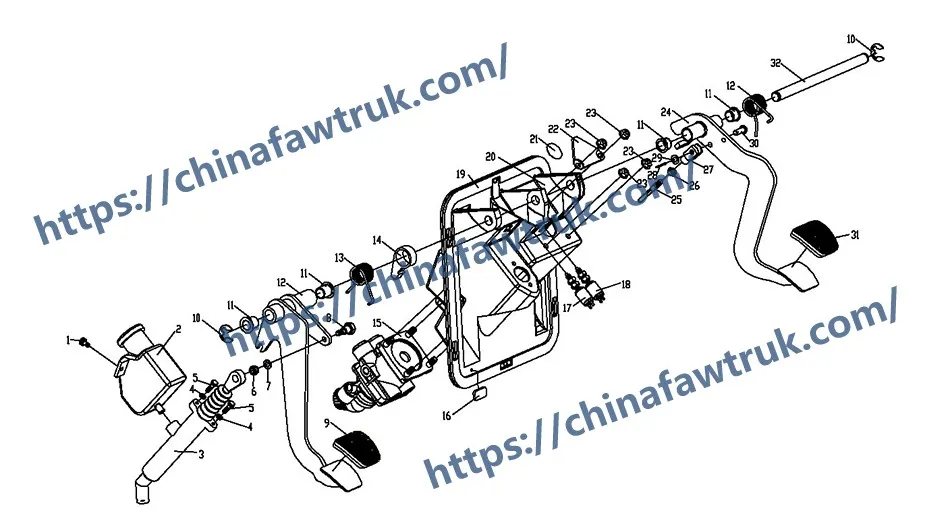

This is a focused technical deconstruction of the Clutch Pedal With Master Cylinder assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide details the 15 serviceable parts, sourced from the main pedal bracket BOM, that form the complete in-cab clutch control system.

The Clutch Pedal With Master Cylinder is a critical driver interface, responsible for disengaging the engine’s power from the transmission to allow for smooth gear shifts. On the FAW J6P, this is not a simple mechanical or hydraulic linkage; it is a sophisticated air-assisted hydraulic module. This Clutch Pedal With Master Cylinder assembly (part of the larger pedal bracket) uses pneumatic pressure from the truck’s air brake system to multiply the driver’s foot force, making the actuation of the heavy-duty clutch feel light and effortless. This deconstruction will analyze the key components of the Clutch Pedal With Master Cylinder, including the hydraulic oil cup, the air-over-hydraulic booster, the pedal itself, and the electronic interlock switch. A properly functioning Clutch Pedal With Master Cylinder is essential for driver comfort and protecting the transmission from damage.

This is the heart of the Clutch Pedal With Master Cylinder. This group of components creates the hydraulic pressure to actuate the clutch, and uses pneumatic air to provide the assist.

1. Component: ‘Clutch booster assy’ (1602110-76W) – Qty 1

This (Comp 3) is the primary component. It is a “master cylinder” integrated with a pneumatic booster. The Hydraulic Logic is that when the pedal is pressed, an internal piston pushes hydraulic fluid from the ‘Clutch oil cup’ (Comp 2) down a line to the clutch slave cylinder.

The Air-Assist Logic is what makes this part of the Clutch Pedal With Master Cylinder special. A small lever (Comp 14) opens an air valve inside this booster, which uses high-pressure air from the truck’s brake system to do most of the pushing. This reduces driver effort from hundreds of pounds to just a few.

2. Component: ‘Clutch oil cup assy’ (1602100-76W) – Qty 1

This (Comp 2) is the reservoir that holds the hydraulic (clutch/brake) fluid for the Clutch Pedal With Master Cylinder. It is mounted directly on top of the ‘Clutch booster’ (Comp 3) and must be kept sealed and filled to the correct level.

3. Component: ‘Arm – clutch booster air valve operating’ (1602027-50A) – Qty 1

This (Comp 14) is the small, precise lever that connects the ‘Clutch pedal’ (Comp 9) to the air valve on the ‘Clutch booster’ (Comp 3). Its geometry is key to the progressive feel of the Clutch Pedal With Master Cylinder.

This group of components forms the physical linkage of the Clutch Pedal With Master Cylinder, translating the driver’s foot movement into mechanical force for the booster.

1. Component: ‘Clutch pedal’ (1602037-50A) – Qty 1

This (Comp 9) is the main steel lever that the driver presses. It is a heavy-duty component designed to withstand millions of cycles. It is topped with a ‘Pad – clutch pedal’ (3504037-50A) for grip. This is the primary input for the Clutch Pedal With Master Cylinder.

