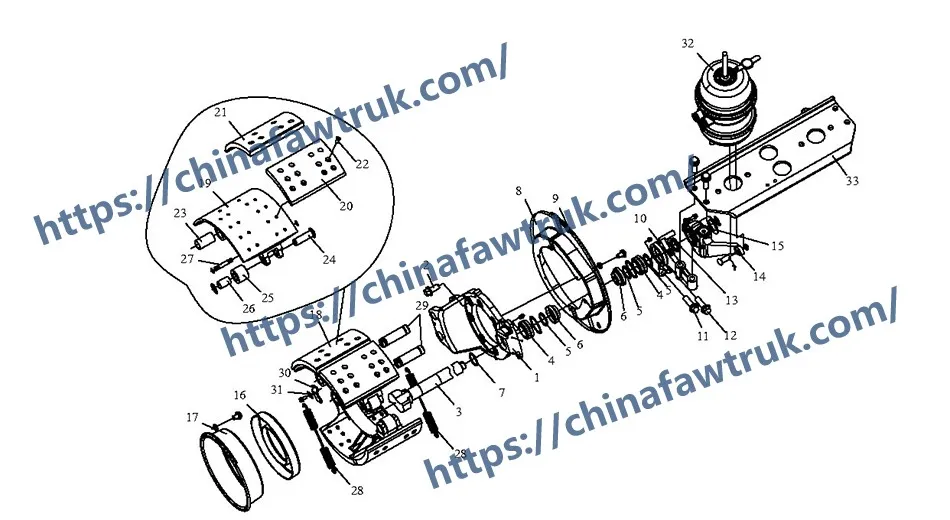

This is a complete technical guide to the FAW J6P Rear Wheel Brake (Model 3502024-48W) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 33 serviceable component types that form the complete S-cam brake assembly for the tandem drive axles.

The FAW J6P Rear Wheel Brake is a heavy-duty, S-cam “drum” brake system. This robust design is the industry standard for heavy-duty drive axles, prized for its durability, high stopping torque, and serviceability. Its primary function is to convert the kinetic energy of the 25-ton truck into heat, safely bringing the vehicle to a stop. It works by using compressed air to force a set of brake shoes and linings against the inner surface of the rotating brake drum. This is the main service brake for the vehicle.

This deconstruction will analyze the key serviceable assemblies of the FAW J6P Rear Wheel Brake, including the pneumatic actuator (spring brake chamber), the mechanical linkage (S-cam and slack adjuster), the friction components (brake shoes and linings), and the stationary foundation (axle boss). A properly maintained FAW J6P Rear Wheel Brake is the most critical safety system on the tandem axles, and its condition is non-negotiable for safe operation. Every part of the FAW J6P Rear Wheel Brake must be inspected regularly.

This is the “muscle” of the FAW J6P Rear Wheel Brake. This component converts the pneumatic signal from the brake pedal into powerful mechanical force and also provides the parking brake function.

1. Component: ‘Rear left/right spring cylinder assy’ (3530015-A0E, 3530010-A0E)

This (Comp 32) is the complete air brake chamber, also known as a “spring brake” or “piggyback” assembly. The Pneumatic-to-Mechanical Logic is its primary function: when the driver presses the brake pedal, compressed air fills the service chamber, pushing a rod out to apply the brakes.

The Parking Brake Logic is its second, critical function. A powerful internal spring is held compressed by constant air pressure. When the driver pulls the park brake, this air is released, and the spring mechanically expands, forcing the pushrod out and locking the FAW J6P Rear Wheel Brake. A leaking diaphragm in this chamber is a common failure point and will result in a dangerous air leak and a loss of braking power. This is a critical safety component of the FAW J6P Rear Wheel Brake.

2. Component: ‘Support Plate – Spring Brake Cylinder’ (3502126A483)

This (Comp 33) is the heavy-duty bracket that mounts the spring brake chamber (Comp 32) to the axle boss. It must be strong enough to withstand the full force of both the service and parking brake applications.

This group of components forms the stationary foundation of the FAW J6P Rear Wheel Brake. It bolts directly to the axle housing and serves as the anchor point for the brake shoes.

