Cylindre de gamme de vitesses de sous-boîte russe FAW: Commandant 8 Composants stratégiques pour des transitions haut-bas fluides

Le Cylindre de gamme de vitesses de sous-boîte russe FAW L'assemblage logique est le muscle pneumatique derrière la polyvalence de la transmission CA3250P66K24L1TE5Z.. Il est responsable du déplacement physique de la boîte de vitesses auxiliaire entre les gammes haute et basse., doublant efficacement les rapports de démultiplication disponibles. Dans l’environnement glacial russe, où les systèmes pneumatiques sont sujets au givrage et à une réponse lente, cet ensemble garantit que le conducteur peut accéder instantanément au couple nécessaire pour les montées raides ou à la vitesse nécessaire pour les allers-retours sur autoroute.

Ensemble cylindre de gamme de vitesses de sous-boîte russe FAW

Noyau pneumatique: L'ensemble de cylindre

L'actionneur principal de ce système est le Ensemble de cylindre – Sous-boîte (Partie no. 1701640CA9K). Ce composant convertit l'énergie de l'air comprimé en force mécanique linéaire. Au sein du Cylindre de gamme de vitesses de sous-boîte russe FAW architecture, le vérin est une unité à double effet, ce qui signifie qu'il utilise la pression de l'air pour étendre (engager la gamme basse) et la pression de l'air pour se rétracter (engager une gamme haute). Cette conception à déplacement positif est cruciale pour le marché russe. Les vérins à simple effet qui dépendent du rappel par ressort échouent souvent dans l'Arctique parce que la force du ressort ne peut pas vaincre la résistance de l'huile de transmission épaissie et des joints renforcés à -40°C..

Le piston interne du Cylindre de gamme de vitesses de sous-boîte russe FAW utilise des joints toriques ou des joints à lèvres spécialisés à basse température. Ces joints sont formulés à partir d'élastomères avancés qui conservent leur flexibilité par temps extrêmement froid.. Un joint en caoutchouc standard gèlerait fortement, permettant à l'air de contourner le piston. Ce “soufflé” entraîne un changement de vitesse léthargique ou une incapacité à engager complètement la vitesse, menant au redoutable “faux neutre” où la transmission déconnecte le moteur des roues - une situation dangereuse dans une descente glacée.

Le boîtier du cylindre est généralement en aluminium moulé sous pression pour résister à la corrosion due à l'humidité interne.. Les systèmes d’air comprimé des camions accumulent naturellement les condensats d’eau. Si cette eau gèle à l'intérieur du cylindre, il peut verrouiller le piston solidement. Le Cylindre de gamme de vitesses de sous-boîte russe FAW est conçu avec une géométrie interne qui minimise les poches d'eau, permettant de purger le condensat pendant les cycles de fonctionnement. Cette capacité d'auto-nettoyage est une caractéristique de fiabilité essentielle pour les véhicules fonctionnant dans des conditions humides., environnements glacials.

Traduction mécanique: La fourchette de changement de vitesse

La connexion du piston pneumatique au manchon coulissant de l'engrenage est la Fourche de changement de vitesse – Synchroniseur de sous-boîtier (Partie no. 1701632FA0L). Ce composant est la main physique qui déplace les engrenages. Dans le Cylindre de gamme de vitesses de sous-boîte russe FAW système, la fourche doit être incroyablement rigide. Toute déviation ou flexion pendant la course de changement de vitesse entraîne un engagement partiel. Un engagement partiel fait grincer les dents du synchroniseur et éventuellement les dénuder., nécessitant une révision complète de la transmission.

