Bienvenidos a este análisis técnico definitivo del Conjunto de culata FAW J6P (Conjunto principal P/N 1003010A59D), el “control room” for the engine powering the FAW Jiefang CA3250P66K2L1T1E 6×4 camión volquete diésel. This is the single most complex casting in the powertrain. El “lógica” del Conjunto de culata FAW J6P es triple: to seal combustion, manage all engine “respiración” (airflow), and house the entire valvetrain and engine brake system.

El “thermal and fluid logic” de esto Conjunto de culata FAW J6P is critical to its survival. It manages the hottest, most violent part of the combustion process. To do this, it is engineered with an intricate, cast-in “water jacket” (coolant passages) that are designed to flow the maximum amount of coolant around the exhaust valve seats and injector bores, preventing the head from warping or cracking. Simultáneamente, es “airflow logic” is defined by its intake and exhaust ports, which are not simple holes; they are shaped to induce “swirl” y “tumble” in the intake air, a key factor in achieving an efficient, powerful, and clean diesel combustion. A proper-functioning Conjunto de culata FAW J6P is paramount to engine performance.

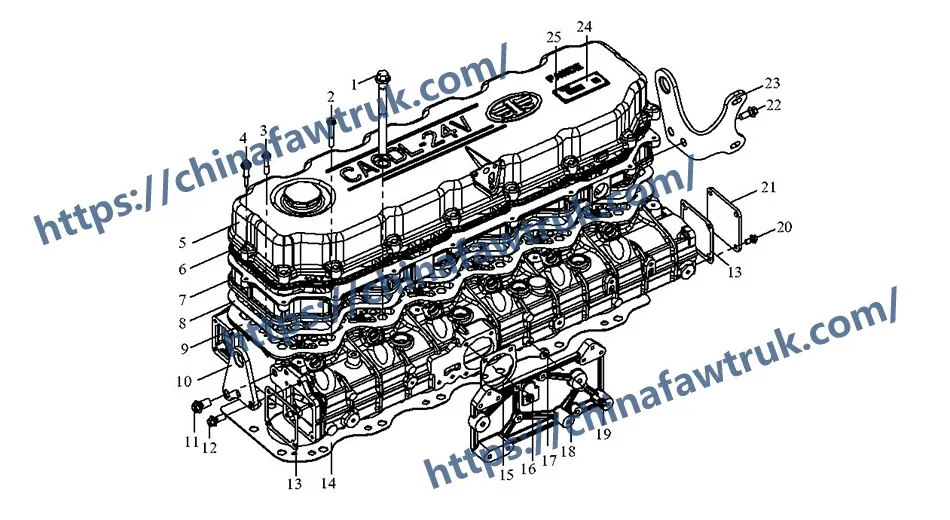

Esta guía de expertos es un recurso esencial para los reconstructores de motores., tecnicos de flota, y especialistas en repuestos. We will deconstruct the entire 20-component group, breaking it down into four primary “lógica” sistemas: el “Main Structural Assembly” (the head itself), el “Valvetrain Housing” Lógica (the covers and engine brake frame), el critico “Sellando & Interfaz” Lógica (las juntas), y el “Sujetador crítico & Utility” Logic that holds the entire Conjunto de culata FAW J6P system together.

This group contains the functional core of the entire Conjunto de culata FAW J6P. All other parts exist to support, sello, or attach to these.

1. Componente: ‘Cylinder head assy’ (1003010A59D)

Este (compensación 9) es el casting principal, the functional heart of the Conjunto de culata FAW J6P. Es “lógica estructural” es ser el “upper half” del motor, creating the top of the combustion chamber. Es “cubierta” (the bottom, flat surface) is machined to a mirror-flat, precise finish to create a perfect seal against the ‘Cylinder head gasket’ (compensación 14) and the FAW Cylinder Block. Es “airflow logic” is its most complex feature, containing the intake and exhaust ports for all six cylinders. These passages are engineered to optimize the flow of air and exhaust, which is a primary factor in the engine’s horsepower and emissions. un fracaso (like a crack or warp) in this single component is a catastrophic failure for the entire engine, haciendo esto Conjunto de culata FAW J6P a zero-compromise part.

