Welcome to this definitive technical analysis of the FAW J6P Cylinder Head Assembly (Main Assy P/N 1003010A59D), the “control room” for the engine powering the FAW Jiefang CA3250P66K2L1T1E 6×4 diesel dump truck. This is the single most complex casting in the powertrain. The “logic” of the FAW J6P Cylinder Head Assembly is threefold: to seal combustion, manage all engine “breathing” (airflow), and house the entire valvetrain and engine brake system.

The “thermal and fluid logic” of this FAW J6P Cylinder Head Assembly is critical to its survival. It manages the hottest, most violent part of the combustion process. To do this, it is engineered with an intricate, cast-in “water jacket” (coolant passages) that are designed to flow the maximum amount of coolant around the exhaust valve seats and injector bores, preventing the head from warping or cracking. Simultaneously, its “airflow logic” is defined by its intake and exhaust ports, which are not simple holes; they are shaped to induce “swirl” and “tumble” in the intake air, a key factor in achieving an efficient, powerful, and clean diesel combustion. A proper-functioning FAW J6P Cylinder Head Assembly is paramount to engine performance.

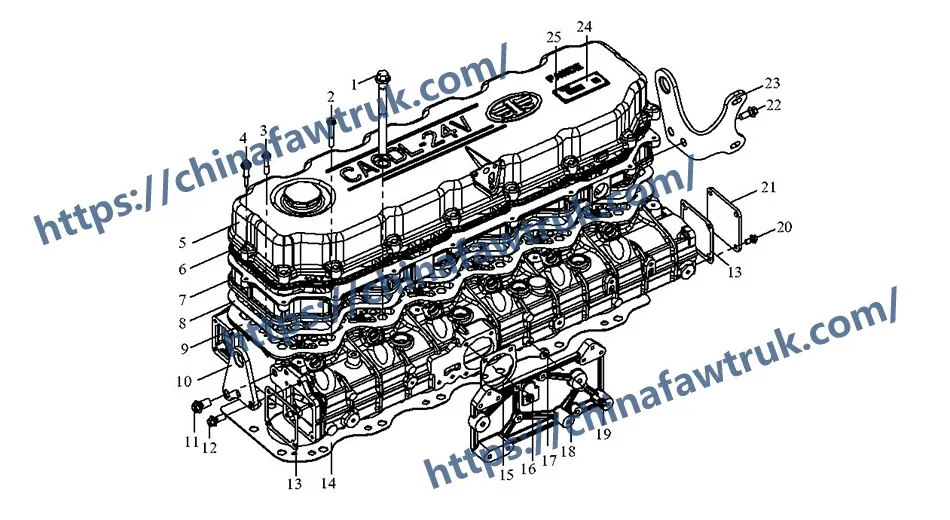

This expert guide is an essential resource for engine rebuilders, fleet technicians, and parts specialists. We will deconstruct the entire 20-component group, breaking it down into four primary “logic” systems: the “Main Structural Assembly” (the head itself), the “Valvetrain Housing” Logic (the covers and engine brake frame), the critical “Sealing & Interface” Logic (the gaskets), and the “Critical Fastener & Utility” Logic that holds the entire FAW J6P Cylinder Head Assembly system together.

This group contains the functional core of the entire FAW J6P Cylinder Head Assembly. All other parts exist to support, seal, or attach to these.

1. Component: ‘Cylinder head assy’ (1003010A59D)

This (Comp 9) is the main casting, the functional heart of the FAW J6P Cylinder Head Assembly. Its “structural logic” is to be the “upper half” of the engine, creating the top of the combustion chamber. Its “deck” (the bottom, flat surface) is machined to a mirror-flat, precise finish to create a perfect seal against the ‘Cylinder head gasket’ (Comp 14) and the FAW Cylinder Block. Its “airflow logic” is its most complex feature, containing the intake and exhaust ports for all six cylinders. These passages are engineered to optimize the flow of air and exhaust, which is a primary factor in the engine’s horsepower and emissions. A failure (like a crack or warp) in this single component is a catastrophic failure for the entire engine, making this FAW J6P Cylinder Head Assembly a zero-compromise part.

