مرحبا بكم في هذا التفكيك الخبير لل كتلة اسطوانة FAW J6P, المكون الأساسي (P/N 1002014-36D) for the engine in the FAW Jiefang CA3250P66K2L1T1E 6×4 تفريغ الشاحنة. This is not just a part; هذا هو “bedrock” of the powertrain. ال “منطق” التابع كتلة اسطوانة FAW J6P is to be the structural chassis of the engine, containing combustion forces, housing the crankshaft, and providing the rigid backbone and all fluid passages.

ال “منطق التصميم” من هذا محددة كتلة اسطوانة FAW J6P is centered on extreme durability and long-term serviceability. The engineering (as implied by related assemblies) points to a “بطانة مبللة” compatible design, meaning the cylinder walls themselves are replaceable. This is a critical feature for heavy-duty applications, allowing the engine to be rebuilt to “مثل الجديد” specifications multiple times, drastically extending its service life. فشل في كتلة اسطوانة FAW J6P is the most catastrophic engine failure possible, which is why its material science and manufacturing precision are paramount.

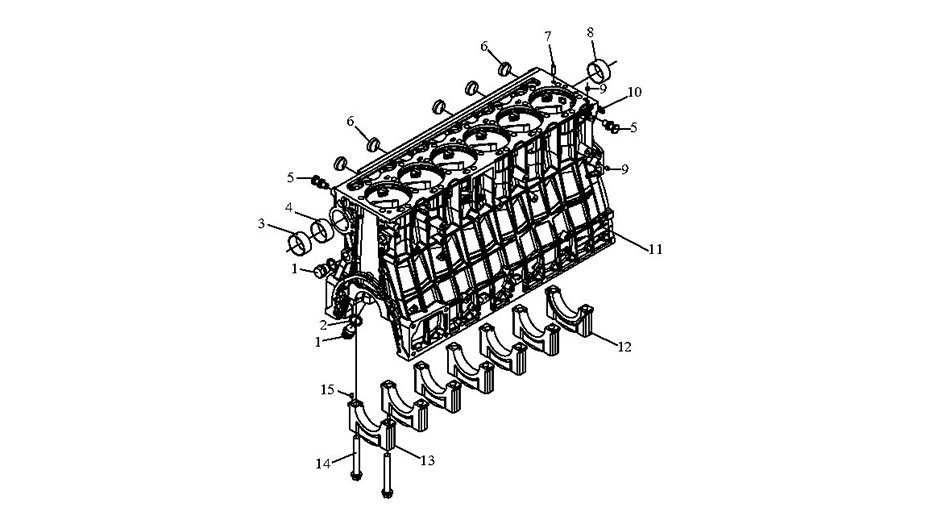

This technical guide is an essential resource for engine rebuilding specialists, heavy-duty technicians, ومديري قطع غيار الأسطول. We will deconstruct the entire 15-component group associated with the bare كتلة اسطوانة FAW J6P. سنقوم بتحليل “Crankshaft Support” منطق (the caps, البراغي, ودبابيس), ال “Camshaft Support” منطق (the set of 11 bushes), والحرجة “Foundry Sealing” منطق (the various plugs and seals that make the casting watertight and oil-tight). This is the definitive analysis of the كتلة اسطوانة FAW J6P جوهر.

This entire component group is centered around the main casting itself. This is the heart of the engine’s structure and the core of the كتلة اسطوانة FAW J6P.

1. عنصر: ‘Cylinder block’ (1002014-36د)

This is the primary component. The parts list shows a quantity of two (2), which may indicate a two-part (على سبيل المثال, block and bedplate) design or different variants. Assuming this is the main block, إنه “foundry logic” is absolute strength. It is cast from a high-grade, high-nickel iron alloy, featuring extensive internal ribbing and thick “الشبكات الرئيسية” (the sections that hold the crankshaft) to prevent the block from flexing or “المشي” under the immense load of diesel combustion.

