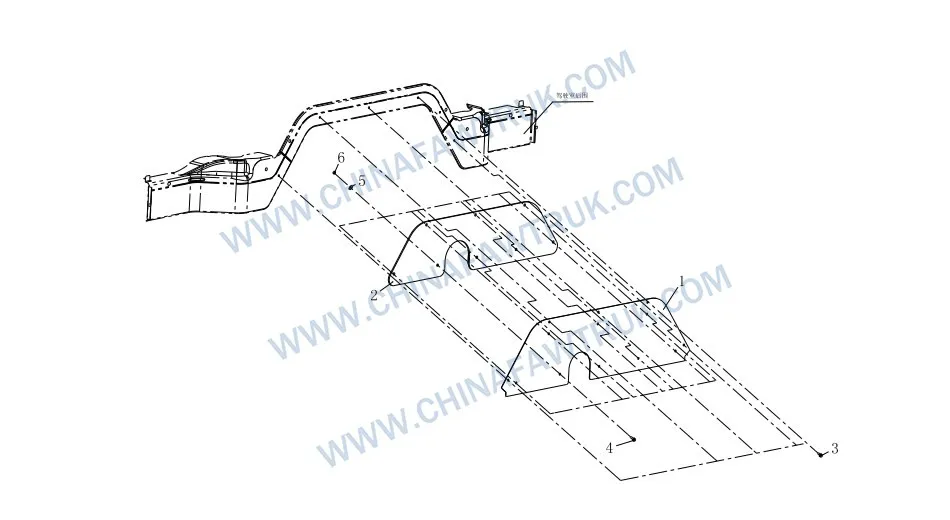

Panel de aislamiento acústico del motor trasero: Implementando 28 Componentes Estratégicos para el Aislamiento Acústico

El Panel de aislamiento acústico del motor trasero El conjunto lógico es un sofisticado sistema de supresión de ruido diseñado específicamente para Camión volquete FAW CA3250P66K24L1TE5Z. Operando en el duro ambiente acústico de la minería pesada, Este conjunto sirve como barrera principal entre el motor diésel de alto decibelio y la estructura del chasis del vehículo.. Absorbiendo eficazmente el ruido mecánico y desviando la energía térmica., el Panel de aislamiento acústico del motor trasero mejora la comodidad del operador y reduce la contaminación acústica ambiental, asegurando que el Panel de aislamiento acústico del motor trasero sigue siendo un factor de cumplimiento crítico para las operaciones de flotas modernas en el Ártico ruso.

Panel de aislamiento acústico del motor trasero

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 |

5103511-55R |

Placa de fijación del panel de aislamiento acústico trasero del motor |

1 |

| 2 |

5103513-55R |

Panel de aislamiento acústico trasero del motor |

1 |

| 3 |

CQ1460616 |

Perno combinado |

5 |

| 4 |

CQ1460620 |

Perno combinado |

7 |

| 5 |

Q40206 |

Lavadora grande |

7 |

| 6 |

CQ34006 |

Tuerca hexagonal |

7 |

Amortiguación acústica y ciencia de los materiales.

El principal elemento funcional de este conjunto es el Panel de aislamiento acústico trasero del motor (Número de pieza. 5103513-55R). Este componente no es una simple lámina de plástico.; Es una barrera acústica de múltiples capas diseñada específicamente para el rango de frecuencia de un motor diésel de servicio pesado.. La composición material, denotado por el “55R” sufijo, indica una mezcla especializada de caucho y polímero que mantiene su densidad y características de amortiguación incluso en las temperaturas bajo cero del invierno ruso.. Los materiales aislantes estándar a menudo se vuelven quebradizos y pierden sus propiedades acústicas cuando se congelan., pero el Panel de aislamiento acústico del motor trasero permanece flexible, Absorber eficazmente las vibraciones estructurales..