2. Componente: ‘Cylinder head cover lower frame assy’ (1003060A48D)

Este (compensación 7) is the most specialized part of this Conjunto de culata FAW J6P. The list specifies this “lower frame” is for models “with engine brake.” Este es el “Engine Brake Logic.” A “jake freno” system works by using high-pressure oil to open the exhaust valves at the wrong time (on the compression stroke), turning the engine into an air compressor to slow the truck. This ‘Lower frame’ is not just a spacer; es un complejo “colector” that houses the high-pressure oil solenoids and passages for this system. El “without engine brake” variant (1003060-621-000z) es un simple, non-functional frame.

el de este grupo “lógica” is to cover and seal the top of the Conjunto de culata FAW J6P, protecting the valvetrain and sealing the oil inside.

1. Componentes: ‘Cylinder head cover assy’ (1003030B29D) & ‘Seal strip’ (1003041B29D)

Este es el “valve cover.” Es “lógica de sellado” is simple but crucial: it must keep the engine’s lubricating oil *in* and keep dirt, agua, y escombros *fuera*. The ‘Cylinder head cover’ (compensación 5) acts as the primary “roof.” The ‘Seal strip’ (compensación 6) is the engineered rubber gasket that fits in a groove on the cover or frame. It is designed to be compressed to a specific

degree to create a perfect, oil-tight seal that can also withstand the engine’s vibrations.

2. Componente: ‘Composite seal gasket’ (1003047-29D)

Esta junta (compensación 8) es el “sello de alta presión” for the engine brake system. Proporciona la “interface logic” between the ‘Lower frame’ (compensación 7) and the main ‘Cylinder head assy’ (compensación 9). It must seal both the low-pressure oil “chapoteo” from the valvetrain *and* the high-pressure oil that is fed into the engine brake manifold. A failure here would cause the engine brake to stop working and lead to an internal or external oil leak. This seal is vital to the Conjunto de culata FAW J6P‘s advanced functions.

This group contains the single most critical “caza de focas” component in the entire engine, as well as the gaskets that interface with the air manifold.

1. Componente: ‘Cylinder head gasket assy’ (1003020-36D)

Este (compensación 14) is the single most important “lógica” seal in the engine. Es “multi-seal logic” is extreme: it must simultaneously perform three non-negotiable sealing tasks. 1) **Combustion Sealing:** se utiliza “fire rings” to contain 2500+ PSI of combustion pressure and heat. 2) **Coolant Sealing:** It seals the water jacket, preventing high-pressure coolant from leaking out or (peor) into the cylinders. 3) **Oil Sealing:** It seals the high-pressure oil gallery that feeds the Conjunto de culata FAW J6P, preventing it from leaking into the coolant or out of the engine. This is a Multi-Layer Steel (MLS) empaquetadora, and its failure is catastrophic.

2. Componentes: ‘Intake’ Juntas & Cubiertas (compensación 13, 15, 17, 18)

Este es el “air interface logic.” The ‘Gasket-intake pipe’ (compensación 13) provides the seal for the main air connection *to* the Conjunto de culata FAW J6P‘s intake ports. The ‘Intake manifold right cover’ (compensación 18) and its associated gaskets (compensación 15 & 17 – note the two different part numbers, suggesting a design change or different materials) have a “lógica de servicio.” They likely block off an access port on the intake side of the head, which might be used for sensors or different manifold configurations on other models.

Este grupo final “lógica” is to provide the immense clamping force and service points required to make the Conjunto de culata FAW J6P función.

1. Componente: ‘Bolt-Cylinder head’ (1003046-36D)

Este es el “Critical Clamping Logic.” La lista pide 26 de estos (compensación 1). These are *not* standard bolts. Ellos son “Par-a-rendimiento” (TTY) perno. Su “lógica” es que están diseñados para ser apretados hasta un punto específico donde *se estiran permanentemente*, acting like a massive, high-tension spring. This is the only way to provide the enormous and perfectly *even* clamping force needed to hold the Conjunto de culata FAW J6P flat against the block. They are *single-use by definition* and MUST be replaced every time the head is serviced.

