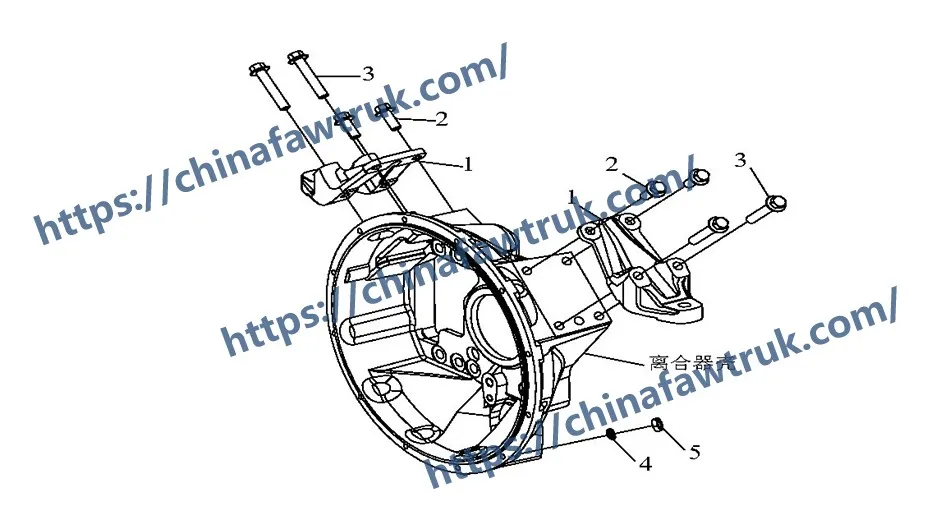

Welcome to this critical deconstruction of the FAW J6P Powertrain Rear Subframe, the assembly that supports the rear of the CA10TA160M 10-speed gearbox. This system is essential for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide deconstructs the 5 part types that create the complete FAW J6P Powertrain Rear Subframe mounting system.

The FAW J6P Powertrain Rear Subframe is a high-strength, vibration-damping mount. Its logic is twofold: it must bear the entire static weight of the transmission, and it must “catch” the immense rotational torque of the engine, all while isolating the chassis from drivetrain vibrations.

This group represents the “hard parts” of the FAW J6P Powertrain Rear Subframe. These are the high-strength brackets that connect the rigid gearbox housing to the flexible rubber isolators.

1. Component: ‘Gearbox left support bracket’ (1706051-71B) – Qty 2

This (Comp 1) is the ‘Gearbox left support bracket’. The parts list calls for two, indicating this is a symmetrical design used for both the “left” and “right” sides of the transmission, even though the name only specifies “left”. This bracket is the core of the FAW J6P Powertrain Rear Subframe.

The Static Load Logic is its first function. This is a massive, heavy-duty bracket, likely made of cast iron or forged steel. It is designed to bolt securely to the side of the main gearbox housing (using bolts Comp 2/3). Its “arm” then extends outwards to sit on top of a rubber mount (the isolator). This bracket bears the entire static weight of the rear half of the 10-speed transmission, which can be several hundred pounds.

The Torque Control Logic is its second, more critical function. When the engine produces torque, it tries to “twist” the entire powertrain (engine and gearbox) in the opposite direction of the crankshaft’s rotation. The FAW J6P Powertrain Rear Subframe is what “catches” this twist.

This bracket (Comp 1) acts as a large lever, transferring this immense rotational force *downward* (on one side) and *upward* (on the other) into the rubber mounts. The “gull-wing” shape of this FAW J6P Powertrain Rear Subframe bracket is specifically engineered to provide the most rigid possible lever arm to counteract this twisting force, preventing the gearbox from moving and ensuring smooth power delivery to the driveshaft.

While not explicitly itemized in this 5-part list, the ‘Support bracket’ (Comp 1) of the FAW J6P Powertrain Rear Subframe is useless without its counterpart: the rubber isolator it bolts to. This component is the “subframe” itself.

1. Component: The Implied Rubber Isolator (Mount)

The FAW J6P Powertrain Rear Subframe is a “subframe” because it includes a large rubber-and-steel “sandwich” mount. The ‘Support bracket’ (Comp 1) bolts to the *top* of this rubber mount. The *bottom* of this rubber mount then bolts to a crossmember on the truck’s chassis frame (using hardware Comp 4/5).

