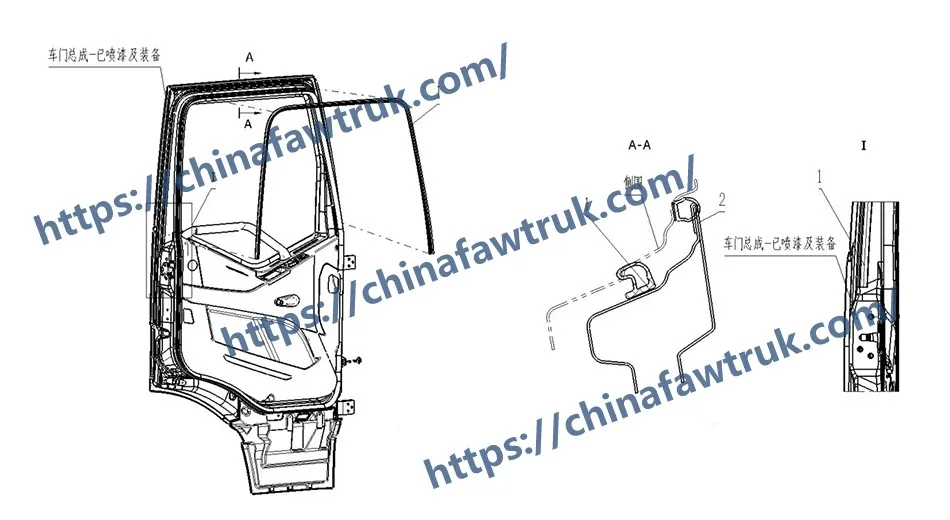

This technical guide provides a detailed deconstruction of the Front Door Secondary Seal assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This component is a crucial element in the vehicle’s “dual-seal” cab system. We will analyze the 2 critical parts, the seal itself and its mounting structure, to understand its role in weatherproofing.

The Front Door Secondary Seal, also known as a door-mounted seal, works in conjunction with the primary (body-mounted) seal. Its core logic is to create a “second line of defense” against the elements. Positioned on the door itself, it seals against the cab’s inner flange, creating an air-gap “dead zone.” This system is vital for preventing water, dust, and wind noise from entering the cab, especially in the extreme conditions faced by a CA3250P66K2L1T1E truck.

This first component is the functional core of the assembly. It is the part that actively creates the seal, and it is provided as two distinct parts for the left and right sides of the vehicle.

1. Component: ‘Left front door secondary seal’ (6107061-A01-C00) – Qty 1

2. Component: ‘Right front door secondary seal’ (6107062-A01-C00) – Qty 1

These two part numbers constitute the complete set of the Front Door Secondary Seal for the vehicle.

The Door-Mounted Logic is the first key principle. Unlike the primary seal (which is on the cab body), this Front Door Secondary Seal is attached directly to the perimeter of the door itself. This design is critical. It means the seal travels *with* the door, ensuring it is never scuffed, torn, or dislodged by personnel entering or exiting the cab.

The Profile and Material Logic is similar to other high-grade automotive seals. This component is made from a durable EPDM (Ethylene Propylene Diene Monomer) rubber. This material provides exceptional resistance to ozone, UV light, and temperature extremes, preventing it from cracking or hardening over time.

Its profile typically features a hollow “bulb” section. This is the part that compresses against the cab body’s inner metal flange when the door is closed. This compression creates the airtight and watertight barrier. The hollow design allows it to compensate for minor misalignments and to absorb the shock of a door slam, preventing a harsh “clang” and contributing to a quieter cab.

The Acoustic Damping Logic is the secondary, but equally important, function of the Front Door Secondary Seal. By creating a second, separate seal, it forms an “acoustic dead zone” in the channel between the primary seal and the secondary seal.

This trapped air gap is highly effective at disrupting and absorbing sound waves, particularly high-frequency wind noise. This “dual-seal” system is a hallmark of modern cab design, drastically reducing driver fatigue by creating a much quieter working environment. This is a key feature for the FAW Jiefang CA3250P66K2L1T1E.

Installation of the Front Door Secondary Seal (6107061-A01-C00 or 6107062-A01-C00) typically involves a series of pre-installed clips or a press-fit channel that engages with a groove or holes on the door’s inner structure.

This second group of components is not part of the seal itself, but represents the foundational structure to which the Front Door Secondary Seal mounts. A seal cannot function without a precise, rigid, and correctly shaped base.

1. Component: ‘Left front door welded assy’ (6100055-B27) – Qty 1

2. Component: ‘Right front door welded assy’ (6100060-B27) – Qty 1

This is the complete, welded-shut door shell for the FAW Jiefang CA3250P66K2L1T1E.

The Mounting Flange Logic is the most important concept here. The ‘Left front door welded assy’ (6100055-B27) is not just a flat panel. Its inner perimeter is stamped and formed into a precise channel or flange. This flange is the “track” that the Front Door Secondary Seal is designed to follow.

The shape, curvature, and angle of this flange are all critical. They are engineered in tandem with the seal’s profile to ensure that when the Front Door Secondary Seal is installed, it is held at the perfect angle and position. This ensures that the seal’s bulb compresses uniformly against the cab body.

The Rigidity Logic is also key. The ‘Right front door welded assy’ (6100060-B27) is a large, structurally rigid component. This rigidity is essential to the sealing system. The door must not flex or twist during vehicle operation, even on rough terrain.

If the door frame were to flex, it would create gaps between the Front Door Secondary Seal and the cab body, instantly compromising the seal and allowing noise, water, and dust to enter. The ‘welded assy’ provides the robust, stable platform necessary for the soft, flexible seal to do its job effectively.

Therefore, the Front Door Secondary Seal assembly is a system of two parts: the soft, flexible seal (Core 1) and the hard, rigid door structure (Core 2). They are listed together in this breakdown because one cannot be serviced or understood without the other.

A technician replacing a worn Front Door Secondary Seal must first inspect the door’s mounting flange (part of 6100055-B27 or 6100060-B27) for any damage, rust, or deformation. A bent flange will prevent even a brand new seal from functioning correctly.

The following table provides the complete, detailed breakdown of all 2 component types in the Front Door Secondary Seal assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 6107061-A01-C00 | Left front door secondary seal | 1 |

| 6107062-A01-C00 | Right front door secondary seal | 1 | |

| 2 | 6100055-B27 | Left front door welded assy | 1 |

| 6100060-B27 | Right front door welded assy | 1 |

The specifications for the Front Door Secondary Seal are defined by its role as the door-mounted part of a dual-seal weatherproofing system.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Front Door Secondary Seal |

| Associated System | Cab Door, Dual-Seal Weatherproofing |

| Primary Logic | Secondary Environmental Sealing (Water, Dust) |

| Secondary Logic | Acoustic Damping (Wind Noise Reduction) |

| Core Component (Seal) | ‘Left/Right front door secondary seal’ (6107061-A01-C00 / 6107062-A01-C00) |

| Core Component (Base) | ‘Left/Right front door welded assy’ (6100055-B27 / 6100060-B27) |

| Seal Material | EPDM (Ethylene Propylene Diene Monomer) Rubber |

| Seal Mount Location | On the door shell (Core 2) |

| Seal Contact Point | Inner cab body flange |

| Total Component Types | 2 (plus mirrored versions) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.