إنه “منطق السوائل” is equally complex. It contains a massive “سترة المياه” (the internal passages for coolant) that surrounds the cylinder bores, and a separate, الضغط العالي “oil gallery” system that is drilled through the block to deliver oil to the crankshaft main bearings and up to the cylinder head. ال “machining logic” من هذا كتلة اسطوانة FAW J6P is its most precise feature: the top “ظهر السفينة” is milled perfectly flat to seal the head gasket, و “main bores” are line-bored to a tolerance of ten-thousandths of an inch to ensure the crankshaft spins perfectly.

This group of components has one logic: to secure the engine’s crankshaft in the كتلة اسطوانة FAW J6P with perfect alignment and immense clamping force.

1. عناصر: ‘Main bearing cap’ (1002011-36د) & ‘Rear main bearing cap’ (1002012-36د)

هذا هو “منطق الاحتواء” The crankshaft rests in the “السروج” التابع كتلة اسطوانة FAW J6P. These ‘Main bearing caps’ (شركات 13) are the other half that “caps” the crankshaft, creating a perfect circle for the bearings. هُم “precision logic” أمر بالغ الأهمية: these caps are machined *while bolted to the block* (line-boring). This means Cap 1 *only* fits in Position 1, كاب 2 in Position 2, إلخ., and they must face the correct direction. The ‘Rear main bearing cap’ (شركات 12) is special, as it is larger and also holds the main “التوجه” bearings that control the crankshaft’s front-to-back movement (نهاية اللعب).

2. عناصر: ‘Main bearing bolt’ (1002013-36د) & ‘Dowel pin’ (Q5210612)

هذا هو “alignment and clamping” منطق. The ‘Dowel pins’ (شركات 15), with a quantity of 14 (two for each of the 7 main caps), provide the “منطق المحاذاة” Their job is to ensure the cap is perfectly aligned side-to-side *before* the bolts are tightened. The ‘Main bearing bolts’ (شركات 14), also 14, provide the “منطق المشبك.” هذه ليست مسامير قياسية; they are high-tensile, عزم الدوران إلى العائد (TTY) السحابات. Their logic is to stretch slightly when torqued, acting like a high-tension spring to provide a massive, consistent clamping force that prevents the caps from “المشي” under load. This is a safety-critical part of the كتلة اسطوانة FAW J6P حَشد.

هذا المحرك هو “cam-in-block” (OHV) تصميم, meaning the camshaft is mounted inside the كتلة اسطوانة FAW J6P. This group’s logic is to support that rotating shaft.

عناصر: ‘Front/Intermediate/Rear camshaft bush’ (1006024A29D, 1006028A29D, 1006029A29D)

هذا هو “sacrificial bearing” منطق. The camshaft doesn’t ride directly on the cast iron of the block. بدلاً من, it rides on these “bushes” (أو “cam bearings”). These are soft-metal sleeves that are “الضغط” into the bores of the كتلة اسطوانة FAW J6P. هُم “منطق” ذو شقين: 1) They provide a soft, low-friction surface for the camshaft to rotate on. 2) هم “ذبيحة.” If oil starvation occurs, the soft bush will be destroyed, saving the much more expensive camshaft and كتلة اسطوانة FAW J6P from damage. قائمة الأجزاء تدعو إلى 1 'أمام’ (شركات 3), 5 ‘Intermediate’ (شركات 4), و 5 'مؤخرة’ (شركات 8) bushes, المجموع 11, which suggests a complex or multi-shaft system (على سبيل المثال, camshaft and balance shaft) are all supported within the كتلة اسطوانة FAW J6P.

هذه المجموعة النهائية “منطق” is to seal all the “holes” left from manufacturing and to provide service access. A bare كتلة اسطوانة FAW J6P casting is full of passages for sand (from casting), سائل التبريد, and oil (from drilling).

1. ال “Coolant Jacket” منطق: ‘Bowl plug’ (Q72240, Q72224)

These are commonly called “freeze plugs.” هُم “منطق” is to seal the large, circular holes (شركات 6, 10) in the side of the كتلة اسطوانة FAW J6P that were necessary to remove the internal sand core after casting. They are simply hammered in to create a watertight seal for the coolant jacket.

