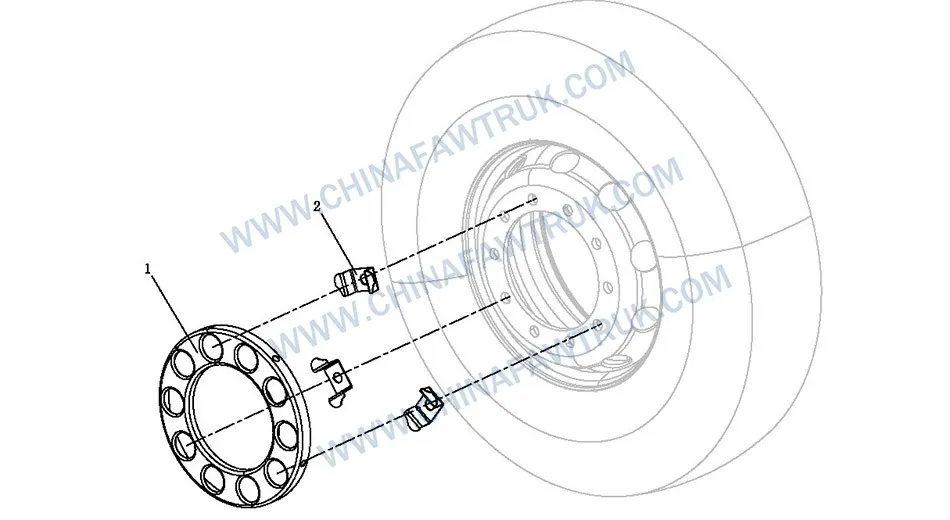

Ensemble d'enjoliveur de roue russe FAW: Ingénierie 3 Composants essentiels pour l’intégrité du pôle arctique

L'ensemble d'enjoliveur russe FAW est un élément protecteur et fonctionnel essentiel du camion-benne robuste CA3250P66K24L1TE5Z.. Bien qu'apparemment mineur, l'objectif principal de l'ensemble d'enjoliveur de roue russe FAW est de protéger l'extrémité de l'essieu, écrous de roue, et les composants critiques du moyeu provenant de la boue routière corrosive, boue, et la glace répandue dans le secteur minier sibérien. Conçu avec le “55R.” spécification à froid, cet assemblage utilise des matériaux spécialisés pour résister à la rupture fragile et maintenir l'intégrité structurelle à des températures extrêmement basses. La longévité de l'ensemble du système de moyeu de roue repose en grande partie sur la barrière de protection fournie par l'ensemble d'enjoliveur de roue russe FAW..

Ensemble d'enjoliveur de roue russe FAW

Couvrir la science des matériaux et la résistance thermique

Le principal composant visuel, l'enjoliveur (Partie no. 3102011-55R.), est le bouclier extérieur immédiat. La sélection du matériau pour l’assemblage d’enjoliveurs russes FAW est cruciale, dicté par la nécessité de résister aux chocs à des températures inférieures à -40°C. Les polymères standards deviennent fragiles et se brisent à froid, risquer d'exposer les composants du moyeu de roue. Le “55R.” Le code sur l'enjoliveur signifie un polymère ou un matériau composite avec une faible température de transition vitreuse, garantir que l'ensemble d'enjoliveur russe FAW conserve son élasticité et sa résistance aux chocs dans la plage thermique extrême de l'environnement russe.

Cette conception spécifique de l'enjoliveur minimise l'accumulation de glace interne. La géométrie de l'enjoliveur de roue russe FAW est optimisée pour empêcher la neige et la glace de s'accumuler dans l'évidement autour des écrous de roue., ce qui pourrait autrement perturber l’équilibre dynamique de la roue. Il est essentiel de maintenir une surface intérieure propre sur l'ensemble d'enjoliveur de roue russe FAW pour réduire les vibrations et empêcher la corrosion de se propager vers la face du joint d'essieu., améliorant ainsi la durabilité globale des composants du moyeu. L'intégrité de l'enjoliveur influence directement la durée de vie des goujons et écrous de roue..

