FAW Russian Wheel Cover Assembly: Engineering 3 Core Components for Arctic Hub Integrity

The FAW Russian Wheel Cover Assembly is a vital protective and functional element of the CA3250P66K24L1TE5Z heavy-duty dump truck. Though seemingly minor, the primary purpose of the FAW Russian Wheel Cover Assembly is to shield the axle end, wheel nuts, and critical hub components from the corrosive road slurry, mud, and ice prevalent in the Siberian mining sector. Engineered with the “55R” cold-specification, this assembly utilizes specialized materials to resist brittle fracture and maintain structural integrity across extreme low temperatures. The longevity of the entire wheel hub system relies heavily on the protective barrier provided by the FAW Russian Wheel Cover Assembly.

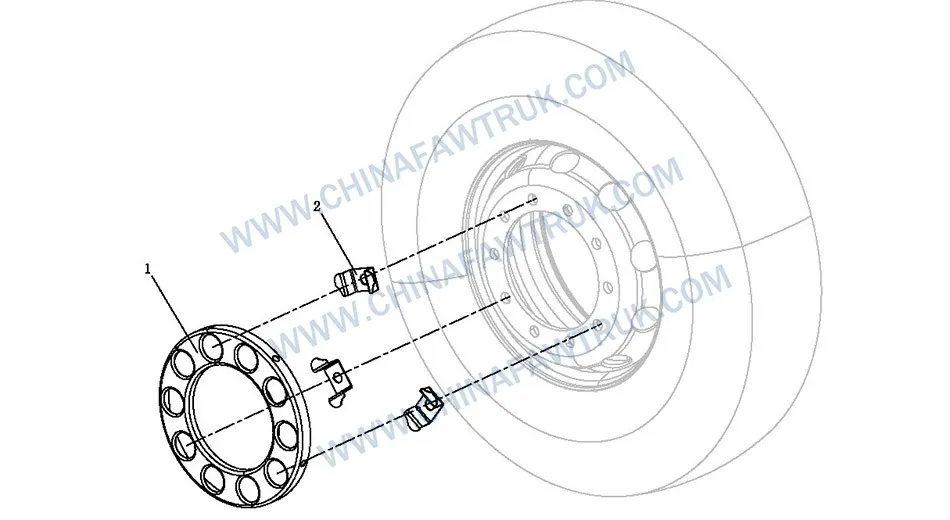

FAW Russian Wheel Cover Assembly

Cover Material Science and Thermal Resistance

The main visual component, the Wheel Cover (Part No. 3102011-55R), is the immediate external shield. The selection of material for the FAW Russian Wheel Cover Assembly is crucial, dictated by the need to resist impact at temperatures below -40°C. Standard polymers become fragile and shatter when cold, risking the exposure of the wheel hub components. The “55R” code on the Wheel Cover signifies a polymer or composite material with a low glass transition temperature, ensuring the FAW Russian Wheel Cover Assembly maintains its elasticity and impact resistance across the extreme thermal range of the Russian environment.

This specific Wheel Cover design minimizes internal ice accumulation. The geometry of the FAW Russian Wheel Cover Assembly is optimized to prevent snow and ice from packing into the recess around the lug nuts, which could otherwise throw the wheel’s dynamic balance off. Maintaining a clean inner surface on the FAW Russian Wheel Cover Assembly is critical for reducing vibration and preventing corrosion creep toward the axle seal face, thus enhancing the overall durability of the hub components. The integrity of the Wheel Cover directly influences the lifespan of the wheel studs and nuts.

The secondary function of the FAW Russian Wheel Cover Assembly is corrosion mitigation. By creating a physical barrier, the Wheel Cover prevents abrasive road grit and corrosive salt solutions from reaching the chrome or zinc-plated lug nuts. This is vital for safety, as constant exposure leads to rust seizure, making wheel removal difficult and risking damage to the fasteners. The longevity of the FAW Russian Wheel Cover Assembly protects the wheel mounting hardware, ensuring that the wheels can be serviced quickly and safely, even after years of use in harsh environments.

Furthermore, the presence of the Wheel Cover enhances the aesthetic appeal of the truck, providing a clean, professional finish, even if the primary function of the FAW Russian Wheel Cover Assembly is protection. The component is designed to be removable, allowing easy access to the lug nuts and the wheel hub for routine maintenance checks and lubrication without excessive effort. The overall Wheel Cover Assembly (Part No. 3102010-55R) is rigorously tested for UV resistance, despite the cold environment, and resistance to chemical cleaning agents.

Structural Support and Vibration Resistance

The rigidity of the FAW Russian Wheel Cover Assembly is provided by three individual Bracket – Wheel Cover (Part No. 3102012-55R) components. These brackets form a triangular mounting system, the most stable and easily aligned geometric configuration. The brackets act as the rigid link between the rotating wheel studs (or hub flange) and the lightweight Wheel Cover (Part No. 3102011-55R). Their primary structural role is to absorb the rotational vibration and lateral displacement forces of the wheel, holding the Wheel Cover firmly in place. The stability provided by the three Bracket – Wheel Cover components is what keeps the main Wheel Cover from detaching at highway speeds, which could be a dangerous road hazard for other vehicles.