2. Component: ‘Cylinder head cover lower frame assy’ (1003060A48D)

This (Comp 7) is the most specialized part of this FAW J6P Cylinder Head Assembly. The list specifies this “lower frame” is for models “with engine brake.” This is the “Engine Brake Logic.” A “Jake Brake” system works by using high-pressure oil to open the exhaust valves at the wrong time (on the compression stroke), turning the engine into an air compressor to slow the truck. This ‘Lower frame’ is not just a spacer; it is a complex “manifold” that houses the high-pressure oil solenoids and passages for this system. The “without engine brake” variant (1003060-621-000Z) is a simple, non-functional frame.

This group’s “logic” is to cover and seal the top of the FAW J6P Cylinder Head Assembly, protecting the valvetrain and sealing the oil inside.

1. Components: ‘Cylinder head cover assy’ (1003030B29D) & ‘Seal strip’ (1003041B29D)

This is the “valve cover.” Its “sealing logic” is simple but crucial: it must keep the engine’s lubricating oil *in* and keep dirt, water, and debris *out*. The ‘Cylinder head cover’ (Comp 5) acts as the primary “roof.” The ‘Seal strip’ (Comp 6) is the engineered rubber gasket that fits in a groove on the cover or frame. It is designed to be compressed to a specific

degree to create a perfect, oil-tight seal that can also withstand the engine’s vibrations.

2. Component: ‘Composite seal gasket’ (1003047-29D)

This gasket (Comp 8) is the “high-pressure seal” for the engine brake system. It provides the “interface logic” between the ‘Lower frame’ (Comp 7) and the main ‘Cylinder head assy’ (Comp 9). It must seal both the low-pressure oil “splash” from the valvetrain *and* the high-pressure oil that is fed into the engine brake manifold. A failure here would cause the engine brake to stop working and lead to an internal or external oil leak. This seal is vital to the FAW J6P Cylinder Head Assembly‘s advanced functions.

This group contains the single most critical “sealing” component in the entire engine, as well as the gaskets that interface with the air manifold.

1. Component: ‘Cylinder head gasket assy’ (1003020-36D)

This (Comp 14) is the single most important “logic” seal in the engine. Its “multi-seal logic” is extreme: it must simultaneously perform three non-negotiable sealing tasks. 1) **Combustion Sealing:** It uses “fire rings” to contain 2500+ PSI of combustion pressure and heat. 2) **Coolant Sealing:** It seals the water jacket, preventing high-pressure coolant from leaking out or (worse) into the cylinders. 3) **Oil Sealing:** It seals the high-pressure oil gallery that feeds the FAW J6P Cylinder Head Assembly, preventing it from leaking into the coolant or out of the engine. This is a Multi-Layer Steel (MLS) gasket, and its failure is catastrophic.

2. Components: ‘Intake’ Gaskets & Covers (Comp 13, 15, 17, 18)

This is the “air interface logic.” The ‘Gasket-intake pipe’ (Comp 13) provides the seal for the main air connection *to* the FAW J6P Cylinder Head Assembly‘s intake ports. The ‘Intake manifold right cover’ (Comp 18) and its associated gaskets (Comp 15 & 17 – note the two different part numbers, suggesting a design change or different materials) have a “service logic.” They likely block off an access port on the intake side of the head, which might be used for sensors or different manifold configurations on other models.

This final group’s “logic” is to provide the immense clamping force and service points required to make the FAW J6P Cylinder Head Assembly function.

1. Component: ‘Bolt-Cylinder head’ (1003046-36D)

This is the “Critical Clamping Logic.” The list calls for 26 of these (Comp 1). These are *not* standard bolts. They are “Torque-to-Yield” (TTY) bolts. Their “logic” is that they are designed to be torqued to a specific point where they *permanently stretch*, acting like a massive, high-tension spring. This is the only way to provide the enormous and perfectly *even* clamping force needed to hold the FAW J6P Cylinder Head Assembly flat against the block. They are *single-use by definition* and MUST be replaced every time the head is serviced.