La fonction secondaire de l'ensemble d'enjoliveur russe FAW est l'atténuation de la corrosion.. En créant une barrière physique, l'enjoliveur de roue empêche les gravillons abrasifs et les solutions de sel corrosives d'atteindre les écrous de roue chromés ou zingués. C'est vital pour la sécurité, car une exposition constante entraîne une adhérence de la rouille, rendant le retrait des roues difficile et risquant d'endommager les fixations. La longévité de l'enjoliveur russe FAW protège le matériel de montage de la roue., garantir que les roues peuvent être entretenues rapidement et en toute sécurité, même après des années d'utilisation dans des environnements difficiles.

En outre, la présence de l'enjoliveur améliore l'attrait esthétique du camion, fournir un nettoyage, finition professionnelle, même si la fonction principale de l'enjoliveur russe FAW est la protection. Le composant est conçu pour être amovible, permettant un accès facile aux écrous de roue et au moyeu de roue pour les contrôles d'entretien de routine et la lubrification sans effort excessif. L'ensemble de l'enjoliveur global (Partie no. 3102010-55R.) est rigoureusement testé pour la résistance aux UV, malgré le froid, et résistance aux produits de nettoyage chimiques.

Support structurel et résistance aux vibrations

La rigidité de l'ensemble d'enjoliveur russe FAW est assurée par trois supports individuels – Enjoliveur (Partie no. 3102012-55R.) composants. Ces supports forment un système de montage triangulaire, la configuration géométrique la plus stable et la plus facile à aligner. Les supports font office de lien rigide entre les goujons de roue rotatifs (ou bride de moyeu) et l'enjoliveur léger (Partie no. 3102011-55R.). Leur rôle structurel principal est d'absorber les vibrations de rotation et les forces de déplacement latéral de la roue., en maintenant fermement l'enjoliveur de roue en place. La stabilité assurée par les trois supports – Les composants de l'enjoliveur de roue empêchent l'enjoliveur principal de se détacher à vitesse d'autoroute., ce qui pourrait constituer un danger routier dangereux pour les autres véhicules.

Le support – Les composants de l'enjoliveur sont généralement fabriqués à partir d'acier embouti ou moulé robuste., mettant en vedette un “55R.” revêtement anticorrosion et tolérances dimensionnelles spécifiques. L'alignement de ces trois supports doit être parfait; un mauvais alignement entraîne un positionnement inégal de l'enjoliveur de roue, entraînant une traînée aérodynamique et des vibrations excessives, ce qui peut fatiguer le métal du support. La durabilité de l'ensemble d'enjoliveur russe FAW dépend directement de l'intégrité de ces trois supports.. La longévité de l'ensemble d'enjoliveurs russes FAW témoigne de cette logique d'ingénierie..

Le mécanisme de montage du support – L'enjoliveur de roue est conçu pour la sécurité et la facilité d'entretien. La connexion aux goujons de roue implique souvent une configuration unique de bride et de boulon qui minimise le risque de desserrage dû à la rotation de la roue.. L'ensemble d'enjoliveur de roue russe FAW garantit que les supports restent serrés contre la surface de la roue., éviter les cliquetis courants dans les véhicules lourds dotés de composants esthétiques mal conçus. La sécurité apportée par les trois Bracket – Les supports d’enjoliveur de roue sont essentiels.

En outre, le support – Les composants de l'enjoliveur servent à protéger l'enjoliveur lui-même des contraintes de flexion excessives.. L'enjoliveur (Partie no. 3102011-55R.) est conçu principalement pour l’esthétique et la résistance aux chocs légers. Les trois points de montage robustes fournis par le support – L'enjoliveur de roue répartit les forces externes, empêchant l'enjoliveur de se fissurer lorsqu'il est touché par de la boue ou des débris gelés, assurer la fonction de protection continue de l'ensemble de l'ensemble d'enjoliveur russe FAW. L'ensemble d'enjoliveur complet (Partie no. 3102010-55R.) Doit être utilisé pour garantir le montage.

