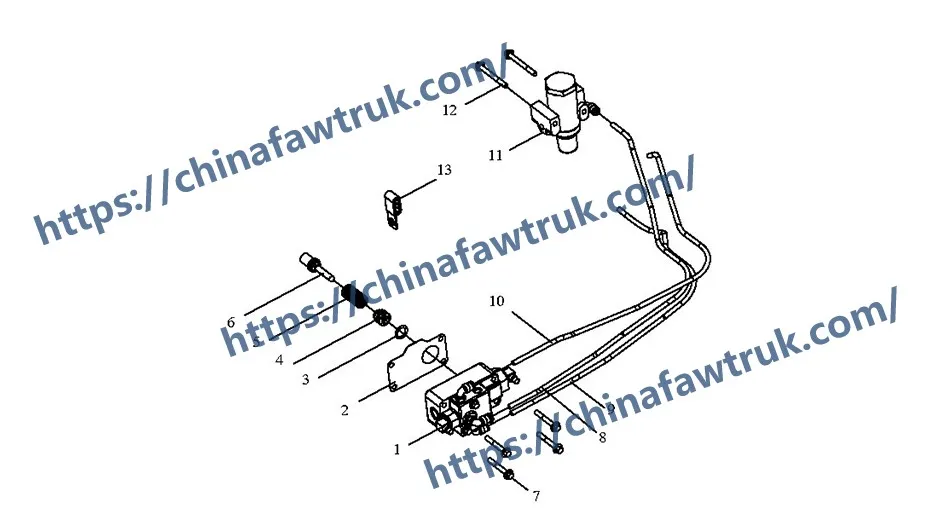

Welcome to this expert deconstruction of the Mangueira FAW J6P, Válvula, e montagem do conector, the complete pneumatic “encanamento” circuit for the CA10TA160M 10-speed transmission. This system is a core part of the FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. This guide deconstructs all 13 componentes, focusing on the Mangueira FAW J6P linhas.

O Mangueira FAW J6P assembly is the “circulatory system” for the Hi/Lo range shifter. Its logic is to safely transport high-pressure compressed air from the control valves to the range cylinder, ensuring fast, reliable shifts. The integrity of this Mangueira FAW J6P system is critical for protecting the gearbox and ensuring driver control.

This group represents the core “encanamento” of the entire range-shift system. Its logic is to be the flexible, durable conduit that moves high-pressure air from the “cérebro” (as válvulas) para o “músculo” (the range cylinder). This is the primary role of the Mangueira FAW J6P componentes.

1. Componente: ‘Inlet hose – alta velocidade’ (1702343-A7G)

Esse (Comp. 9) is the dedicated “High Range” air line. Esse Mangueira FAW J6P connects one output port of the ‘Follower valve’ (Comp. 1) directly to the “engage high” port on the ‘Auxiliary Gearbox Range Cylinder’.

O Durability Logic is its key feature. This is not a simple rubber tube. It is a multi-layer, reinforced pneumatic hose designed to withstand constant vibration, high engine-bay temperatures, and repeated pressure cycles of 120+ PSI. It must also be resistant to oil and diesel-fuel mist. A failure in this specific Mangueira FAW J6P means no high range.

2. Componente: ‘Inlet hose – marcha baixa’ (1702342-A7G)

Esse (Comp. 10) is the second critical “Low Range” air line. Esse Mangueira FAW J6P connects the *other* output port of the ‘Follower valve’ (Comp. 1) para o “engage low” port on the dual-action range cylinder.

O Dual-Path Logic é essencial. The range cylinder is “powered” in both directions (no spring return). This requires two separate, dedicated Mangueira FAW J6P linhas: one to push the piston (Por exemplo, engage High) and one to pull it (engage Low). A failure in this hose (Comp. 10) would mean the driver could shift *into* high range, but could not shift back *out* into low range.

3. Componente: ‘Hose clamp’ (1702391-A7G)

Esse (Comp. 13) é um simples “P-clamp” or ‘Hose clamp’, but it is a critical safety component for the Mangueira FAW J6P sistema.

O Anti-Chafing Logic is its sole purpose. This clamp is used to securely bolt the Mangueira FAW J6P linhas (Comp. 9 e 10) to a fixed point on the gearbox housing or chassis. This prevents the hoses from vibrating, rubbing against the spinning driveshaft, or resting on the hot exhaust system. This one, simple clamp prevents a “rub-through” hole that would cause a total failure of the range-shift system.

Before compressed air can be trusted to enter the precision-engineered Mangueira FAW J6P and valve system, deve ser “conditioned” (cleaned and dried). This is the job of the air filter assembly.

1. Componente: ‘Filtro de ar & connector assy’ (1702380-A7G)

Esse (Comp. 11) é o “pulmão” of the entire pneumatic shift system. It is the first component in the circuit, receiving its air supply from the truck’s main tanks. It is mounted to the gearbox housing by two ‘Hexagon flange bolts’ (Comp. 12).

O Protection Logic is its critical function. The compressed air in a truck’s main tanks is notoriously “dirty.” It contains water (from atmospheric condensation), atomized oil (from the air compressor’s crankcase), and small rust/scale particles.

This ‘Air filter’ (Comp. 11) contains a fine filter element that “scrubs” this air, trapping the water, óleo, e detritos. This clean, dry air is then fed to the ‘Follower valve’ (Comp. 1) and the rest of the Mangueira FAW J6P circuito.

Without this filter, the delicate rubber O-rings and tight-tolerance spools inside the ‘Follower valve’ and ‘Neutral gear switch’ (Comp. 6) would quickly become fouled with an oily sludge. This would cause the valves to stick, leading to slow, erratic, or completely failed range shifts. This filter protects every component in the Mangueira FAW J6P sistema.

