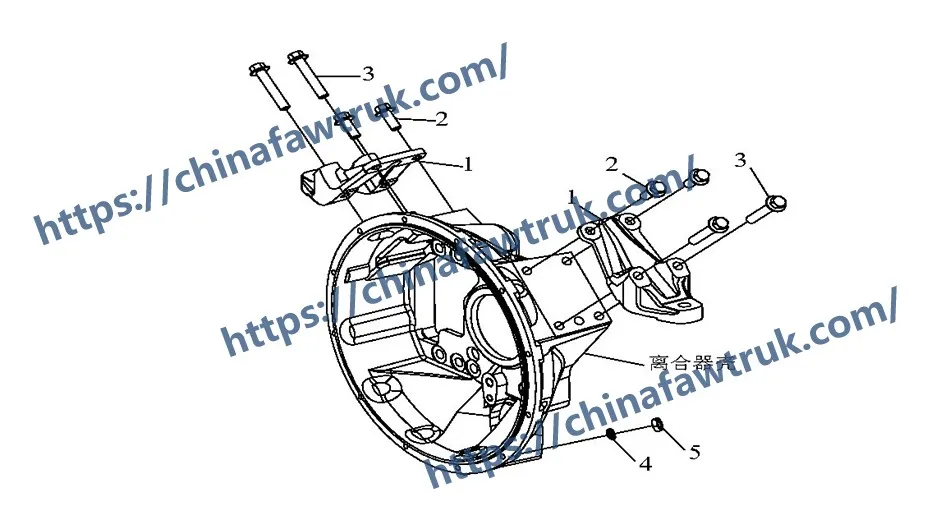

Bienvenidos a esta deconstrucción crítica de la Subchasis trasero del tren motriz FAW J6P, el conjunto que soporta la parte trasera de la caja de cambios de 10 velocidades CA10TA160M. Este sistema es esencial para el FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado. Esta guía deconstruye el 5 tipos de piezas que crean el completo Subchasis trasero del tren motriz FAW J6P sistema de montaje.

El Subchasis trasero del tren motriz FAW J6P es de alta resistencia, soporte amortiguador de vibraciones. Su lógica es doble.: debe soportar todo el peso estático de la transmisión, y debe “atrapar” el inmenso par de rotación del motor, todo ello aislando el chasis de las vibraciones de la transmisión.

Este grupo representa el “partes duras” del Subchasis trasero del tren motriz FAW J6P. Estos son los soportes de alta resistencia que conectan la carcasa rígida de la caja de cambios a los aisladores de goma flexibles..

1. Componente: ‘Soporte de caja de cambios izquierdo’ (1706051-71B) – Cantidad 2

Este (compensación 1) es el 'Soporte de soporte izquierdo de la caja de cambios'. La lista de piezas requiere dos, indicando que este es un diseño simétrico utilizado tanto para el “izquierda” y “bien” lados de la transmisión, aunque el nombre sólo especifica “izquierda”. Este soporte es el núcleo del Subchasis trasero del tren motriz FAW J6P.

El Lógica de carga estática es su primera función. Este es un enorme, soporte resistente, probablemente hecho de hierro fundido o acero forjado. Está diseñado para atornillarse de forma segura al costado de la carcasa de la caja de cambios principal. (utilizando pernos Comp 2/3). Es “brazo” luego se extiende hacia afuera para sentarse encima de un soporte de goma (el aislador). Este soporte soporta todo el peso estático de la mitad trasera de la transmisión de 10 velocidades., que pueden ser varios cientos de libras.

El Lógica de control de par es su segundo, función más crítica. Cuando el motor produce torque, trata de “girar” todo el tren motriz (motor y caja de cambios) en dirección opuesta a la rotación del cigüeñal. El Subchasis trasero del tren motriz FAW J6P es lo que “capturas” este giro.

Este soporte (compensación 1) actúa como una gran palanca, transfiriendo esta inmensa fuerza de rotación *hacia abajo* (en un lado) y *hacia arriba* (por el otro) en los soportes de goma. El “ala de gaviota” forma de esto Subchasis trasero del tren motriz FAW J6P El soporte está diseñado específicamente para proporcionar el brazo de palanca más rígido posible para contrarrestar esta fuerza de torsión., evitando que la caja de cambios se mueva y asegurando una entrega suave de potencia al eje de transmisión.

Aunque no se detalla explícitamente en esta lista de cinco partes, el 'Soporte de soporte’ (compensación 1) del Subchasis trasero del tren motriz FAW J6P es inútil sin su contraparte: el aislador de goma al que se atornilla. Este componente es el “bastidor auxiliar” sí mismo.

1. Componente: El aislador de caucho implícito (Montar)

El Subchasis trasero del tren motriz FAW J6P es un “bastidor auxiliar” porque incluye un gran caucho y acero “sándwich” montar. El 'soporte de soporte’ (compensación 1) pernos a la *parte superior* de este soporte de goma. La *parte inferior* de este soporte de goma luego se atornilla a un travesaño en el bastidor del chasis del camión. (usando hardware comp 4/5).

El Lógica de aislamiento es todo su propósito. Un motor diésel y una caja de cambios producen intensas, vibraciones de baja frecuencia. Si el 'Soporte de soporte’ (compensación 1) fueron atornillados directamente al chasis, Estas vibraciones se transferirían directamente al marco., creando un ensordecedor “zumbido” en la cabina y lo que lleva a un viaje difícil.