Protocoles d'inspection et longévité des composants

L'inspection de routine de l'ensemble d'enjoliveur de roue russe FAW est essentielle pour maintenir la santé des extrémités de roue.. Les principaux points d'intérêt sont les trois supports – Enjoliveur (Partie no. 3102012-55R.) composants. Les mécaniciens devraient vérifier les fissures de contrainte, flexion, ou une corrosion excessive, car tout dommage compromet la capacité du support à maintenir l'enjoliveur de roue (Partie no. 3102011-55R.). Un enjoliveur desserré présente un risque pour la sécurité, car il pourrait se détacher à grande vitesse.

La prévention de la corrosion est vitale pour les composants métalliques de l'ensemble d'enjoliveur de roue russe FAW. Le support – Les composants de l'enjoliveur doivent conserver leur revêtement anticorrosion. Si de la rouille se développe, il peut saisir les supports sur les goujons du moyeu, rendant le retrait pour l'entretien des pneus difficile et risquant d'endommager les filetages du moyeu. Nettoyage régulier de l'ensemble de l'enjoliveur russe FAW avec de l'eau et du savon doux. (pour éliminer les résidus de sel) est une pratique recommandée.

Lors du remplacement de composants, l'ensemble de l'enjoliveur complet (Partie no. 3102010-55R.) ou ses sous-composants doivent provenir du “55R.” spécification. Utilisation de pièces génériques dans l'ensemble d'enjoliveur russe FAW, comme les couvercles en plastique standard, risque une défaillance immédiate dès le premier impact dans des conditions inférieures à zéro. Les pièces d'origine FAW garantissent la résistance aux basses températures et le montage précis requis pour maintenir les normes de protection établies par la conception de l'ensemble d'enjoliveur russe FAW.. La précision dimensionnelle du support – L'enjoliveur de roue est la clé d'un serrage serré., support stable.

La facilité d'entretien de l'extrémité de la roue est améliorée par la facilité de retrait de l'ensemble d'enjoliveur de roue russe FAW.. Cet accès rapide permet aux techniciens d'inspecter la zone du joint du moyeu et d'effectuer des contrôles de couple essentiels sur les écrous de roue et de vérifier l'état du joint d'essieu sans un long processus de démontage., ce qui constitue un facteur d'efficacité clé pour la préparation opérationnelle de la flotte de camions-bennes CA3250P66K24L1TE5Z dans les conditions difficiles du nord de la Russie.. La longévité des roulements de moyeu et des goujons bénéficie directement de la protection continue offerte par l'ensemble d'enjoliveur russe FAW..

Répartition des composants: Ensemble de couvercle de roue

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| – | 3102010-55R. | Ensemble de couvercle de roue | 1 |

| 1 | 3102011-55R. | Enjoliveur | 1 |

| 2 | 3102012-55R. | Support – Enjoliveur | 3 |

Conclusion: Protection et efficacité

L'ensemble d'enjoliveurs de roue russe FAW fait partie intégrante du maintien de l'efficacité et de la sécurité des extrémités de roue.. En protégeant les fixations et les composants de moyeu critiques de l'environnement routier corrosif, l'enjoliveur (Partie no. 3102011-55R.) et ses trois supports – Les supports d'enjoliveur garantissent une fiabilité à long terme. Le “55R.” la spécification garantit la survie du composant dans des conditions arctiques, une nécessité pour le calendrier opérationnel exigeant du camion-benne.

Pour les exploitants de flotte, l'entretien du support – Enjoliveur (Partie no. 3102012-55R.) est essentiel pour éviter les vibrations et la perte du couvercle. L'utilisation de pièces d'origine FAW pour l'ensemble d'enjoliveur russe FAW garantit que les propriétés par temps froid et l'intégrité structurelle de l'ensemble du système d'extrémité de roue sont préservées., maximiser la disponibilité et la fiabilité dans l’environnement sibérien.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.