Les bouts de fourche sont équipés de patins d'usure, généralement fabriqué à partir d'acier recouvert de molybdène ou d'un polymère durable. Ces plaquettes roulent dans la rainure du manchon du synchroniseur en rotation.. Dans le Cylindre de gamme de vitesses de sous-boîte russe FAW assemblée, ces points de contact sont soumis à une friction et à une chaleur élevées. Les matériaux sont sélectionnés pour résister à cet environnement sans grippage. La fourche elle-même est fixée à la tige de piston avec un alignement précis. Même un millimètre de désalignement peut provoquer le blocage de la fourche sur le rail de guidage., geler le mécanisme de changement de gamme.

L'interaction entre la fourche et le cylindre est scellée par le Joint – Cylindre de sous-boîte (Partie no. 1701646-A7G). Ce joint remplit une double fonction. Principalement, il ferme la chambre pneumatique, prévenir la perte d'air. Secondairement, il peut servir de cale pour régler la longueur précise de la course du piston. Dans le Cylindre de gamme de vitesses de sous-boîte russe FAW, le maintien de la course correcte est essentiel pour garantir que le synchroniseur est poussé complètement dans le “verrouillage” position mais pas au point qu'il appuie contre la face de l'engrenage, créant de la traînée et de la chaleur.

Logique de sécurité: Boulons filaires et contrôle des vibrations

Le montage de la fourchette de changement de vitesse sur l'arbre est une jonction de sécurité critique. Le Cylindre de gamme de vitesses de sous-boîte russe FAW l'assemblage utilise des Boulon à tête hexagonale avec col de guidage (Partie no. CQ1711250S). Ces boulons comportent un trou percé dans la tête. Cette conception n'est pas destinée à économiser du poids; c'est pour l'application de Ligne de verrouillage en fil d'acier (Partie no. Q50516200).

Dans l'environnement à hautes vibrations à l'intérieur du carter de transmission, Les composés de frein-filet standard peuvent échouer en raison du bain constant d'huile chaude. Le verrouillage mécanique via un fil de sécurité est la référence en matière de fiabilité. Le fil est enfilé à travers les têtes de boulons selon un motif spécifique qui crée une tension dans le sens du serrage.. Si un boulon essaie de se desserrer, le fil le tire plus fort. Cela garantit que la fourchette ne se détache jamais de l'arbre d'actionnement dans le Cylindre de gamme de vitesses de sous-boîte russe FAW système.

Le montage externe du boîtier du cylindre est assuré par Boulon à tête hexagonale (Partie no. CQ1501025S) et Rondelle à ressort (Partie no. Q40310). Ces fixations externes doivent résister aux projections corrosives des sels de déneigement. Le Cylindre de gamme de vitesses de sous-boîte russe FAW les spécifications exigent un placage en zinc-nickel ou similaire de haute qualité sur ces boulons pour éviter le grippage. Un boulon grippé peut transformer un simple remplacement de joint en une tâche cauchemardesque nécessitant de percer et de tarauder le boîtier en aluminium..

Logique de flux: Articulations du coude et distribution d’air

L'acheminement de l'air comprimé vers le cylindre nécessite une interface robuste. Le Assemblage commun du coude (Partie no. 1701670-A7G) est vissé dans les ports du cylindre. Dans les limites étroites du châssis, ces coudes permettent aux conduites d'air en nylon rigide de s'approcher de la transmission au bon angle sans se plier. Les lignes pliées limitent le flux d'air, ralentir la vitesse de changement de vitesse du Cylindre de gamme de vitesses de sous-boîte russe FAW.

Le diamètre interne de ces raccords est calibré pour agir comme un limiteur de contrôle de débit. Si l'air s'engouffre trop vite dans le cylindre, le changement peut être violent, claquant les anneaux de synchronisation ensemble et provoquant une usure. Si trop lent, le changement se bloque. Le Cylindre de gamme de vitesses de sous-boîte russe FAW les raccords modulent le débit d'air pour fournir un, changement de vitesse positif, suffisamment rapide pour la performance mais suffisamment contrôlé pour la longévité.