El Lógica de caucho vulcanizado así es como funciona. El bloque de goma es “vulcanizado” (unido con calor y presión) entre dos placas de acero. Esta goma es “sintonizado” a un durómetro específico (dureza) para absorber y “humedecer” Las frecuencias específicas del tren motriz.. Esto aísla el chasis., proporcionando un suave, viaje tranquilo para el conductor. Esta es la función más importante del subchasis trasero del tren motriz FSolarJ6P.

El Lógica a prueba de fallos es una característica clave del diseño. Estas monturas son “entrelazado.” Las placas de acero están diseñadas para que incluso si la goma falla por completo o se rompe, el 'Soporte de soporte’ (compensación 1) voluntad “atrapar” en la placa de acero inferior. Esto evita que la caja de cambios se caiga., permitiendo al conductor “cojeando a casa” sin peligro. Este mecanismo de seguridad es un sello distintivo de alta calidad. Subchasis trasero del tren motriz FAW J6P.

Este grupo contiene todo el hardware de alta resistencia necesario para ensamblar el Subchasis trasero del tren motriz FAW J6P. Este no es hardware estándar; Está diseñado específicamente para soportar vibraciones extremas y las inmensas “cortar” fuerzas de par del tren motriz.

1. El “Soporte a caja de cambios” Pernos (compensación 2, 3)

Este grupo incluye: «Perno de brida hexagonal’ (Q1851685T, Cantidad 4) y 'Perno de brida hexagonal’ (Q1851640T, Cantidad 4).

El Lógica de alta resistencia es primordial. Estos son de alto grado (P.EJ., 10.9) pernos que se enroscan directamente en los orificios roscados en el costado de la carcasa de la caja de cambios de aluminio o hierro. Son responsables de asegurar el 'Soporte de soporte'.’ (compensación 1) a la caja de cambios. Estos pernos están bajo constante esfuerzo cortante y de tracción debido a la Subchasis trasero del tren motriz FAW J6P.

El Lógica del perno de brida es un diseño resistente a las vibraciones. El “brida” es un incorporado, lavadora que no gira. Esta cara ancha distribuye la carga de sujeción y, más importante, proporciona una mucho mayor “cara de fricción” que resiste el aflojamiento por vibración mucho mejor que un perno y una arandela estándar. Esto es esencial para el Subchasis trasero del tren motriz FAW J6P.

2. El “Subchasis a chasis” Hardware (compensación 4, 5)

Este grupo incluye: 'arandela de resorte’ (Q40310, Cantidad 12) y «tuerca hexagonal’ (CQ34010, Cantidad 12).

El Lógica de sujeción principal es la función de este par. Es probable que este hardware se utilice en dos lugares.: 1) Para atornillar el 'soporte’ (compensación 1) *hacia abajo* sobre el perno superior del aislador de goma. 2) Para atornillar los *pernos inferiores* del aislador de goma a través del travesaño del chasis, asegurando toda la Subchasis trasero del tren motriz FAW J6P.

El Lógica antivibración es el trabajo de la 'arandela elástica'’ (compensación 4). En un entorno de alta vibración como un riel de chasis, una nuez (compensación 5) solo vibraría rápidamente y se soltaría. La 'arandela de resorte’ (compensación 4) es un endurecido, anillo partido que actúa como un resorte de alta tensión. Muerde tanto la tuerca como el marco., proporcionando constante, tensión activa que evita que la tuerca retroceda. Esta es la característica de seguridad más crítica del Subchasis trasero del tren motriz FAW J6Psistema de sujeción.

La siguiente tabla proporciona la información completa, desglose detallado de todos 5 tipos de componentes en el Subchasis trasero del tren motriz FAW J6P Montaje para FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1706051-71B | Soporte izquierdo caja de cambios | 2 |

| 2 | Q1851685T | Perno de brida hexagonal | 4 |

| 3 | Q1851640T | Perno de brida hexagonal | 4 |

| 4 | Q40310 | arandela de resorte | 12 |

| 5 | CQ34010 | Tuerca hexagonal | 12 |

Las especificaciones para el Subchasis trasero del tren motriz FAW J6P se definen por su función como alta resistencia, soporte amortiguador de vibraciones para la caja de cambios.

| Solicitud de vehículo | FAW Jiefang CA3250P66K2L1T1E 6×4 Camión de la basura |

| Grupo de sistema | Subchasis trasero del tren motriz FAW J6P (Montaje de caja de cambios) |

| Caja de cambios asociada | CA10ta160m (10-Velocidad) |

| Lógica primaria | Soporte de peso estático & Control de par rotacional |

| Lógica secundaria | Aislamiento de vibraciones del tren motriz (Mojadura) |

| Componente central | ‘Soporte de caja de cambios izquierdo’ (1706051-71B) – Cantidad 2 |

| Tipo de aislador | (Implícito) Soporte de caucho vulcanizado de alta resistencia |

| Sujetadores de soporte | «Perno de brida hexagonal’ (Q1851685T, Q1851640T) – 8 total |

| Sujetadores de chasis | 'arandela de resorte’ (Q40310) & «Tuerca hexagonal’ (CQ34010) – 12 conjuntos |

| Tipos de componentes totales | 5 |

| Sistema asociado | Travesaño del chasis del camión, Carcasa de la caja de cambios |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.