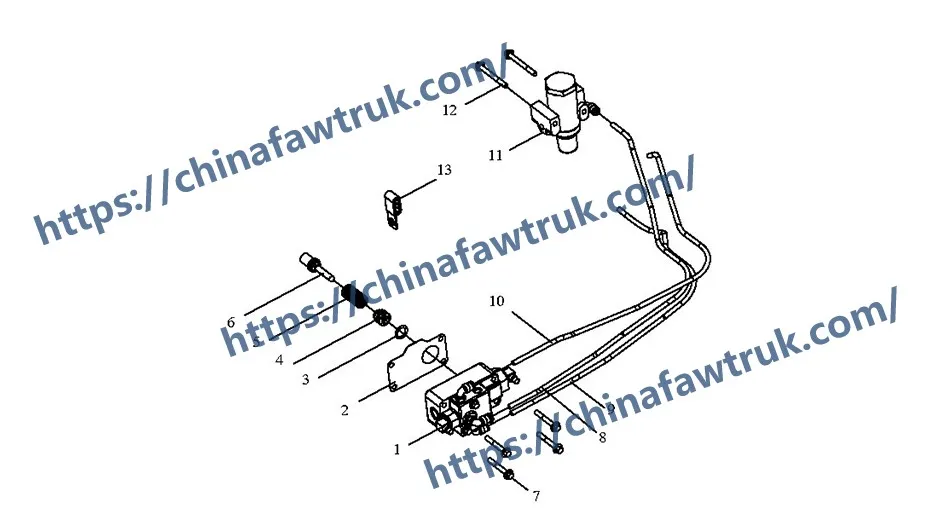

Welcome to this expert deconstruction of the FAW J6P Hose, Valve, and Connector assembly, the complete pneumatic “plumbing” circuit for the CA10TA160M 10-speed transmission. This system is a core part of the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide deconstructs all 13 components, focusing on the FAW J6P Hose lines.

The FAW J6P Hose assembly is the “circulatory system” for the Hi/Lo range shifter. Its logic is to safely transport high-pressure compressed air from the control valves to the range cylinder, ensuring fast, reliable shifts. The integrity of this FAW J6P Hose system is critical for protecting the gearbox and ensuring driver control.

This group represents the core “plumbing” of the entire range-shift system. Its logic is to be the flexible, durable conduit that moves high-pressure air from the “brain” (the valves) to the “muscle” (the range cylinder). This is the primary role of the FAW J6P Hose components.

1. Component: ‘Inlet hose – high gear’ (1702343-A7G)

This (Comp 9) is the dedicated “High Range” air line. This FAW J6P Hose connects one output port of the ‘Follower valve’ (Comp 1) directly to the “engage high” port on the ‘Auxiliary Gearbox Range Cylinder’.

The Durability Logic is its key feature. This is not a simple rubber tube. It is a multi-layer, reinforced pneumatic hose designed to withstand constant vibration, high engine-bay temperatures, and repeated pressure cycles of 120+ PSI. It must also be resistant to oil and diesel-fuel mist. A failure in this specific FAW J6P Hose means no high range.

2. Component: ‘Inlet hose – low gear’ (1702342-A7G)

This (Comp 10) is the second critical “Low Range” air line. This FAW J6P Hose connects the *other* output port of the ‘Follower valve’ (Comp 1) to the “engage low” port on the dual-action range cylinder.

The Dual-Path Logic is essential. The range cylinder is “powered” in both directions (no spring return). This requires two separate, dedicated FAW J6P Hose lines: one to push the piston (e.g., engage High) and one to pull it (engage Low). A failure in this hose (Comp 10) would mean the driver could shift *into* high range, but could not shift back *out* into low range.

3. Component: ‘Hose clamp’ (1702391-A7G)

This (Comp 13) is a simple “P-clamp” or ‘Hose clamp’, but it is a critical safety component for the FAW J6P Hose system.

The Anti-Chafing Logic is its sole purpose. This clamp is used to securely bolt the FAW J6P Hose lines (Comp 9 and 10) to a fixed point on the gearbox housing or chassis. This prevents the hoses from vibrating, rubbing against the spinning driveshaft, or resting on the hot exhaust system. This one, simple clamp prevents a “rub-through” hole that would cause a total failure of the range-shift system.

Before compressed air can be trusted to enter the precision-engineered FAW J6P Hose and valve system, it must be “conditioned” (cleaned and dried). This is the job of the air filter assembly.

1. Component: ‘Air filter & connector assy’ (1702380-A7G)

This (Comp 11) is the “lung” of the entire pneumatic shift system. It is the first component in the circuit, receiving its air supply from the truck’s main tanks. It is mounted to the gearbox housing by two ‘Hexagon flange bolts’ (Comp 12).

The Protection Logic is its critical function. The compressed air in a truck’s main tanks is notoriously “dirty.” It contains water (from atmospheric condensation), atomized oil (from the air compressor’s crankcase), and small rust/scale particles.

This ‘Air filter’ (Comp 11) contains a fine filter element that “scrubs” this air, trapping the water, oil, and debris. This clean, dry air is then fed to the ‘Follower valve’ (Comp 1) and the rest of the FAW J6P Hose circuit.