This group contains the “cérebros” do Mangueira FAW J6P sistema. These valves receive signals from the driver and the gearbox, and then “decide” when and where to send the compressed air.

1. Componente: ‘Follower valve assy’ (1702320-A7G)

Esse (Comp. 1) é o principal “atuador” válvula, also known as a slave valve. It is a high-volume air relay. Isso é “lógica” is to receive a small, low-volume “piloto” sinal (from the driver’s Hi/Lo switch) and use it to trigger a much larger internal valve.

This main valve then releases a high-volume blast of air into the correct Mangueira FAW J6P (Comp. 9 for Hi, Comp. 10 for Lo) to power the range cylinder. This relay system ensures an “instant” mudança.

2. Componente: ‘Neutral gear switch – follower valve assy’ (1702337-A7G)

Esse (Comp. 6) is the critical “safety interlock” for the entire Mangueira FAW J6P sistema. It is a small plunger switch (with its ‘Sleeve’, Comp. 4, and ‘Spring’, Comp. 5) that reads the physical position of the main gearbox shift rails.

Isso é Interlock Logic é simples: it *blocks* the pilot signal to the ‘Follower valve’ (Comp. 1) *unless* the main gearbox is in neutral. This prevents a driver from attempting a range-shift while “in gear,” an action that would destroy the range synchronizers. This valve is a critical “permission” switch for the Mangueira FAW J6P circuito.

3. Componente: ‘Inlet hose control valve’ (1702341-A7G)

Esse (Comp. 8) is another logic valve in the Mangueira FAW J6P circuito. It is likely a “one-way check valve” ou “pressure protection valve.” Its logic is to “shape” the air pulse, possibly to act as a quick-exhaust to speed up shifts, or to prevent air from “back-feeding” from the cylinder to the main valve.

This final group contains all the static seals and high-tensile hardware that physically mount the Mangueira FAW J6P and valve components to the gearbox, ensuring a leak-proof and vibration-proof assembly.

1. O “Static Seal” Grupo (Comp. 2, 3)

Este grupo inclui: ‘Gasket – follower valve assy’ (Comp. 2) and ‘O-ring’ (Comp. 3). These are the two primary static seals for the Mangueira FAW J6P sistema de controle.

The ‘Gasket’ (Comp. 2) provides the large “face seal” for the main ‘Follower valve’ (Comp. 1), providing both an air and oil seal. The ‘O-ring’ (Comp. 3) provides the “radial seal” for the ‘Neutral gear switch’ (Comp. 6) as it threads into the gearbox housing.

2. O “Fixador” Grupo (Comp. 7, 12)

Este grupo inclui: ‘Hexagon flange bolt’ (Comp. 7, Quantidade 4) and ‘Hexagon flange bolt’ (Comp. 12, Quantidade 2).

O Flange Bolt Logic is a vibration-resistant design. Estes não são parafusos padrão. They have a “mesa” (a built-in washer) that distributes clamping force over a wider area.

The four ‘Hexagon flange bolts’ (Comp. 7) are used to mount the main ‘Follower valve’ (Comp. 1), compressing the ‘Gasket’ (Comp. 2). The two ‘Hexagon flange bolts’ (Comp. 12) are used to mount the ‘Air filter’ (Comp. 11). These fasteners are critical to securing the Mangueira FAW J6P and valve system against constant engine vibration.

A tabela a seguir fornece o completo, detalhamento de todos 13 tipos de componentes no Mangueira FAW J6P and valve assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 1702320-A7G | Follower valve assy | 1 |

| 2 | 1702321-A7G | Junta – follower valve assy | 1 |

| 3 | 1702332-A7G | Anel-O | 1 |

| 4 | 1702333-A7G | Manga – neutral gear switch | 1 |

| 5 | 1702336-A7G | Primavera – neutral gear switch | 1 |

| 6 | 1702337-A7G | Neutral gear switch – follower valve assy | 1 |

| 7 | Q1840645S | Parafuso de flange hexagonal | 4 |

| 8 | 1702341-A7G | Inlet hose control valve | 1 |

| 9 | 1702343-A7G | Inlet hose – alta velocidade | 1 |

| 10 | 1702342-A7G | Inlet hose – marcha baixa | 1 |

| 11 | 1702380-A7G | Filtro de ar & connector assy | 1 |

| 12 | Q1840660S | Parafuso de flange hexagonal | 2 |

| 13 | 1702391-A7G | Grampo de mangueira | 1 |

As especificações para o Mangueira FAW J6P assembly are defined by its function as the complete pneumatic control and transport system for the CA10TA160M’s Hi/Lo range selector.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | Mangueira FAW J6P, Válvula & Conjunto do conector |

| Caixa de velocidades associada | CA10TA160M (10-Velocidade) |

| Lógica Primária | Pneumatic Air Transport for Range Shifting |

| Core Hoses | ‘Inlet hose – alta velocidade’ (1702343-A7G), ‘Inlet hose – marcha baixa’ (1702342-A7G) |

| Air Conditioning | ‘Filtro de ar & connector assy’ (1702380-A7G) |

| Main Actuator Valve | ‘Follower valve assy’ (1702320-A7G) |

| Safety System | ‘Neutral gear switch’ (1702337-A7G) |

| Hose Retention | ‘Hose clamp’ (1702391-A7G) |

| Total de tipos de componentes | 13 |

| Sistema Associado | Cilindro de alcance da caixa de câmbio auxiliar |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.