En outre, les filetages de ces raccords sont généralement recouverts d'un mastic pré-appliqué. Cela évite les fuites d'air qui sont audibles comme un sifflement constant. Dans le Cylindre de gamme de vitesses de sous-boîte russe FAW système, une fuite d'air n'est pas seulement une nuisance; cela fait chuter la pression du système. Si la pression descend en dessous d'un certain seuil (généralement 6 bar), la soupape de protection de plage peut empêcher le changement de vitesse de se produire, laisser le camion coincé en gamme basse sur une autoroute ou en gamme haute dans une fosse.

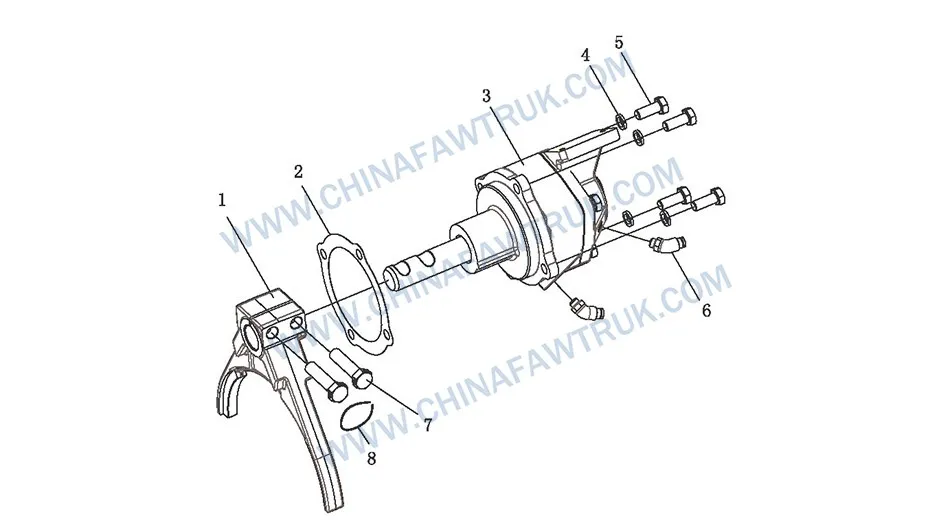

Répartition des composants: 112. Ensemble cylindre de gamme de vitesses de sous-boîte

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | 1701632FA0L | Fourche de changement de vitesse – Synchroniseur de sous-boîtier | 1 |

| 2 | 1701646-A7G | Joint – Cylindre de sous-boîte | 1 |

| 3 | 1701640CA9K | Ensemble de cylindre – Sous-boîte | 1 |

| 4 | Q40310 | Rondelle à ressort | 2 |

| 5 | CQ1501025S | Boulon à tête hexagonale | 2 |

| 6 | 1701670-A7G | Assemblage commun du coude | 2 |

| 7 | CQ1711250S | Boulon à tête hexagonale avec col de guidage | 2 |

| 8 | Q50516200 | Ligne de verrouillage en fil d'acier | 2 |

Conclusion: L'interrupteur pneumatique

Le Cylindre de gamme de vitesses de sous-boîte russe FAW L'ensemble est l'interface de contrôle définitive pour la transmission à partage de gamme. Il allie harmonieusement puissance pneumatique et précision mécanique pour permettre au conducteur de contrôler le couple de sortie du véhicule.. Chaque composant, des joints de piston résistants au froid aux boulons de fourche de changement de vitesse verrouillés par fil, est conçu pour éviter les pannes dans les environnements opérationnels les plus exigeants.

Pour les techniciens de transmission, le message est clair: respecter les détails. Réutiliser un joint écrasé ou ne pas installer le fil de sécurité sur les boulons de fourche compromet l'ensemble de la transmission.. En utilisant le véritable Cylindre de gamme de vitesses de sous-boîte russe FAW pièces détachées et en respectant les procédures d'installation appropriées, les opérateurs veillent à ce que leur flotte reste mobile, productif, et en toute sécurité, quelles que soient les conditions hivernales sibériennes.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.