The Bracket – Wheel Cover components are typically manufactured from robust stamped or cast steel, featuring a “55R” anti-corrosion coating and specific dimensional tolerances. The alignment of these three brackets must be perfect; misalignment causes the Wheel Cover to sit unevenly, resulting in aerodynamic drag and excessive vibration, which can fatigue the bracket metal. The durability of the FAW Russian Wheel Cover Assembly is directly dependent on the integrity of these three supporting brackets. The longevity of the FAW Russian Wheel Cover Assembly is a testament to this engineering logic.

The mounting mechanism of the Bracket – Wheel Cover is engineered for both security and serviceability. The connection to the wheel studs often involves a unique flange and bolt configuration that minimizes the risk of loosening due to the wheel’s rotation. The FAW Russian Wheel Cover Assembly ensures that the brackets remain tight against the wheel surface, preventing the rattling that is common in heavy vehicles with poorly designed cosmetic components. The security provided by the three Bracket – Wheel Cover supports is vital.

Furthermore, the Bracket – Wheel Cover components serve to protect the Wheel Cover itself from excessive bending stresses. The Wheel Cover (Part No. 3102011-55R) is designed primarily for aesthetics and light impact resistance. The three robust mounting points provided by the Bracket – Wheel Cover assembly distribute external forces, preventing the Wheel Cover from cracking when impacted by frozen mud or debris, ensuring the continuous protective function of the entire FAW Russian Wheel Cover Assembly. The full Wheel Cover Assembly (Part No. 3102010-55R) should be used to guarantee fitment.

Inspection Protocols and Component Longevity

Routine inspection of the FAW Russian Wheel Cover Assembly is essential for maintaining wheel end health. The primary points of focus are the three Bracket – Wheel Cover (Part No. 3102012-55R) components. Mechanics should check for stress cracks, bending, or excessive corrosion, as any damage here compromises the bracket’s ability to hold the Wheel Cover (Part No. 3102011-55R). A loose Wheel Cover Assembly poses a safety risk, as it could detach at speed.

Corrosion prevention is vital for the metallic components of the FAW Russian Wheel Cover Assembly. The Bracket – Wheel Cover components must maintain their anti-corrosion coating. If rust develops, it can seize the brackets onto the hub studs, making removal for tire servicing difficult and risking damage to the hub threads. Regular cleaning of the entire FAW Russian Wheel Cover Assembly with mild soap and water (to remove salt residue) is a recommended practice.

When replacing components, the entire Wheel Cover Assembly (Part No. 3102010-55R) or its sub-components must be sourced with the “55R” specification. Using generic parts in the FAW Russian Wheel Cover Assembly, such as standard plastic covers, risks immediate failure upon first impact in sub-zero conditions. Genuine FAW parts guarantee the low-temperature resistance and precise fitment required to maintain the protection standards set by the FAW Russian Wheel Cover Assembly design. The dimensional accuracy of the Bracket – Wheel Cover is key for a tight, stable mount.

The serviceability of the wheel end is enhanced by the ease of removing the FAW Russian Wheel Cover Assembly. This quick access allows technicians to inspect the hub seal area and perform essential torque checks on lug nuts and check axle seal health without a lengthy disassembly process, which is a key efficiency factor for the operational readiness of the CA3250P66K24L1TE5Z dump truck fleet in the challenging conditions of the Russian North. The longevity of the hub bearings and studs is directly benefited by the continuous protection offered by the FAW Russian Wheel Cover Assembly.

Component Breakdown: Wheel Cover Assembly

| No. |

Part Number |

Part Name |

Qty |

| – | 3102010-55R | Wheel Cover Assembly | 1 |

| 1 | 3102011-55R | Wheel Cover | 1 |

| 2 | 3102012-55R | Bracket – Wheel Cover | 3 |

Conclusion: Protection and Efficiency

The FAW Russian Wheel Cover Assembly is an integral component in maintaining the efficiency and safety of the wheel ends. By shielding critical fasteners and hub components from the corrosive road environment, the Wheel Cover (Part No. 3102011-55R) and its three Bracket – Wheel Cover supports ensure long-term reliability. The “55R” specification guarantees the component’s survival in arctic conditions, a necessity for the dump truck’s demanding operational schedule.

For fleet operators, the maintenance of the Bracket – Wheel Cover (Part No. 3102012-55R) is key to preventing vibration and loss of the cover. Utilizing genuine FAW parts for the FAW Russian Wheel Cover Assembly ensures that the cold-weather properties and structural integrity of the entire wheel end system are preserved, maximizing uptime and reliability in the Siberian environment.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.