El diseño de la Panel de aislamiento acústico trasero del motor Incorpora una superficie texturizada que rompe las ondas sonoras., evitando que se reflejen en el panel y amplifiquen el ruido del motor. Esta tecnología es crucial para reducir el ruido general del camión volquete., que es un requisito clave para operar cerca de áreas residenciales o zonas ambientales sensibles. Atrapando el ruido aéreo dentro de su estructura celular., el Panel de aislamiento acústico del motor trasero Reduce significativamente los niveles de decibelios que llegan a la cabina.. Esta reducción proporcionada por el Panel de aislamiento acústico del motor trasero Contribuye directamente a reducir la fatiga del conductor durante turnos largos..

Además, el Panel de aislamiento acústico del motor trasero actúa como un escudo térmico. Ubicado muy cerca de la parte trasera del bloque del motor., está expuesto a un calor radiante significativo. El material 55R está diseñado para resistir la degradación térmica., evitando que se deforme o se derrita. Simultáneamente, el Panel de aislamiento acústico del motor trasero Protege los componentes del chasis detrás de él del intenso calor del motor., Asegurarse de que las líneas hidráulicas y los mazos de cables ubicados en las proximidades no estén sujetos a picos de temperatura peligrosos., Preservar la longevidad de los sistemas auxiliares del vehículo a través del diseño robusto del Panel de aislamiento acústico del motor trasero.

Soporte estructural: La placa de fijación

El material acústico blando del panel aislante requiere un esqueleto rígido para mantener su forma y posición dentro del Panel de aislamiento acústico del motor trasero asamblea. Esta es la función del Placa de fijación del panel de aislamiento acústico trasero del motor (Número de pieza. 5103511-55R). Este componente metálico actúa como columna vertebral estructural del conjunto., Proporcionar una serie de puntos de montaje rígidos para el material aislante flexible.. sin el Placa de fijación del panel de aislamiento acústico trasero del motor, el panel aislante se hundiría por su propio peso o se deformaría bajo la presión de la resistencia aerodinámica y la vibración del motor., renderizando el Panel de aislamiento acústico del motor trasero ineficaz.

La interfaz entre el Panel de aislamiento acústico trasero del motor y el Placa de fijación del panel de aislamiento acústico trasero del motor es critico. La placa está estampada con nervaduras de refuerzo para evitar la resonancia.. Si la placa de fijación vibrara a la misma frecuencia que el motor, Se convertiría en una fuente de ruido.. Los ingenieros de FAW han ajustado la masa y la rigidez del Placa de fijación del panel de aislamiento acústico trasero del motor para garantizar que permanezca inerte, actuando puramente como una estructura de soporte. El “55R” La especificación en la placa probablemente se refiere a un revestimiento resistente a la corrosión que protege el metal del duro ambiente salino., asegurando el Panel de aislamiento acústico del motor trasero resiste el óxido.

Alineación adecuada del Placa de fijación del panel de aislamiento acústico trasero del motor Es esencial para el sellado eficaz del compartimento del motor.. Los espacios entre el panel y el bloque del motor permiten que el ruido se escape y la suciedad entre. La placa de fijación garantiza que el Panel de aislamiento acústico del motor trasero se mantiene firmemente contra sus superficies de sellado, creando una barrera acústica continua. Esta integridad estructural es vital para mantener la “zona tranquila” alrededor del chasis, demostrando la importancia de este componente metálico en el conjunto Panel de aislamiento acústico del motor trasero asamblea.

Lógica de fijación: Pernos combinados

Asegurar el conjunto requiere una estrategia de sujeción sólida, utilizando dos variantes del Perno combinado: Número de pieza. CQ1460616 (Cantidad 5) y número de pieza. CQ1460620 (Cantidad 7). El término “Perno combinado” es significativo en el contexto de la Panel de aislamiento acústico del motor trasero. It indicates that these fasteners come with pre-assembled captive washers—typically a flat washer and a split lock washer. This integration ensures that the critical locking mechanism is never omitted during assembly, which is vital for preventing the Panel de aislamiento acústico del motor trasero de vibrar suelto.

The difference in length between the two Perno combinado variantes (16mm vs. 20milímetros) caters to the varying thickness of the mounting stack-up at different points on the chassis. Using the shorter bolt in a deep hole would result in insufficient thread engagement, while using the longer bolt in a shallow hole could lead to bottoming out. The specific selection of these Perno combinado units ensures that the Placa de fijación del panel de aislamiento acústico trasero del motor is clamped with the correct force across all twelve mounting points, distributing the load evenly across the Panel de aislamiento acústico del motor trasero estructura.

