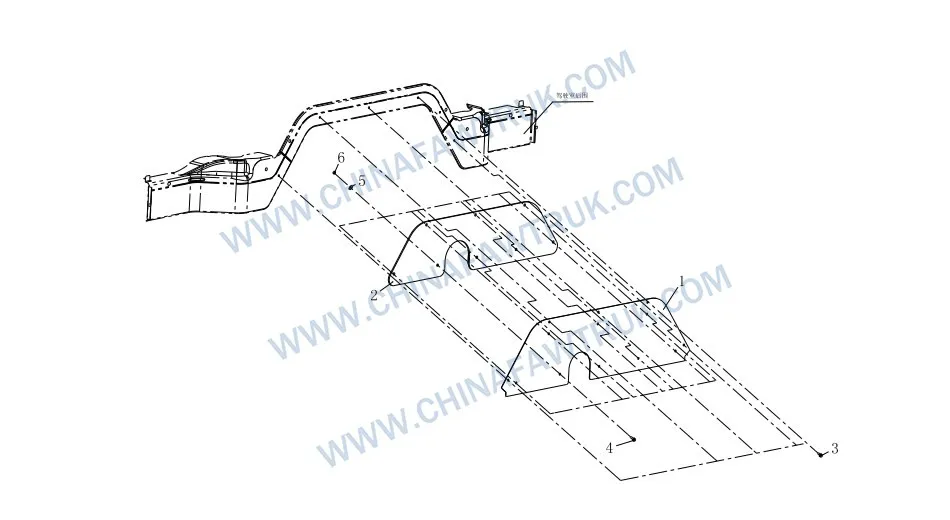

Звукоизоляционная панель задней части двигателя: Развертывание 28 Стратегические компоненты для акустической изоляции

The Звукоизоляционная панель задней части двигателя Логическая сборка представляет собой сложную систему шумоподавления, разработанную специально для Самосвал FAW CA3250P66K24L1TE5Z. Работа в суровых акустических условиях тяжелых горнодобывающих предприятий, этот узел служит основным барьером между дизельным двигателем высокого давления и конструкцией шасси автомобиля.. Эффективно поглощая механический шум и отклоняя тепловую энергию., а Звукоизоляционная панель задней части двигателя повышает комфорт оператора и снижает шумовое загрязнение окружающей среды, обеспечение того, чтобы Звукоизоляционная панель задней части двигателя остается важнейшим фактором соответствия современным операциям флота в Российской Арктике.

Звукоизоляционная панель задней части двигателя

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 |

5103511-55р |

Крепежная пластина задней шумоизоляционной панели двигателя |

1 |

| 2 |

5103513-55р |

Звукоизоляционная панель задней части двигателя |

1 |

| 3 |

CQ1460616 |

Комбинированный болт |

5 |

| 4 |

CQ1460620 |

Комбинированный болт |

7 |

| 5 |

Q40206 |

Большая шайба |

7 |

| 6 |

CQ34006 |

Шестигранный орех |

7 |

Акустическое демпфирование и материаловедение

Основным функциональным элементом этого узла является Звукоизоляционная панель задней части двигателя (Часть №. 5103513-55р). Этот компонент не представляет собой простой лист пластика.; это многослойный акустический барьер, разработанный специально для частотного диапазона дизельного двигателя большой мощности.. Состав материала, обозначается “55р” суффикс, указывает на специализированную резино-полимерную смесь, сохраняющую свою плотность и демпфирующие характеристики даже при минусовых температурах русской зимы.. Стандартные изоляционные материалы часто становятся хрупкими и теряют свои акустические свойства при замерзании., но Звукоизоляционная панель задней части двигателя остается гибким, эффективно поглощает структурные вибрации.

Дизайн Звукоизоляционная панель задней части двигателя имеет текстурированную поверхность, которая рассеивает звуковые волны, предотвращая их отражение от панели и усиление шума двигателя.. Эта технология имеет решающее значение для снижения общего уровня шума самосвала., что является ключевым требованием для работы вблизи жилых районов или чувствительных экологических зон.. Улавливая воздушный шум внутри своей клеточной структуры, а Звукоизоляционная панель задней части двигателя значительно снижает уровень децибел, доходящий до салона. Это сокращение, предусмотренное Звукоизоляционная панель задней части двигателя напрямую способствует снижению утомляемости водителя во время длительных смен.