2. Component: ‘Damping bolt assy’ (1003110-29D)

This is the “Valvetrain Fastener Logic.” With a quantity of 17 (Comp 4), these are almost certainly the bolts that secure the rocker arm shafts or individual rocker pedestals to the main FAW J6P Cylinder Head Assembly casting. The “damping” description (or “Combination bolt” alternative) suggests they are engineered to provide a secure fit while possibly reducing valvetrain “clatter” and improving NVH.

3. Components: ‘Front lifting eye’ (1003058-29D) & ‘Bolt’ (1003057-29D)

This is the “Service Logic.” The FAW J6P Cylinder Head Assembly is extremely heavy and must be lifted perfectly straight up to avoid damaging the block. The ‘Lifting eye’ (Comp 10) and its specific ‘Bolt’ (Comp 11) provide a load-rated, engineered attachment point for an engine crane, ensuring safe and proper service. The other flange bolts (Comp 2, 3, 12, 16, 19, 20) are the “auxiliary logic,” used to secure all the covers, frames, and brackets to the FAW J6P Cylinder Head Assembly.

The following table provides the complete, detailed breakdown of all 20 component types identified in this FAW J6P Cylinder Head Assembly group for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1003046-36D | Bolt-Cylinder head | 26 |

| 2 | Q1860855 | Hexagon flange bolt-large series | 13 |

| 3 | Q1860840 | Hexagon flange bolt-large series | 1 |

| 4 | 1003110-29D (1003090-600-000Z) | Damping bolt assy (Combination bolt) | 17 |

| 5 | 1003030B29D (1003030-600-000Z) | Cylinder head cover assy | 1 |

| 6 | 1003041B29D (1003041-600-000Z) | Seal strip-cylinder cover (Gasket-upper cylinder head cover) | 1 |

| 7 | 1003060A48D (1003060-621-000Z) | Cylinder head cover lower frame assy (with engine brake) (without engine brake) | 1 |

| 8 | 1003047-29D (1003047-600-000Z) | Composite seal gasket-cylinder head cover lower frame (Gasket-cylinder cover) | 1 |

| 9 | 1003010A59D (1003010-630-000Z) | Cylinder head assy | 1 |

| 10 | 1003058-29D (1003058A29D) | Front lifting eye-cylinder head | 1 |

| 11 | 1003057-29D | Bolt-front lifting eye | 1 |

| 12 | Q1841025 | Hexagon flange bolt | 2 |

| 13 | 1008019-29D (1008019-29DZ) | Gasket-intake pipe (Fully interchangeable) | 3 |

| 14 | 1003020-36D | Cylinder head gasket assy | 1 |

| 15 | 1008013-29D (1008013-29DZ) | Gasket-intake manifold right cover (Fully interchangeable) | 1 |

| 16 | Q1840825 | Hexagon flange bolt | 2 |

| 17 | 1008013-48D (1008013-621-0000) | Gasket-intake manifold right cover | 1 |

| 18 | 1008012-48D (1008012B621-0000) | Intake manifold right cover | 1 |

| 19 | Q1840830 | Hexagon flange bolt | 2 |

| 20 | Q1840816 | Hexagon flange bolt | 4 |

The specifications for the FAW J6P Cylinder Head Assembly are defined by its function as the “control room” of the engine, managing air, fuel, and heat.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Cylinder Head Assembly |

| Main Assembly Part No. | 1003010A59D (‘Cylinder head assy’) |

| Primary Logic | Airflow Management (Ports), Combustion Sealing, Valvetrain Housing |

| Key Feature | Housing for Engine Brake (‘Lower frame assy’ – 1003060A48D) |

| Critical Gasket | ‘Cylinder head gasket assy’ (1003020-36D), Multi-Layer Steel (MLS) |

| Critical Fasteners | ‘Bolt-Cylinder head’ (1003046-36D) – Qty 26 |

| Fastener Type | Torque-to-Yield (TTY) – Single-Use, Must Be Replaced |

| Valvetrain Fasteners | ‘Damping bolt assy’ (1003110-29D) – Qty 17 |

| Service Utility | ‘Front lifting eye’ (1003058-29D) for safe removal |

| Associated System | Complete FAW J6P Cylinder Head Assembly |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.