El tratamiento superficial del Perno combinado is also a key durability factor for the Panel de aislamiento acústico del motor trasero. Ubicado en la parte trasera del motor., Estos sujetadores están expuestos a las salpicaduras de la carretera., calor, y sales de deshielo corrosivas. Recubrimientos anticorrosión de alta calidad., como escamas de zinc, son esenciales para evitar que los pernos se atasquen en las tuercas. Los pernos atascados convierten un simple reemplazo de panel en una reparación que requiere mucho tiempo y requiere taladrar y roscar.. El uso de estos pernos especializados garantiza que el Panel de aislamiento acústico del motor trasero permanece útil durante toda la vida útil del camión.

Distribución de carga: Arandelas y Tuercas

Para proteger el material blando del Panel de aislamiento acústico trasero del motor por daños durante la instalación, el conjunto utiliza el Lavadora grande (Número de pieza. Q40206). Siete de estas unidades están ubicadas estratégicamente en puntos de montaje donde, de otro modo, la cabeza del perno se apoyaría directamente sobre el material aislante del Panel de aislamiento acústico del motor trasero. El Lavadora grande aumenta la superficie sobre la que se aplica la fuerza de sujeción, evitando que el perno aplaste el polímero acústico o lo atraviese por completo. Esto es esencial para mantener la integridad estructural del Panel de aislamiento acústico del motor trasero.

Para asegurar los pernos hay siete unidades del Tuerca hexagonal (Número de pieza. CQ34006). Estas tuercas funcionan en conjunto con el Perno combinado para crear un seguro, conexión resistente a vibraciones para Panel de aislamiento acústico del motor trasero. En muchos lugares del chasis., los agujeros roscados no están disponibles, lo que requiere el uso de una configuración de perno pasante y tuerca. El Tuerca hexagonal proporciona un punto de anclaje confiable, permitiendo el Placa de fijación del panel de aislamiento acústico trasero del motor para ser intercalado firmemente contra los rieles del chasis, asegurando el Panel de aislamiento acústico del motor trasero no cambia durante la operación.

La interacción entre el Lavadora grande, el Perno combinado, y el Tuerca hexagonal crea un sistema de sujeción que se adapta a la expansión térmica dentro del Panel de aislamiento acústico del motor trasero sistema. A medida que el motor se calienta y el panel de plástico se expande, La gran superficie de la lavadora permite un ligero movimiento sin provocar grietas por tensión.. Esta flexibilidad es un sello distintivo de la Panel de aislamiento acústico del motor trasero diseño, garantizar que el conjunto pueda soportar los ciclos de temperatura extrema del clima ruso sin fallar, manteniendo así la eficacia de la Panel de aislamiento acústico del motor trasero.

Conclusión: Un guardián silencioso

El Panel de aislamiento acústico del motor trasero es un componente crítico para el refinamiento operativo del camión volquete FAW CA3250. Al integrar las propiedades de amortiguación acústica del Panel de aislamiento acústico trasero del motor con la rigidez estructural del Placa de fijación del panel de aislamiento acústico trasero del motor, FAW ofrece una solución que mitiga eficazmente el ruido y el calor. El robusto sistema de fijación, que comprende el Perno combinado, Lavadora grande, y Tuerca hexagonal, garantiza que la protección ofrecida por el Panel de aislamiento acústico del motor trasero permanece en su lugar a pesar de la brutal vibración de las operaciones mineras.

Para equipos de mantenimiento, asegurando la integridad de la Panel de aislamiento acústico del motor trasero es vital. Un panel faltante o suelto Perno combinado puede provocar un aumento del ruido en la cabina y posibles daños por calor en los componentes del chasis. Utilizando piezas originales y respetando la lógica de montaje correcta, Los operadores pueden garantizar que su flota continúe operando de manera silenciosa y eficiente.. El Panel de aislamiento acústico del motor trasero Es un testimonio de la ingeniería detallada necesaria para cumplir con los altos estándares de la logística moderna de carga pesada en el norte de Rusia..

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.