Более того, а Звукоизоляционная панель задней части двигателя действует как тепловой экран. Расположен в непосредственной близости к задней части блока двигателя., он подвергается значительному лучистому теплу. Материал 55R разработан таким образом, чтобы противостоять термическому разложению., предотвращение деформации или плавления. Одновременно, а Звукоизоляционная панель задней части двигателя защищает компоненты шасси позади него от интенсивного нагрева двигателя, обеспечение того, чтобы гидравлические линии и жгуты проводов, расположенные поблизости, не подвергались опасным скачкам температуры., сохранение долговечности вспомогательных систем автомобиля за счет прочной конструкции Звукоизоляционная панель задней части двигателя.

Структурная поддержка: Крепежная пластина

Мягкий акустический материал изоляционной панели требует жесткого каркаса для сохранения формы и положения внутри помещения. Звукоизоляционная панель задней части двигателя сборка. Это функция Крепежная пластина задней шумоизоляционной панели двигателя (Часть №. 5103511-55р). Этот металлический компонент действует как структурная основа сборки., обеспечение ряда жестких точек крепления для гибкого изоляционного материала. Без Крепежная пластина задней шумоизоляционной панели двигателя, изоляционная панель прогнется под собственным весом или деформируется под действием аэродинамического сопротивления и вибрации двигателя., оказание Звукоизоляционная панель задней части двигателя неэффективный.

Интерфейс между Звукоизоляционная панель задней части двигателя и Крепежная пластина задней шумоизоляционной панели двигателя имеет решающее значение. На пластине проштампованы ребра жесткости для предотвращения резонанса.. Если бы фиксирующая пластина вибрировала с той же частотой, что и двигатель, оно само станет источником шума. Инженеры FAW оптимизировали массу и жесткость автомобиля. Крепежная пластина задней шумоизоляционной панели двигателя чтобы гарантировать, что он остается инертным, действует исключительно как опорная структура. The “55р” Спецификация на пластине, вероятно, относится к соответствующему антикоррозийному покрытию, которое защищает металл от агрессивной соленой среды., обеспечение Звукоизоляционная панель задней части двигателя противостоит ржавчине.

Правильное выравнивание Крепежная пластина задней шумоизоляционной панели двигателя необходим для эффективной герметизации моторного отсека. Зазоры между панелью и блоком двигателя обеспечивают выход шума и попадание грязи.. Фиксирующая пластина гарантирует, что Звукоизоляционная панель задней части двигателя прочно удерживается на уплотнительных поверхностях, создание сплошного акустического барьера. Эта структурная целостность жизненно важна для поддержания “тихая зона” вокруг шасси, демонстрируя важность этого металлического компонента в общем Звукоизоляционная панель задней части двигателя сборка.

Крепление логики: Комбинированные болты

Для фиксации сборки требуется надежная стратегия крепления., используя два варианта Комбинированный болт: Часть №. CQ1460616 (Кол-во 5) и номер детали. CQ1460620 (Кол-во 7). Термин “Комбинированный болт” имеет большое значение в контексте Звукоизоляционная панель задней части двигателя. Это указывает на то, что эти крепежные детали поставляются с предварительно собранными невыпадающими шайбами — обычно это плоская шайба и разрезная стопорная шайба.. Такая интеграция гарантирует, что критический механизм блокировки никогда не будет упущен во время сборки., что имеет решающее значение для предотвращения Звукоизоляционная панель задней части двигателя от вибрации.

Разница в длине между двумя Комбинированный болт варианты (16мм против. 20мм) учитывает различную толщину монтажного комплекта в разных точках шасси. Использование более короткого болта в глубоком отверстии приведет к недостаточному зацеплению резьбы., в то время как использование более длинного болта в неглубоком отверстии может привести к провалу. Конкретный выбор этих Комбинированный болт единиц гарантирует, что Крепежная пластина задней шумоизоляционной панели двигателя зажат с правильным усилием во всех двенадцати точках крепления, равномерно распределяя нагрузку по Звукоизоляционная панель задней части двигателя структура.