2. Componente: ‘Damping bolt assy’ (1003110-29D)

Este es el “Valvetrain Fastener Logic.” With a quantity of 17 (compensación 4), these are almost certainly the bolts that secure the rocker arm shafts or individual rocker pedestals to the main Conjunto de culata FAW J6P casting. El “mojadura” descripción (o “Perno combinado” alternative) suggests they are engineered to provide a secure fit while possibly reducing valvetrain “clatter” and improving NVH.

3. Componentes: ‘Front lifting eye’ (1003058-29D) & ‘Bolt’ (1003057-29D)

Este es el “Service Logic.” El Conjunto de culata FAW J6P is extremely heavy and must be lifted perfectly straight up to avoid damaging the block. The ‘Lifting eye’ (compensación 10) and its specific ‘Bolt’ (compensación 11) provide a load-rated, engineered attachment point for an engine crane, ensuring safe and proper service. The other flange bolts (compensación 2, 3, 12, 16, 19, 20) son los “auxiliary logic,” used to secure all the covers, marcos, and brackets to the Conjunto de culata FAW J6P.

La siguiente tabla proporciona la información completa, desglose detallado de todos 20 tipos de componentes identificados en este Conjunto de culata FAW J6P group for the FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1003046-36D | Bolt-Cylinder head | 26 |

| 2 | Q1860855 | Hexagon flange bolt-large series | 13 |

| 3 | Q1860840 | Hexagon flange bolt-large series | 1 |

| 4 | 1003110-29D (1003090-600-000z) | Damping bolt assy (Perno combinado) | 17 |

| 5 | 1003030B29D (1003030-600-000z) | Cylinder head cover assy | 1 |

| 6 | 1003041B29D (1003041-600-000z) | Seal strip-cylinder cover (Gasket-upper cylinder head cover) | 1 |

| 7 | 1003060A48D (1003060-621-000z) | Cylinder head cover lower frame assy (with engine brake) (without engine brake) | 1 |

| 8 | 1003047-29D (1003047-600-000z) | Composite seal gasket-cylinder head cover lower frame (Gasket-cylinder cover) | 1 |

| 9 | 1003010A59D (1003010-630-000z) | Cylinder head assy | 1 |

| 10 | 1003058-29D (1003058A29D) | Front lifting eye-cylinder head | 1 |

| 11 | 1003057-29D | Bolt-front lifting eye | 1 |

| 12 | Q1841025 | Perno de brida hexagonal | 2 |

| 13 | 1008019-29D (1008019-29DZ) | Junta-tubo de admisión (Totalmente intercambiable) | 3 |

| 14 | 1003020-36D | Cylinder head gasket assy | 1 |

| 15 | 1008013-29D (1008013-29DZ) | Gasket-intake manifold right cover (Totalmente intercambiable) | 1 |

| 16 | Q1840825 | Perno de brida hexagonal | 2 |

| 17 | 1008013-48D (1008013-621-0000) | Gasket-intake manifold right cover | 1 |

| 18 | 1008012-48D (1008012B621-0000) | Intake manifold right cover | 1 |

| 19 | Q1840830 | Perno de brida hexagonal | 2 |

| 20 | Q1840816 | Perno de brida hexagonal | 4 |

Las especificaciones para el Conjunto de culata FAW J6P se definen por su función como “control room” del motor, managing air, combustible, y calor.

| Solicitud de vehículo | FAW Jiefang CA3250P66K2L1T1E 6×4 Camión de la basura |

| Grupo de sistema | Conjunto de culata FAW J6P |

| Número de pieza del conjunto principal. | 1003010A59D (‘Cylinder head assy’) |

| Lógica primaria | Airflow Management (Ports), Combustion Sealing, Valvetrain Housing |

| Característica clave | Housing for Engine Brake (‘Lower frame assy’ – 1003060A48D) |

| Critical Gasket | ‘Cylinder head gasket assy’ (1003020-36D), Acero multicapa (MLS) |

| Sujetadores críticos | ‘Bolt-Cylinder head’ (1003046-36D) – Cantidad 26 |

| Tipo de sujetador | Par-a-rendimiento (TTY) – De un solo uso, Debe ser reemplazado |

| Valvetrain Fasteners | ‘Damping bolt assy’ (1003110-29D) – Cantidad 17 |

| Service Utility | ‘Front lifting eye’ (1003058-29D) for safe removal |

| Sistema asociado | Completo Conjunto de culata FAW J6P |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.