1. Component: ‘Left axle boss’ (3503127-A0E) & ‘Rear brake spider’ (3502021-A0E)

This (Comp 1, 10) is the “spider” or “backing plate”. It is a massive, single-piece cast iron component that bolts to the axle. Its Anchor Point Logic is to absorb all the torque and forces generated by the braking action. The brake shoes (Comp 18) are anchored to this spider, and it is the component that the S-cam (Comp 3) passes through. A cracked spider is a critical failure of the FAW J6P Rear Wheel Brake.

2. Component: ‘Spacer – axle boss support’ (3502123-A0E) – Qty 2

This (Comp 13) is a precision spacer used to properly position the axle boss on the axle housing, ensuring the FAW J6P Rear Wheel Brake is perfectly aligned with the brake drum.

3. Component: ‘Rear brake dust pan’ (3502031-A0E) & ‘Front dust pan’ (3502032-A0E)

This (Comp 8 & 9) is the dust shield assembly. These thin metal plates bolt to the spider (Comp 1) and partially enclose the FAW J6P Rear Wheel Brake to protect the shoes and drum from contamination by rocks, mud, and road debris, which is critical in a dump truck application.

This is the “wear” part of the FAW J6P Rear Wheel Brake. These components are designed to be sacrificed to create the friction needed to stop the truck.

1. Component: ‘Brake shoe with roller assy’ (3502375-A0E) – Qty 4

This (Comp 18) is the complete brake shoe, which includes the steel “web” and the pre-riveted friction lining. The FAW J6P Rear Wheel Brake uses two of these shoes (primary and secondary) per wheel. This assembly also includes the ‘Roller’ (Comp 26) and ‘Roller Shaft’ (Comp 24).

2. Component: ‘Rear brake lining I’ (3502406-A0E) & ‘Rear brake lining II’ (3502407-A0E) – Qty 4 each

This (Comp 20, 21) is the serviceable friction material. The Friction Logic involves two different lining types (I and II), which suggests a “leading/trailing” or “primary/secondary” shoe design for the FAW J6P Rear Wheel Brake. One lining is more aggressive to provide the initial bite, while the other is designed for sustained friction and heat dissipation.

3. Component: ‘Rivet – brake lining’ (3502408-A0E) – Qty 112

This (Comp 22) is the set of 112 rivets used to attach the ‘Brake linings’ (Comp 20, 21) to the steel brake shoe web (Comp 19). This riveted design is common in heavy-duty FAW J6P Rear Wheel Brake systems as it is strong and allows for the linings to be replaced.

4. Component: ‘Return spring’ (3502436-A0E) & ‘Anchor pin’ (3502398-A0E)

This (Comp 28, 27) is the retraction system. The heavy-duty ‘Return spring’ connects to the ‘Anchor pin’ (Comp 27) and aggressively pulls the brake shoes back away from the brake drum the instant the driver releases the pedal. A weak or broken return spring will cause the FAW J6P Rear Wheel Brake to “drag,” leading to extreme overheating and failure.

This group of components forms the mechanical link between the air chamber (Core 1) and the brake shoes (Core 3). It translates the linear push from the air chamber into a rotary motion that spreads the shoes apart. This is the heart of the FAW J6P Rear Wheel Brake.

1. Component: ‘Left/Right slack adjuster assy’ (3502205-A6E, 3502210-A6E) – Qty 1 each

This (Comp 14) is the “slack adjuster”. This Self-Adjusting Logic is a key feature of a modern FAW J6P Rear Wheel Brake. As the brake linings (Comp 20, 21) wear, this device automatically adjusts its angle on the camshaft to ensure the “slack” (distance) between the lining and the drum remains minimal. This provides a consistent, responsive brake pedal.

2. Component: ‘Left/Right rear brake camshaft’ (3502151-A6E, 3502152-A6E) – Qty 1 each

This (Comp 3) is the ‘S-cam’. This is a forged steel shaft with an “S” shaped head at one end. As the slack adjuster (Comp 14) rotates this shaft, the “S” shape pushes against the ‘Brake shoe rollers’ (Comp 26), forcing the brake shoes apart and into the drum. This is the final mechanical force multiplication in the FAW J6P Rear Wheel Brake.