The Isolation Logic is its entire purpose. A diesel engine and gearbox produce intense, low-frequency vibrations. If the ‘Support bracket’ (Comp 1) were bolted directly to the chassis, these vibrations would be transferred directly into the frame, creating a deafening “drone” in the cab and leading to a rough ride.

The Vulcanized Rubber Logic is how it works. The rubber block is “vulcanized” (bonded with heat and pressure) between two steel plates. This rubber is “tuned” to a specific durometer (hardness) to absorb and “dampen” the specific frequencies of the powertrain. This isolates the chassis, providing a smooth, quiet ride for the driver. This is the most important function of the FSolarJ6P Powertrain Rear Subframe.

The Failsafe Logic is a key design feature. These mounts are “interlocking.” The steel plates are designed so that even if the rubber completely fails or tears, the ‘Support bracket’ (Comp 1) will “catch” on the lower steel plate. This prevents the gearbox from falling, allowing the driver to “limp home” safely. This failsafe is a hallmark of a high-quality FAW J6P Powertrain Rear Subframe.

This group contains all the high-tensile hardware required to assemble the FAW J6P Powertrain Rear Subframe. This is not standard hardware; it is specifically engineered to handle extreme vibration and the immense “shear” forces of powertrain torque.

1. The “Bracket-to-Gearbox” Bolts (Comp 2, 3)

This group includes: ‘Hexagon flange bolt’ (Q1851685T, Qty 4) and ‘Hexagon flange bolt’ (Q1851640T, Qty 4).

The High-Tensile Logic is paramount. These are high-grade (e.g., 10.9) bolts that thread directly into the tapped holes on the side of the aluminum or iron gearbox housing. They are responsible for securing the ‘Support bracket’ (Comp 1) to the gearbox. These bolts are under constant shear and tensile stress from the FAW J6P Powertrain Rear Subframe.

The Flange Bolt Logic is a vibration-resistant design. The “flange” is a built-in, non-spinning washer. This wide face distributes the clamping load and, more importantly, provides a much larger “friction face” that resists vibrational loosening far better than a standard bolt and washer. This is essential for the FAW J6P Powertrain Rear Subframe.

2. The “Subframe-to-Chassis” Hardware (Comp 4, 5)

This group includes: ‘Spring washer’ (Q40310, Qty 12) and ‘Hexagon nut’ (CQ34010, Qty 12).

The Main Clamping Logic is the function of this pair. This hardware is likely used in two places: 1) To bolt the ‘Support bracket’ (Comp 1) *down* onto the rubber isolator’s top stud. 2) To bolt the rubber isolator’s *bottom studs* through the chassis crossmember, securing the entire FAW J6P Powertrain Rear Subframe.

The Anti-Vibration Logic is the job of the ‘Spring washer’ (Comp 4). In a high-vibration environment like a chassis rail, a nut (Comp 5) alone would quickly vibrate loose. The ‘Spring washer’ (Comp 4) is a hardened, split ring that acts as a high-tension spring. It bites into both the nut and the frame, providing constant, active tension that prevents the nut from backing off. This is the most critical safety feature of the FAW J6P Powertrain Rear Subframe‘s fastener system.

The following table provides the complete, detailed breakdown of all 5 component types in the FAW J6P Powertrain Rear Subframe assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1706051-71B | Gearbox left support bracket | 2 |

| 2 | Q1851685T | Hexagon flange bolt | 4 |

| 3 | Q1851640T | Hexagon flange bolt | 4 |

| 4 | Q40310 | Spring washer | 12 |

| 5 | CQ34010 | Hexagon nut | 12 |

The specifications for the FAW J6P Powertrain Rear Subframe are defined by its function as a high-strength, vibration-damping mount for the gearbox.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Powertrain Rear Subframe (Gearbox Mount) |

| Associated Gearbox | CA10TA160M (10-Speed) |

| Primary Logic | Static Weight Support & Rotational Torque Control |

| Secondary Logic | Powertrain Vibration Isolation (Damping) |

| Core Component | ‘Gearbox left support bracket’ (1706051-71B) – Qty 2 |

| Isolator Type | (Implied) Heavy-Duty Vulcanized Rubber Mount |

| Bracket Fasteners | ‘Hexagon flange bolt’ (Q1851685T, Q1851640T) – 8 total |

| Chassis Fasteners | ‘Spring washer’ (Q40310) & ‘Hexagon nut’ (CQ34010) – 12 sets |

| Total Component Types | 5 |

| Associated System | Truck Chassis Crossmember, Gearbox Housing |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.