2. Component: ‘Shaft – main’ (1602091-50A) & ‘Bushing’ (3504061-50A)

This (Comp 8, 11) is the pivot system. The ‘Shaft – main’ is the large-diameter pin that the clutch pedal and brake pedal both pivot on. The ‘Bushing – clutch pedal shaft’ (Comp 11, Qty 4) are pressed into the pedal to provide a smooth, low-friction, and quiet pivot point. Worn bushings are a common cause of a “sloppy” i>Clutch Pedal With Master Cylinder.

3. Component: ‘Return spring – clutch pedal’ (3504036-50A) – Qty 1

This (Comp 13) is a heavy-duty spring. Its Return Logic is to ensure the pedal returns firmly to the top position after being released. A weak or broken spring would cause the Clutch Pedal With Master Cylinder to feel vague and may not fully re-engage the clutch.

4. Component: ‘Clutch limit block’ (1602038-76W) – Qty 1

This (Comp 16) is the “stop block” or “bumper” that defines the upper travel limit of the pedal, preventing it from over-traveling and damaging the switch or linkage.

This group includes the main bracket that holds the Clutch Pedal With Master Cylinder to the cab and the electronic safety switches that integrate it with the vehicle’s ECU.

1. Component: ‘Clutch pedal bracket’ (1602020-76W) – Qty 1

This (Comp 12) is the main structural foundation for the Clutch Pedal With Master Cylinder. It is a heavy, stamped-steel bracket that bolts to the cab’s firewall. It must be extremely rigid to absorb the force of the driver’s leg and the booster’s air pressure without flexing.

2. Component: ‘Clutch switch assy’ (3754030-76W) – Qty 1

This (Comp 17) is an electronic switch activated by the clutch pedal. The Safety Interlock Logic is critical. This switch signals the ECU that the pedal is depressed, which performs two functions: 1) It allows the engine to be started (starter-motor safety), and 2) It informs the engine and cruise control that a gear shift is in process. This is a vital electronic part of the Clutch Pedal With Master Cylinder.

3. Component: Fastener Group (Q436150, CQ1740510, etc.)

This (Comp 4, 5, 6, 7, 10) is the hardware. This includes the ‘Hex head bolt with groove’ (Comp 5) and ‘Open lock washer’ (Comp 10) for securing the ‘Shaft – main’ (Comp 8), preventing it from “walking” laterally. The other fasteners secure the booster (Comp 3) to the bracket, ensuring a rigid, leak-free mount for the Clutch Pedal With Master Cylinder.

The following table provides a complete, detailed breakdown of all 15 component types related to the Clutch Pedal With Master Cylinder assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for any service of the Clutch Pedal With Master Cylinder module.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 2 | 1602100-76W | Clutch oil cup assy | 1 |

| 3 | 1602110-76W | Clutch booster assy | 1 |

| 4 | Q40305 | Spring washer | 2 |

| 5 | CQ1740510 | Hex head bolt with groove | 1 |

| 6 | CQ34008 | Hex nut | 1 |

| 7 | Q40308 | Spring washer | 1 |

| 8 | 1602091-50A | Shaft – main | 1 |

| 9 | 1602037-50A | Clutch pedal | 1 |

| 10 | Q436150 | Open lock washer | 2 |

| 11 | 3504061-50A | Bushing – clutch pedal shaft | 4 |

| 12 | 1602020-76W | Clutch pedal bracket | 1 |

| 13 | 3504036-50A | Return spring – clutch pedal | 1 |

| 14 | 1602027-50A | Arm – clutch booster air valve operating | 1 |

| 16 | 1602038-76W | Clutch limit block | 1 |

| 17 | 3754030-76W | Clutch switch assy | 1 |

The specifications for the Clutch Pedal With Master Cylinder assembly are defined by its dual-function, air-assisted hydraulic design, which is integrated into the main brake pedal bracket.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Clutch Pedal With Master Cylinder |

| System Type | Air-Assisted Hydraulic (Air-over-hydraulic) |

| Clutch Booster P/N | 1602110-76W |

| Clutch Fluid Reservoir P/N | 1602100-76W |

| Mounting Bracket P/N | 1602020-76W (Clutch) / 3504031-76W (Main) |

| Common Component | ‘Shaft – main’ (1602091-50A) for both pedals |

| Integrated Electronics | ‘Clutch switch assy’ (3754030-76W) (Safety Interlock) |

| Total Component Types | 15 |

| Associated System | Cab Controls / Clutch System. The Clutch Pedal With Master Cylinder is the core. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.