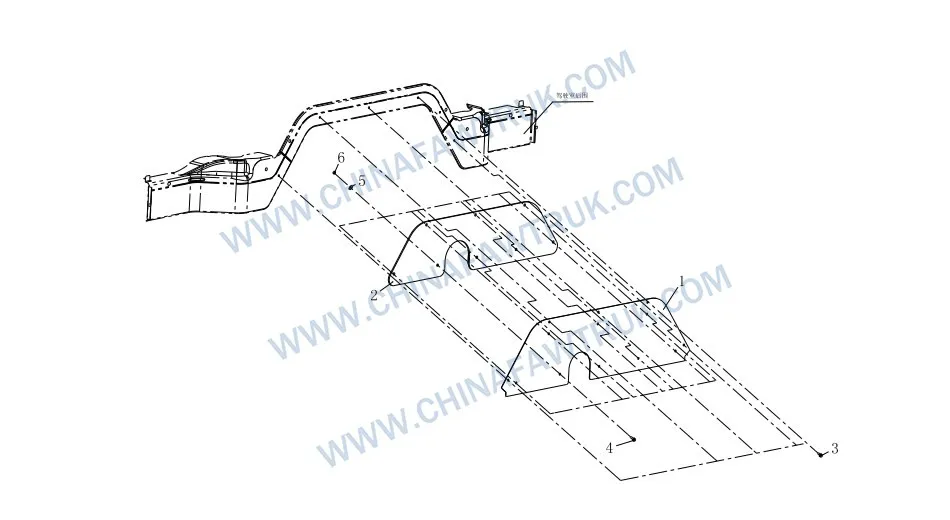

Panneau d'isolation phonique du moteur arrière: Déploiement 28 Composants stratégiques pour l'isolation acoustique

Le Panneau d'isolation phonique du moteur arrière logic assembly is a sophisticated noise-suppression system engineered specifically for the Camion-benne FAW CA3250P66K24L1TE5Z. Operating in the harsh acoustic environment of heavy mining, this assembly serves as the primary barrier between the high-decibel diesel engine and the vehicle’s chassis structure. By effectively absorbing mechanical noise and deflecting thermal energy, le Panneau d'isolation phonique du moteur arrière enhances operator comfort and reduces environmental noise pollution, s'assurer que le Panneau d'isolation phonique du moteur arrière remains a critical compliance factor for modern fleet operations in the Russian Arctic.

Panneau d'isolation phonique du moteur arrière

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

5103511-55R. |

Engine Rear Sound Insulation Panel Fixing Plate |

1 |

| 2 |

5103513-55R. |

Engine Rear Sound Insulation Panel |

1 |

| 3 |

CQ1460616 |

Boulon combiné |

5 |

| 4 |

CQ1460620 |

Boulon combiné |

7 |

| 5 |

Q40206 |

Grande laveuse |

7 |

| 6 |

CQ34006 |

Écrou hexagonal |

7 |

Acoustic Damping and Material Science

The primary functional element of this assembly is the Engine Rear Sound Insulation Panel (Partie no. 5103513-55R.). This component is not a simple sheet of plastic; it is a multi-layered acoustic barrier designed specifically for the frequency range of a heavy-duty diesel engine. The material composition, denoted by the “55R.” suffixe, indicates a specialized rubber-polymer blend that maintains its density and damping characteristics even in the sub-zero temperatures of the Russian winter. Standard insulation materials often become brittle and lose their acoustic properties when frozen, mais le Panneau d'isolation phonique du moteur arrière remains flexible, effectively absorbing structural vibrations.

La conception du Engine Rear Sound Insulation Panel incorporates a textured surface that breaks up sound waves, preventing them from reflecting off the panel and amplifying engine noise. This technology is crucial for reducing the overall noise signature of the dump truck, which is a key requirement for operating near residential areas or sensitive environmental zones. By trapping airborne noise within its cellular structure, le Panneau d'isolation phonique du moteur arrière significantly lowers the decibel levels reaching the cabin. This reduction provided by the Panneau d'isolation phonique du moteur arrière directly contributes to reduced driver fatigue during long shifts.

En outre, le Panneau d'isolation phonique du moteur arrière acts as a thermal shield. Located in close proximity to the rear of the engine block, it is exposed to significant radiant heat. The 55R material is engineered to resist thermal degradation, preventing warping or melting. Simultanément, le Panneau d'isolation phonique du moteur arrière protects the chassis components behind it from the intense heat soak of the engine, ensuring that hydraulic lines and wiring harnesses located in the vicinity are not subjected to dangerous temperature spikes, preserving the longevity of the vehicle’s auxiliary systems through the robust design of the Panneau d'isolation phonique du moteur arrière.

Soutien structurel: The Fixing Plate

The soft acoustic material of the insulation panel requires a rigid skeleton to maintain its shape and position within the Panneau d'isolation phonique du moteur arrière assemblée. This is the function of the Engine Rear Sound Insulation Panel Fixing Plate (Partie no. 5103511-55R.). This metal component acts as the structural backbone of the assembly, providing a series of rigid mounting points for the flexible insulation material. Sans le Engine Rear Sound Insulation Panel Fixing Plate, the insulation panel would sag under its own weight or deform under the pressure of aerodynamic drag and engine vibration, rendant le Panneau d'isolation phonique du moteur arrière inefficace.

