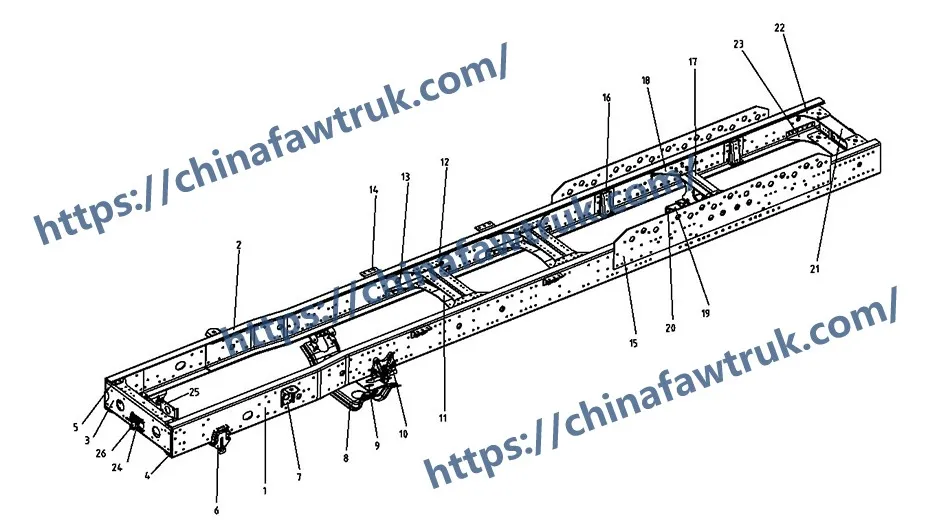

This is the definitive technical deconstruction of the FAW J6P Frame for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide provides a service-level breakdown of the 26 critical structural components, from the main side members to the complex crossmembers and suspension brackets that form the truck’s backbone.

The FAW J6P Frame is the single most important assembly of the vehicle, acting as the foundation for all other components. It is a heavy-duty, high-tensile steel ladder frame designed to withstand the extreme torsional, bending, and shock loads of a dump truck application. This deconstruction will analyze the main longitudinal beams, the transverse crossmembers that provide rigidity, and the multitude of brackets that attach the engine, cab, and suspension. A sound, fatigue-free FAW J6P Frame is non-negotiable for vehicle safety, load-bearing capacity, and the alignment of the entire drivetrain.

This group forms the two main ‘rails’ of the FAW J6P Frame. These are the primary load-bearing components that run the entire length of the truck.

1. Component: ‘Left side member assy’ (2801025A14BJ) – Qty 1

This (Comp 1) is the complete left-hand longitudinal beam. It is a single, C-channel or I-beam profile, precision-drilled to accept all crossmembers, suspension brackets, and the fuel tank. Its uncompromised structural integrity is essential for the fFAW J6P Frame.

2. Component: ‘Right side member assy’ (2801030A14BJ) – Qty 1

This (Comp 2) is the mirrored right-hand longitudinal beam. Together with the left member, it forms the ‘ladder’ of the FAW J6P Frame. Any twisting or cracking in these beams constitutes a critical chassis failure.

The crossmembers are the transverse beams that bolt or rivet between the two side members. They provide the critical torsional rigidity for the FAW J6P Frame, preventing it from twisting like a pretzel.

1. Component: ‘Front crossmember’ (2801072-70U) – Qty 1

This (Comp 3) is the front-most crossmember, which supports the bumper and radiator. It is a complex assembly that includes 8 welded square nuts for easy component mounting. It is attached via ‘Front crossmember left/right connecting plate’ (Comp 4, 5) and ‘Reinforcement plate-front crossmember’ (Comp 25). This front assembly is the face of the FAW J6P Frame.

2. Component: ‘Rear crossmember – front leaf spring’ (2901092-71BJ) – Qty 1

This (Comp 8) is a specialized crossmember located at the rear mounting point of the front leaf springs. It is a high-stress component that anchors the front suspension. It is supported by four ‘Reinforcement plates’ (Comp 9), highlighting the critical loads it handles for the FAW J6P Frame.

3. Component: ‘Third crossmember assy’ (2801110-71A) – Qty 2

This (Comp 11) is a mid-ship crossmember, often supporting the gearbox and driveshaft carrier bearing. Its position is critical for drivetrain alignment. The FAW J6P Frame uses these to maintain its shape.

4. Component: ‘Balance suspension crossmember’ (2801172-95A) – Qty 1

This (Comp 17) is the main crossmember for the rear tandem-axle suspension. It is a heavy-duty beam that anchors the suspension’s ‘trunnion’ or pivot point. It is connected via ‘Upper/Lower connecting plate’ (Comp 18, 19) and ‘Lower connecting shim’ (Comp 20). This is the load-bearing heart of the rear FAW J6P Frame.

5. Component: ‘Rear crossmember assy’ (2801180-487) – Qty 1

This (Comp 21) is the final crossmember at the very end of the FAW J6P Frame. It provides final rigidity and supports the rear tow hook and taillight assembly. It is connected via ‘Left/Right lower connecting plate’ (Comp 22, 23).