Обработка поверхности изделия Комбинированный болт также является ключевым фактором долговечности Звукоизоляционная панель задней части двигателя. Расположен в задней части двигателя, эти крепления подвергаются воздействию дорожных брызг, нагревать, и коррозийные противогололедные соли. Высококачественные антикоррозийные покрытия, например, цинковые хлопья, необходимы для предотвращения заедания болтов в гайках. Заклинившие болты превращают простую замену панели в трудоемкий ремонт, включающий сверление и нарезание резьбы.. Использование этих специализированных болтов гарантирует, что Звукоизоляционная панель задней части двигателя сохраняет работоспособность на протяжении всего срока службы грузовика.

Распределение нагрузки: Шайбы и гайки

Для защиты мягкого материала Звукоизоляционная панель задней части двигателя от повреждений при установке, сборка использует Большая шайба (Часть №. Q40206). Семь из этих блоков стратегически расположены в точках крепления, где в противном случае головка болта прижималась бы непосредственно к изоляционному материалу. Звукоизоляционная панель задней части двигателя. The Большая шайба увеличивает площадь поверхности, к которой прикладывается сила зажима, предотвращение раздавливания болтом акустического полимера или полного его прорыва. Это необходимо для сохранения структурной целостности здания. Звукоизоляционная панель задней части двигателя.

Для крепления болтов предусмотрены семь единиц Шестигранный орех (Часть №. CQ34006). Эти гайки работают в тандеме с Комбинированный болт создать безопасный, виброустойчивое соединение для Звукоизоляционная панель задней части двигателя. Во многих местах шасси, резьбовые отверстия отсутствуют, что требует использования конфигурации со сквозными болтами и гайками.. The Шестигранный орех обеспечивает надежную точку крепления, позволяя Крепежная пластина задней шумоизоляционной панели двигателя плотно прилегать к направляющим шасси, обеспечение Звукоизоляционная панель задней части двигателя не смещается во время работы.

Взаимодействие между Большая шайба, а Комбинированный болт, и Шестигранный орех создает систему крепления, которая компенсирует тепловое расширение внутри Звукоизоляционная панель задней части двигателя система. По мере нагрева двигателя пластиковая панель расширяется., большая площадь поверхности шайбы допускает небольшое движение, не вызывая трещин под напряжением. Такая гибкость является отличительной чертой Звукоизоляционная панель задней части двигателя дизайн, обеспечение того, чтобы сборка могла без сбоев выдерживать экстремальные температурные циклы российского климата., тем самым сохраняя эффективность Звукоизоляционная панель задней части двигателя.

Заключение: Тихий страж

The Звукоизоляционная панель задней части двигателя является важнейшим компонентом для эксплуатационной доработки самосвала FAW CA3250.. За счет интеграции акустических демпфирующих свойств Звукоизоляционная панель задней части двигателя с жесткостью конструкции Крепежная пластина задней шумоизоляционной панели двигателя, FAW предлагает решение, которое эффективно снижает шум и нагрев.. Надежная система крепления, включая Комбинированный болт, Большая шайба, и Шестигранный орех, гарантирует, что защита, обеспечиваемая Звукоизоляционная панель задней части двигателя остается на месте, несмотря на жестокую вибрацию горнодобывающих работ.

Для ремонтных бригад, обеспечение целостности Звукоизоляционная панель задней части двигателя жизненно важно. Панель отсутствует или незакреплена Комбинированный болт может привести к повышенному шуму в салоне и потенциальному тепловому повреждению компонентов шасси.. Используя оригинальные детали и придерживаясь правильной логики сборки., операторы могут гарантировать, что их автопарк продолжает работать тихо и эффективно. The Звукоизоляционная панель задней части двигателя является свидетельством детального проектирования, необходимого для удовлетворения высоких стандартов современной логистики тяжелых грузов на Севере России..

Упаковка и логистика

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..