L'interface entre le Engine Rear Sound Insulation Panel et le Engine Rear Sound Insulation Panel Fixing Plate est critique. The plate is stamped with stiffening ribs to prevent resonance. If the fixing plate were to vibrate at the same frequency as the engine, it would become a noise source itself. FAW engineers have tuned the mass and stiffness of the Engine Rear Sound Insulation Panel Fixing Plate to ensure it remains inert, acting purely as a support structure. Le “55R.” specification on the plate likely refers to a matching corrosion-resistant coating that protects the metal from the harsh saline environment, Assurer le Panneau d'isolation phonique du moteur arrière resists rust.

Un bon alignement du Engine Rear Sound Insulation Panel Fixing Plate is essential for the effective sealing of the engine bay. Gaps between the panel and the engine block allow noise to escape and dirt to ingress. The fixing plate ensures that the Panneau d'isolation phonique du moteur arrière is held firmly against its sealing surfaces, creating a continuous acoustic barrier. This structural integrity is vital for maintaining the “quiet zone” around the chassis, demonstrating the importance of this metal component in the overall Panneau d'isolation phonique du moteur arrière assemblée.

Logique de fixation: Boulons combinés

Securing the assembly requires a robust fastening strategy, utilizing two variants of the Boulon combiné: Partie no. CQ1460616 (Quantité 5) et numéro de pièce. CQ1460620 (Quantité 7). Le terme “Boulon combiné” is significant in the context of the Panneau d'isolation phonique du moteur arrière. It indicates that these fasteners come with pre-assembled captive washers—typically a flat washer and a split lock washer. This integration ensures that the critical locking mechanism is never omitted during assembly, which is vital for preventing the Panneau d'isolation phonique du moteur arrière de la vibration lâche.

The difference in length between the two Boulon combiné variantes (16mm vs. 20mm) caters to the varying thickness of the mounting stack-up at different points on the chassis. Using the shorter bolt in a deep hole would result in insufficient thread engagement, while using the longer bolt in a shallow hole could lead to bottoming out. The specific selection of these Boulon combiné units ensures that the Engine Rear Sound Insulation Panel Fixing Plate is clamped with the correct force across all twelve mounting points, distributing the load evenly across the Panneau d'isolation phonique du moteur arrière structure.

The surface treatment of the Boulon combiné is also a key durability factor for the Panneau d'isolation phonique du moteur arrière. Located at the rear of the engine, these fasteners are exposed to road spray, chaleur, et sels de déglaçage corrosifs. High-quality anti-corrosion coatings, such as zinc-flake, are essential to prevent the bolts from seizing into the nuts. Seized bolts turn a simple panel replacement into a time-consuming repair involving drilling and tapping. The use of these specialized bolts ensures that the Panneau d'isolation phonique du moteur arrière remains serviceable throughout the life of the truck.

Répartition de la charge: Washers and Nuts

To protect the soft material of the Engine Rear Sound Insulation Panel from damage during installation, l'assemblée utilise le Grande laveuse (Partie no. Q40206). Seven of these units are strategically placed at mounting points where the bolt head would otherwise bear directly on the insulation material of the Panneau d'isolation phonique du moteur arrière. Le Grande laveuse increases the surface area over which the clamping force is applied, preventing the bolt from crushing the acoustic polymer or pulling through it entirely. This is essential for maintaining the structural integrity of the Panneau d'isolation phonique du moteur arrière.

Securing the bolts are seven units of the Écrou hexagonal (Partie no. CQ34006). These nuts work in tandem with the Boulon combiné pour créer un environnement sécurisé, vibration-resistant connection for the Panneau d'isolation phonique du moteur arrière. In many locations on the chassis, threaded holes are not available, necessitating the use of a through-bolt and nut configuration. Le Écrou hexagonal provides a reliable anchor point, permettant à la Engine Rear Sound Insulation Panel Fixing Plate to be sandwiched tightly against the chassis rails, Assurer le Panneau d'isolation phonique du moteur arrière does not shift during operation.

L'interaction entre le Grande laveuse, le Boulon combiné, et le Écrou hexagonal creates a fastening system that accommodates thermal expansion within the Panneau d'isolation phonique du moteur arrière système. As the engine heats up and the plastic panel expands, the large surface area of the washer allows for slight movement without inducing stress cracks. This flexibility is a hallmark of the Panneau d'isolation phonique du moteur arrière conception, ensuring that the assembly can withstand the extreme temperature cycles of the Russian climate without failing, thus maintaining the effectiveness of the Panneau d'isolation phonique du moteur arrière.

Conclusion: A Silent Guardian

Le Panneau d'isolation phonique du moteur arrière is a critical component for the operational refinement of the FAW CA3250 dump truck. By integrating the acoustic damping properties of the Engine Rear Sound Insulation Panel with the structural rigidity of the Engine Rear Sound Insulation Panel Fixing Plate, FAW delivers a solution that effectively mitigates noise and heat. The robust fastening system, comprenant le Boulon combiné, Grande laveuse, et Écrou hexagonal, ensures that the protection offered by the Panneau d'isolation phonique du moteur arrière remains in place despite the brutal vibration of mining operations.

Pour les équipes de maintenance, assurer l'intégrité du Panneau d'isolation phonique du moteur arrière est vital. A missing panel or loose Boulon combiné can lead to increased cabin noise and potential heat damage to chassis components. By using genuine parts and adhering to the correct assembly logic, operators can ensure that their fleet continues to operate quietly and efficiently. Le Panneau d'isolation phonique du moteur arrière stands as a testament to the detailed engineering required to meet the high standards of modern heavy-duty logistics in the Russian North.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.