Without this filter, the delicate rubber O-rings and tight-tolerance spools inside the ‘Follower valve’ and ‘Neutral gear switch’ (Comp 6) would quickly become fouled with an oily sludge. This would cause the valves to stick, leading to slow, erratic, or completely failed range shifts. This filter protects every component in the FAW J6P Hose system.

This group contains the “brains” of the FAW J6P Hose system. These valves receive signals from the driver and the gearbox, and then “decide” when and where to send the compressed air.

1. Component: ‘Follower valve assy’ (1702320-A7G)

This (Comp 1) is the main “actuator” valve, also known as a slave valve. It is a high-volume air relay. Its “logic” is to receive a small, low-volume “pilot” signal (from the driver’s Hi/Lo switch) and use it to trigger a much larger internal valve.

This main valve then releases a high-volume blast of air into the correct FAW J6P Hose (Comp 9 for Hi, Comp 10 for Lo) to power the range cylinder. This relay system ensures an “instant” shift.

2. Component: ‘Neutral gear switch – follower valve assy’ (1702337-A7G)

This (Comp 6) is the critical “safety interlock” for the entire FAW J6P Hose system. It is a small plunger switch (with its ‘Sleeve’, Comp 4, and ‘Spring’, Comp 5) that reads the physical position of the main gearbox shift rails.

Its Interlock Logic is simple: it *blocks* the pilot signal to the ‘Follower valve’ (Comp 1) *unless* the main gearbox is in neutral. This prevents a driver from attempting a range-shift while “in gear,” an action that would destroy the range synchronizers. This valve is a critical “permission” switch for the FAW J6P Hose circuit.

3. Component: ‘Inlet hose control valve’ (1702341-A7G)

This (Comp 8) is another logic valve in the FAW J6P Hose circuit. It is likely a “one-way check valve” or “pressure protection valve.” Its logic is to “shape” the air pulse, possibly to act as a quick-exhaust to speed up shifts, or to prevent air from “back-feeding” from the cylinder to the main valve.

This final group contains all the static seals and high-tensile hardware that physically mount the FAW J6P Hose and valve components to the gearbox, ensuring a leak-proof and vibration-proof assembly.

1. The “Static Seal” Group (Comp 2, 3)

This group includes: ‘Gasket – follower valve assy’ (Comp 2) and ‘O-ring’ (Comp 3). These are the two primary static seals for the FAW J6P Hose control system.

The ‘Gasket’ (Comp 2) provides the large “face seal” for the main ‘Follower valve’ (Comp 1), providing both an air and oil seal. The ‘O-ring’ (Comp 3) provides the “radial seal” for the ‘Neutral gear switch’ (Comp 6) as it threads into the gearbox housing.

2. The “Fastener” Group (Comp 7, 12)

This group includes: ‘Hexagon flange bolt’ (Comp 7, Qty 4) and ‘Hexagon flange bolt’ (Comp 12, Qty 2).

The Flange Bolt Logic is a vibration-resistant design. These are not standard bolts. They have a “flange” (a built-in washer) that distributes clamping force over a wider area.

The four ‘Hexagon flange bolts’ (Comp 7) are used to mount the main ‘Follower valve’ (Comp 1), compressing the ‘Gasket’ (Comp 2). The two ‘Hexagon flange bolts’ (Comp 12) are used to mount the ‘Air filter’ (Comp 11). These fasteners are critical to securing the FAW J6P Hose and valve system against constant engine vibration.

The following table provides the complete, detailed breakdown of all 13 component types in the FAW J6P Hose and valve assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1702320-A7G | Follower valve assy | 1 |

| 2 | 1702321-A7G | Gasket – follower valve assy | 1 |

| 3 | 1702332-A7G | O-ring | 1 |

| 4 | 1702333-A7G | Sleeve – neutral gear switch | 1 |

| 5 | 1702336-A7G | Spring – neutral gear switch | 1 |

| 6 | 1702337-A7G | Neutral gear switch – follower valve assy | 1 |

| 7 | Q1840645S | Hexagon flange bolt | 4 |

| 8 | 1702341-A7G | Inlet hose control valve | 1 |

| 9 | 1702343-A7G | Inlet hose – high gear | 1 |

| 10 | 1702342-A7G | Inlet hose – low gear | 1 |

| 11 | 1702380-A7G | Air filter & connector assy | 1 |

| 12 | Q1840660S | Hexagon flange bolt | 2 |

| 13 | 1702391-A7G | Hose clamp | 1 |

The specifications for the FAW J6P Hose assembly are defined by its function as the complete pneumatic control and transport system for the CA10TA160M’s Hi/Lo range selector.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Hose, Valve & Connector Assembly |

| Associated Gearbox | CA10TA160M (10-Speed) |

| Primary Logic | Pneumatic Air Transport for Range Shifting |

| Core Hoses | ‘Inlet hose – high gear’ (1702343-A7G), ‘Inlet hose – low gear’ (1702342-A7G) |

| Air Conditioning | ‘Air filter & connector assy’ (1702380-A7G) |

| Main Actuator Valve | ‘Follower valve assy’ (1702320-A7G) |

| Safety System | ‘Neutral gear switch’ (1702337-A7G) |

| Hose Retention | ‘Hose clamp’ (1702391-A7G) |

| Total Component Types | 13 |

| Associated System | Auxiliary Gearbox Range Cylinder |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.