2. ال “Oil Gallery” منطق: ‘Hex head plug’ (Q/WC3413-1994) & ‘Copper gasket’ (س/WC3403-1994)

The main oil gallery is drilled from the front to the rear of the block. هذا “سدادة” (شركات 1) is a high-pressure, threaded bolt. إنه “منطق” is to permanently seal the end of that oil gallery. The ‘Copper gasket’ (شركات 2) is a soft, one-time-use seal that crushes to create a perfect, الضغط العالي, oil-tight seal. Additional plugs like ‘Oil seal plug’ (شركات 7) and ‘Plug-cylinder block’ (شركات 9) serve similar functions for other fluid passages, ضمان سلامة كتلة اسطوانة FAW J6P.

3. ال “جدوى” منطق: ‘Lifting eyebolt’ (1002021-29د)

هذا المكون “منطق” is purely for service. ال كتلة اسطوانة FAW J6P (and the full engine) is incredibly heavy. These two ‘Lifting eyebolts’ (شركات 5) are load-rated, high-strength steel bolts that are screwed into the block. They provide a safe and balanced attachment point for an engine crane or hoist, allowing for safe removal and installation of the كتلة اسطوانة FAW J6P.

الجدول التالي يوفر كامل, تفصيل مفصل للجميع 15 component types associated with the bare كتلة اسطوانة FAW J6P لفاو جيفانغ CA3250P66K2L1T1E 6×4 تفريغ الشاحنة.

| علامة | الجزء لا. | جزء اسم | كمية |

|---|---|---|---|

| 1 | Q/WC3413-1994 | Hexagon head screw M27x2 | 2 |

| 2 | س/WC3403-1994 | Copper gasket 27×38 | 2 |

| 3 | 1006024A29D | Front camshaft bush | 1 |

| 4 | 1006028A29D | بوش عمود الحدبات المتوسطة | 5 |

| 5 | 1002021-29د | Lifting eyebolt | 2 |

| 6 | Q72240 | قابس وعاء | 2 |

| 7 | 1002022-36د | Oil seal plug-cylinder block | 2 |

| 8 | 1006029A29D | بوش عمود الحدبات الخلفي | 5 |

| 9 | 1002023-36د | Plug-cylinder block | 1 |

| 10 | Q72224 | قابس وعاء | 1 |

| 11 | 1002014-36د | حاجز الاسطوانة | 2 |

| 12 | 1002012-36د | Rear main bearing cap | 1 |

| 13 | 1002011-36د | غطاء المحمل الرئيسي | 1 |

| 14 | 1002013-36د | الترباس الحامل الرئيسي | 14 |

| 15 | Q5210612 | دبوس وتد | 14 |

The specifications for the bare كتلة اسطوانة FAW J6P are defined by its function as the structural foundation of the engine.

| تطبيق المركبة | فاو جيفانغ CA3250P66K2L1T1E 6×4 شاحنة قلابة |

| مجموعة النظام | كتلة اسطوانة FAW J6P (Bare, صالحة للخدمة) |

| Main Component Part No. | 1002014-36د (‘Cylinder block’) |

| Block Design Type | Cam-in-Block (OHV), “Wet Liner” Compatible Design |

| المنطق الأساسي | السلامة الهيكلية, Crankshaft/Camshaft Alignment, إدارة السوائل |

| مادة | سبائك الحديد الزهر عالية القوة |

| Crankshaft Support System | ‘Main bearing cap’ (1002011-36د, 1002012-36د) |

| Crankshaft Clamping System | ‘Main bearing bolt’ (1002013-36د) – الكمية 14 (TTY Type) |

| Crankshaft Alignment | ‘Dowel pin’ (Q5210612) – الكمية 14 |

| Camshaft Support System | ‘Camshaft bush’ (1006024/28/29A29D) – الكمية 11 المجموع |

| منطق الختم (مسبك) | ‘Bowl plug’ (Q72240, Q72224) for coolant jacket |

| منطق الختم (Fluid Gallery) | ‘Hex head plug’ (Q/WC3413-1994) w/ ‘Copper gasket’ (س/WC3403-1994) |

| منطق الخدمة | ‘Lifting eyebolt’ (1002021-29د) for safe handling |

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.