3. Component: ‘Camshaft bearing assy’ (3502135-A0E) & ‘Seals’ (3502153-A0E)

This (Comp 4, 5, 7) is the bearing and seal system for the camshaft. The camshaft must rotate smoothly within the axle boss (Comp 1). These ‘Bearings’ (Comp 4) and ‘Oil seals’ (Comp 5, 7) ensure a low-friction rotation and prevent water and grit from entering and seizing the FAW J6P Rear Wheel Brake camshaft. Regular greasing via the ‘Grease nipple’ (Comp 1) is essential.

The following table provides the complete, detailed breakdown of all 33 component groups in the FAW J6P Rear Wheel Brake assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for any service of the FAW J6P Rear Wheel Brake.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| – | 3502024-48W | Rear brake assy | 1 |

| 1 | 3502021-A0E | Rear brake spider | 2 |

| CQ70001 | Straight type grease nipple | 2 | |

| Q966555 | Steel ball | 2 | |

| 2 | 3502038-487 | Lock bolt | 14 |

| 3 | 3502151-A6E / 3502152-A6E | Left/Right rear brake camshaft | 1 each |

| 4 | 3502135-A0E | Camshaft joint bearing assy | 4 |

| 5 | 3502153-A0E | Oil seal – camshaft support | 6 |

| 6 | 3502124-A0E | Seat – oil seal | 4 |

| 7 | 3502153-A0E | Oil seal – brake camshaft | 2 |

| 8 | 3502031-A0E | Rear brake rear dust pan | 2 |

| 9 | 3502032-A0E | Rear brake front dust pan | 2 |

| 10 | 3502125-A0E | Rear axle left camshaft bracket assy | 1 |

| 13 | 3502123-A0E | Spacer – camshaft bracket | 2 |

| 14 | 3502205-A6E / 3502210-A6E | Left/Right rear slack adjuster assy | 1 each |

| 15 | 3501251-A0S | Spacer – brake slack adjuster | 2 |

| 16 | 3502432-A0E | Oil baffle plate 2 | 2 |

| 17 | 3502431AA0E | Oil baffle plate 1 | 2 |

| 18 | 3502375-A0E | Brake shoe with roller assy | 4 |

| 19 | 3502391-A0E | Rear brake shoe | 4 |

| 20 | 3502406-A0E | Rear friction lining I | 4 |

| 21 | 3502407-A0E | Rear friction lining II | 4 |

| 22 | 3502408-A0E | Rivet – brake lining | 112 |

| 23 | 3501396-A0S | Bushing – rear brake shoe | 4 |

| 24 | 3502394-A0E | Roller shaft | 4 |

| 25 | 3502393-A0E | Bushing-roller | 4 |

| 26 | 3502392-A0E | Roller | 4 |

| 27 | 3502398-A0E | Return spring anchor pin | 4 |

| 28 | 3502436-A0E | Return spring | 4 |

| 29 | 3501051-A0S | Shoe pin | 4 |

| 30 | 3501052-A0S | Baffle plate – shoe pin | 2 |

| 31 | 3501053-A0S | Lock plate – shoe pin baffle | 2 |

| 32 | 3530015-A0E / 3530010-A0E | Left/Right rear spring cylinder assy | 1 each |

| 33 | 3502126A483 | Support plate – spring brake cylinder | 1 |

The specifications for the FAW J6P Rear Wheel Brake are defined by its robust S-cam, air-actuated design, built for the heavy-duty service of a tandem drive axle. A properly adjusted and maintained FAW J6P Rear Wheel Brake is essential for vehicle safety.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Rear Wheel Brake |

| Brake Type | S-Cam Drum Brake |

| Actuation | Pneumatic – ‘Spring cylinder assy’ (3530015-A0E) |

| Actuation Linkage | ‘Rear brake camshaft’ (3502151-A6E) |

| Adjustment | ‘Automatic slack adjuster assy’ (3502205-A6E) |

| Friction Component | ‘Brake shoe with roller assy’ (3502375-A0E) |

| Friction Material | ‘Rear friction lining I’ (3502406-A0E) & ‘II’ (3502407-A0E) |

| Foundation | ‘Rear brake spider’ (3502021-A0E) |

| Total Component Types | 33 |

| Associated System | Rear Axle / Braking System. The FAW J6P Rear Wheel Brake is the core. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.