Welcome to this expert deconstruction of the FAW J6P Cylinder Block, the core component (P/N 1002014-36D) for the engine in the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is not just a part; it is the “bedrock” of the powertrain. The “logic” of the FAW J6P Cylinder Block is to be the structural chassis of the engine, containing combustion forces, housing the crankshaft, and providing the rigid backbone and all fluid passages.

The “design logic” of this specific FAW J6P Cylinder Block is centered on extreme durability and long-term serviceability. The engineering (as implied by related assemblies) points to a “wet liner” compatible design, meaning the cylinder walls themselves are replaceable. This is a critical feature for heavy-duty applications, allowing the engine to be rebuilt to “like-new” specifications multiple times, drastically extending its service life. A failure in the FAW J6P Cylinder Block is the most catastrophic engine failure possible, which is why its material science and manufacturing precision are paramount.

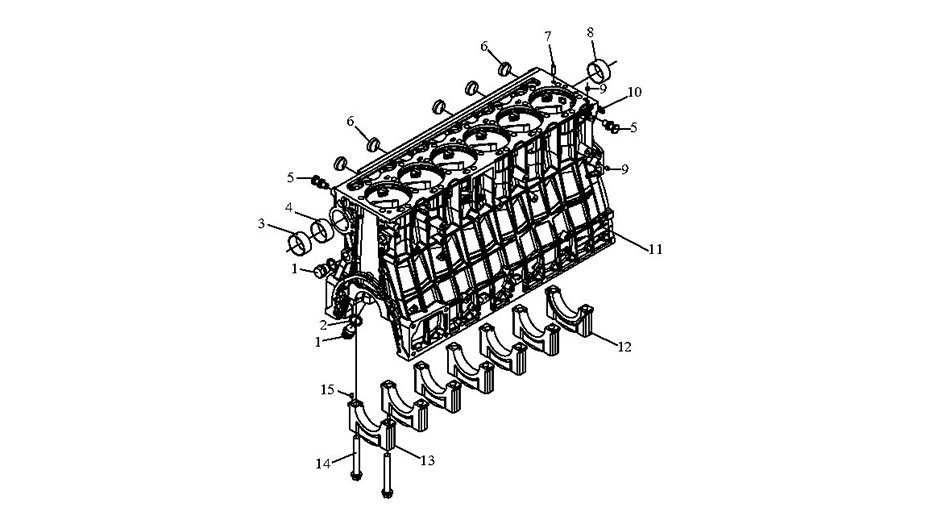

This technical guide is an essential resource for engine rebuilding specialists, heavy-duty technicians, and fleet parts managers. We will deconstruct the entire 15-component group associated with the bare FAW J6P Cylinder Block. We will analyze the “Crankshaft Support” logic (the caps, bolts, and pins), the “Camshaft Support” logic (the set of 11 bushes), and the critical “Foundry Sealing” logic (the various plugs and seals that make the casting watertight and oil-tight). This is the definitive analysis of the FAW J6P Cylinder Block core.

This entire component group is centered around the main casting itself. This is the heart of the engine’s structure and the core of the FAW J6P Cylinder Block.

1. Component: ‘Cylinder block’ (1002014-36D)

This is the primary component. The parts list shows a quantity of two (2), which may indicate a two-part (e.g., block and bedplate) design or different variants. Assuming this is the main block, its “foundry logic” is absolute strength. It is cast from a high-grade, high-nickel iron alloy, featuring extensive internal ribbing and thick “main webs” (the sections that hold the crankshaft) to prevent the block from flexing or “walking” under the immense load of diesel combustion.

Its “fluid logic” is equally complex. It contains a massive “water jacket” (the internal passages for coolant) that surrounds the cylinder bores, and a separate, high-pressure “oil gallery” system that is drilled through the block to deliver oil to the crankshaft main bearings and up to the cylinder head. The “machining logic” of this FAW J6P Cylinder Block is its most precise feature: the top “deck” is milled perfectly flat to seal the head gasket, and the “main bores” are line-bored to a tolerance of ten-thousandths of an inch to ensure the crankshaft spins perfectly.

This group of components has one logic: to secure the engine’s crankshaft in the FAW J6P Cylinder Block with perfect alignment and immense clamping force.

1. Components: ‘Main bearing cap’ (1002011-36D) & ‘Rear main bearing cap’ (1002012-36D)

This is the “containment logic.” The crankshaft rests in the “saddles” of the FAW J6P Cylinder Block. These ‘Main bearing caps’ (Comp 13) are the other half that “caps” the crankshaft, creating a perfect circle for the bearings. Their “precision logic” is critical: these caps are machined *while bolted to the block* (line-boring). This means Cap 1 *only* fits in Position 1, Cap 2 in Position 2, etc., and they must face the correct direction. The ‘Rear main bearing cap’ (Comp 12) is special, as it is larger and also holds the main “thrust” bearings that control the crankshaft’s front-to-back movement (end play).

2. Components: ‘Main bearing bolt’ (1002013-36D) & ‘Dowel pin’ (Q5210612)

This is the “alignment and clamping” logic. The ‘Dowel pins’ (Comp 15), with a quantity of 14 (two for each of the 7 main caps), provide the “alignment logic.” Their job is to ensure the cap is perfectly aligned side-to-side *before* the bolts are tightened. The ‘Main bearing bolts’ (Comp 14), also 14, provide the “clamping logic.” These are not standard bolts; they are high-tensile, torque-to-yield (TTY) fasteners. Their logic is to stretch slightly when torqued, acting like a high-tension spring to provide a massive, consistent clamping force that prevents the caps from “walking” under load. This is a safety-critical part of the FAW J6P Cylinder Block assembly.