This group represents the numerous brackets bolted to the FAW J6P Frame that serve as the mounting points for the suspension, cab, and dump body.

1. Component: Front Suspension Brackets (Comp 6, 10)

This includes the ‘Front support – front leaf spring’ (Comp 6, 2902441-56A) and the ‘Rear support assy – front leaf spring’ (Comp 10, 2902450-71B). These two sets of brackets hold the entire front axle and leaf spring assembly. Their position on the FAW J6P Frame is critical for front-end alignment.

2. Component: ‘Upper support – front shock absorber’ (2905411-50A) – Qty 2

This (Comp 7) is the top mounting point for the front shock absorbers. It is bolted high on the FAW J6P Frame to provide the leverage needed for dampening.

3. Component: Rear Suspension Brackets (Comp 16)

This is the ‘Balance suspension pad left bracket assy’ (Comp 16, 2801035-487). These four brackets are the main mounting pads for the rear tandem-axle ‘trunnion’ assembly, working with the ‘Balance suspension crossmember’ (Comp 17) to support the entire rear load. These are some of the highest-stress points on the FAW J6P Frame.

4. Component: Body & Ancillary Brackets (Comp 14, 15, 24, 26)

This group includes ‘Sub-frame connecting gusset assy’ (Comp 14) for the dump body, ‘Truck body connecting plate’ (Comp 15), ‘Pin seat’ (Comp 24) for the cab tilt, and ‘Strap cotter pin assy’ (Comp 26). These smaller brackets are essential for attaching all other vehicle systems to the FAW J6P Frame.

The following table provides the complete, detailed breakdown of all 26 main component types in the FAW J6P Frame assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. Note that fasteners are listed within the component descriptions and are also available separately. This entire FAW J6P Frame is the foundation of the truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2801025A14BJ | Left side member assy | 1 |

| 2 | 2801030A14BJ | Right side member assy | 1 |

| 3 | 2801072-70U | Front crossmember (with 8 Q36412 welded square nuts) | 1 |

| 4 | 2801073-71U | Front crossmember left connecting plate | 1 |

| 5 | 2801074-71U | Front crossmember right connecting plate | 1 |

| 6 | 2902441-56A | Front support – front leaf spring | 2 |

| 7 | 2905411-50A | Upper support – front shock absorber | 2 |

| 8 | 2901092-71BJ | Rear crossmember – front leaf spring | 1 |

| 9 | 2801093-50A | Reinforcement plate – rear crossmember of front leaf spring | 4 |

| 10 | 2902450-71B | Rear support assy – front leaf spring | 2 |

| 11 | 2801110-71A | Third crossmember assy | 2 |

| 12 | 2801153-71B | Upper connecting plate – mid crossmember | 4 |

| 13 | 2801157-71B | Lower connecting plate – mid crossmember | 4 |

| 14 | 2801225-71A | Sub-frame connecting gusset assy | 4 |

| 15 | 2801211-50V | Truck body connecting plate | 2 |

| 16 | 2801035-487 | Balance suspension pad left bracket assy | 4 |

| 17 | 2801172-95A | Balance suspension crossmember | 1 |

| 18 | 2801173-242 | Upper connecting plate – balance suspension crossmember assy | 2 |

| 19 | 2801174-242 | Lower connecting plate – balance suspension crossmember assy | 2 |

| 20 | 2801177-242 | Lower connecting shim – balance suspension crossmember | 2 |

| 21 | 2801180-487 | Rear crossmember assy | 1 |

| 22 | 2801187-71B | Rear crossmember left lower connecting plate | 1 |

| 23 | 2801188-71B | Rear crossmember right lower connecting plate | 1 |

| 24 | 2806051-22A | Pin seat | 2 |

| 25 | 2801073-22A | Reinforcement plate – front crossmember | 1 |

| 26 | 2806015-22A | Strap cotter pin assy | 2 |

The specifications for the FAW J6P Frame are defined by its heavy-duty ladder design, engineered to support the CA3250P66K2L1T1E 6×4 dump truck’s maximum payload and withstand severe off-road conditions. The integrity of the FAW J6P Frame is the top priority for vehicle safety.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Frame |

| Primary Logic | Heavy-duty ladder frame, structural chassis backbone |

| Main Components | ‘Left side member assy’ (2801025A14BJ), ‘Right side member assy’ (2801030A14BJ) |

| Key Feature 1 | Full-length longitudinal C-channel rails |

| Key Feature 2 | Multiple high-strength transverse crossmembers for torsional rigidity |

| Front Suspension Mounts | ‘Front support’ (2902441-56A), ‘Rear support’ (2902450-71B) |

| Rear Suspension Mounts | ‘Balance suspension pad bracket’ (2801035-487), ‘Balance suspension crossmember’ (2801172-95A) |

| Total Main Component Types | 26 |

| Associated System | Vehicle Chassis. The FAW J6P Frame is the core of all systems. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.