This engine is a “cam-in-block” (OHV) design, meaning the camshaft is mounted inside the FAW J6P Cylinder Block. This group’s logic is to support that rotating shaft.

Components: ‘Front/Intermediate/Rear camshaft bush’ (1006024A29D, 1006028A29D, 1006029A29D)

This is the “sacrificial bearing” logic. The camshaft doesn’t ride directly on the cast iron of the block. Instead, it rides on these “bushes” (or “cam bearings”). These are soft-metal sleeves that are “pressed” into the bores of the FAW J6P Cylinder Block. Their “logic” is twofold: 1) They provide a soft, low-friction surface for the camshaft to rotate on. 2) They are “sacrificial.” If oil starvation occurs, the soft bush will be destroyed, saving the much more expensive camshaft and FAW J6P Cylinder Block from damage. The parts list calls for 1 ‘Front’ (Comp 3), 5 ‘Intermediate’ (Comp 4), and 5 ‘Rear’ (Comp 8) bushes, totaling 11, which suggests a complex or multi-shaft system (e.g., camshaft and balance shaft) are all supported within the FAW J6P Cylinder Block.

This final group’s “logic” is to seal all the “holes” left from manufacturing and to provide service access. A bare FAW J6P Cylinder Block casting is full of passages for sand (from casting), coolant, and oil (from drilling).

1. The “Coolant Jacket” Logic: ‘Bowl plug’ (Q72240, Q72224)

These are commonly called “freeze plugs.” Their “logic” is to seal the large, circular holes (Comp 6, 10) in the side of the FAW J6P Cylinder Block that were necessary to remove the internal sand core after casting. They are simply hammered in to create a watertight seal for the coolant jacket.

2. The “Oil Gallery” Logic: ‘Hex head plug’ (Q/WC3413-1994) & ‘Copper gasket’ (Q/WC3403-1994)

The main oil gallery is drilled from the front to the rear of the block. This “plug” (Comp 1) is a high-pressure, threaded bolt. Its “logic” is to permanently seal the end of that oil gallery. The ‘Copper gasket’ (Comp 2) is a soft, one-time-use seal that crushes to create a perfect, high-pressure, oil-tight seal. Additional plugs like ‘Oil seal plug’ (Comp 7) and ‘Plug-cylinder block’ (Comp 9) serve similar functions for other fluid passages, ensuring the integrity of the FAW J6P Cylinder Block.

3. The “Utility” Logic: ‘Lifting eyebolt’ (1002021-29D)

This component’s “logic” is purely for service. The FAW J6P Cylinder Block (and the full engine) is incredibly heavy. These two ‘Lifting eyebolts’ (Comp 5) are load-rated, high-strength steel bolts that are screwed into the block. They provide a safe and balanced attachment point for an engine crane or hoist, allowing for safe removal and installation of the FAW J6P Cylinder Block.

The following table provides the complete, detailed breakdown of all 15 component types associated with the bare FAW J6P Cylinder Block for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | Q/WC3413-1994 | Hexagon head screw M27x2 | 2 |

| 2 | Q/WC3403-1994 | Copper gasket 27×38 | 2 |

| 3 | 1006024A29D | Front camshaft bush | 1 |

| 4 | 1006028A29D | Intermediate camshaft bush | 5 |

| 5 | 1002021-29D | Lifting eyebolt | 2 |

| 6 | Q72240 | Bowl plug | 2 |

| 7 | 1002022-36D | Oil seal plug-cylinder block | 2 |

| 8 | 1006029A29D | Rear camshaft bush | 5 |

| 9 | 1002023-36D | Plug-cylinder block | 1 |

| 10 | Q72224 | Bowl plug | 1 |

| 11 | 1002014-36D | Cylinder block | 2 |

| 12 | 1002012-36D | Rear main bearing cap | 1 |

| 13 | 1002011-36D | Main bearing cap | 1 |

| 14 | 1002013-36D | Main bearing bolt | 14 |

| 15 | Q5210612 | Dowel pin | 14 |

The specifications for the bare FAW J6P Cylinder Block are defined by its function as the structural foundation of the engine.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Cylinder Block (Bare, Serviceable) |

| Main Component Part No. | 1002014-36D (‘Cylinder block’) |

| Block Design Type | Cam-in-Block (OHV), “Wet Liner” Compatible Design |

| Primary Logic | Structural Integrity, Crankshaft/Camshaft Alignment, Fluid Management |

| Material | High-Strength Cast Iron Alloy |

| Crankshaft Support System | ‘Main bearing cap’ (1002011-36D, 1002012-36D) |

| Crankshaft Clamping System | ‘Main bearing bolt’ (1002013-36D) – Qty 14 (TTY Type) |

| Crankshaft Alignment | ‘Dowel pin’ (Q5210612) – Qty 14 |

| Camshaft Support System | ‘Camshaft bush’ (1006024/28/29A29D) – Qty 11 total |

| Sealing Logic (Foundry) | ‘Bowl plug’ (Q72240, Q72224) for coolant jacket |

| Sealing Logic (Fluid Gallery) | ‘Hex head plug’ (Q/WC3413-1994) w/ ‘Copper gasket’ (Q/WC3403-1994) |

| Service Logic | ‘Lifting eyebolt’ (1002021-29D) for safe handling |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.