Cilindro de faixa de engrenagens de sub-caixa russa FAW: Comandando 8 Componentes Estratégicos para Transições Altas-Baixas Perfeitas

O Cilindro de faixa de engrenagens de sub-caixa russa FAW logic assembly is the pneumatic muscle behind the versatility of the CA3250P66K24L1TE5Z transmission. It is responsible for physically shifting the auxiliary gearbox between high and low ranges, effectively doubling the available gear ratios. No ambiente gelado da Rússia, where pneumatic systems are prone to icing and sluggish response, this assembly ensures that the driver can instantly access the torque needed for steep climbs or the speed needed for highway return trips.

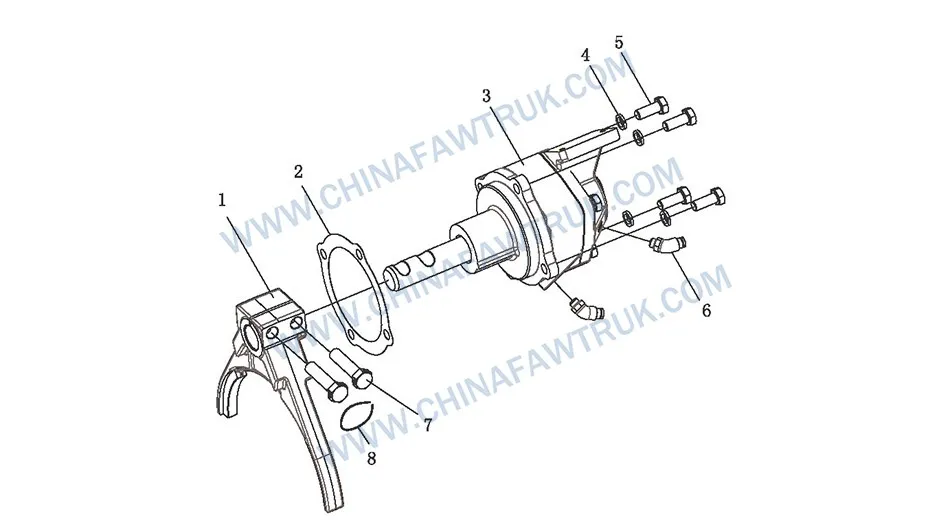

FAW Russian Sub-Box Gear-Range Cylinder Assembly

Pneumatic Core: O conjunto do cilindro

The primary actuator in this system is the Conjunto do cilindro – Subcaixa (Parte não. 1701640CA9K). This component converts compressed air energy into linear mechanical force. Dentro do Cilindro de faixa de engrenagens de sub-caixa russa FAW arquitetura, the cylinder is a double-acting unit, meaning it uses air pressure to extend (engage low range) and air pressure to retract (engage high range). This positive displacement design is crucial for the Russian market. Single-acting cylinders that rely on spring return often fail in the Arctic because the spring force cannot overcome the resistance of thickened transmission oil and stiffened seals at -40°C.

The internal piston of the Cilindro de faixa de engrenagens de sub-caixa russa FAW utilizes specialized low-temperature O-rings or lip seals. These seals are formulated from advanced elastomers that retain flexibility in extreme cold. A standard rubber seal would freeze hard, allowing air to bypass the piston. Esse “golpe” results in a lethargic shift or a failure to fully engage the gear, leading to the dreaded “false neutral” where the transmission disconnects the engine from the wheels—a dangerous situation on a downhill icy grade.

The housing of the cylinder is typically die-cast aluminum to resist corrosion from internal moisture. Compressed air systems in trucks naturally accumulate water condensate. If this water freezes inside the cylinder, it can lock the piston solid. O Cilindro de faixa de engrenagens de sub-caixa russa FAW is designed with internal geometry that minimizes water pockets, allowing condensate to be purged during operation cycles. This self-clearing capability is a vital reliability feature for vehicles operating in humid, freezing environments.

Tradução Mecânica: The Shift Fork

Connecting the pneumatic piston to the gear sliding sleeve is the Shift Fork – Sub-box Synchronizer (Parte não. 1701632FA0L). This component is the physical hand that moves the gears. No Cilindro de faixa de engrenagens de sub-caixa russa FAW sistema, the fork must be incredibly rigid. Any deflection or bending during the shift stroke results in partial engagement. Partial engagement causes the synchronizer teeth to grind and eventually strip, requiring a complete transmission overhaul.

The fork tips are fitted with wear pads, usually made from molybdenum-coated steel or a durable polymer. These pads ride in the groove of the spinning synchronizer sleeve. No Cilindro de faixa de engrenagens de sub-caixa russa FAW conjunto, these contact points are subjected to high friction and heat. The materials are selected to withstand this environment without galling. The fork itself is secured to the piston rod with precision alignment. Even a millimeter of misalignment can cause the fork to bind on the guide rail, freezing the range change mechanism.

The interaction between the fork and the cylinder is sealed by the Junta – Sub-box Cylinder (Parte não. 1701646-A7G). This gasket performs a dual function. Primarily, it seals the pneumatic chamber, preventing air loss. Secondarily, it may act as a shim to set the precise stroke length of the piston. No Cilindro de faixa de engrenagens de sub-caixa russa FAW, maintaining the correct stroke is essential to ensure the synchronizer is pushed fully into the “trancar” position but not so far that it presses against the gear face, creating drag and heat.

Lógica de Segurança: Wired Bolts and Vibration Control

The mounting of the shift fork to the shaft is a critical safety junction. O Cilindro de faixa de engrenagens de sub-caixa russa FAW assembly utilizes specialized Hexagon Head Bolt with Guide Neck (Parte não. CQ1711250S). These bolts feature a drilled hole in the head. This design is not for weight saving; it is for the application of Linha de bloqueio de fio de aço (Parte não. Q50516200).

In the high-vibration environment inside the transmission case, standard thread-locking compounds can fail due to the constant bath of hot oil. Mechanical locking via safety wire is the gold standard for reliability. The wire is threaded through the bolt heads in a specific pattern that creates tension in the tightening direction. If a bolt tries to loosen, the wire pulls it tighter. This ensures that the fork never comes loose from the actuation shaft within the Cilindro de faixa de engrenagens de sub-caixa russa FAW sistema.

External mounting of the cylinder housing is handled by Parafuso de cabeça hexagonal (Parte não. CQ1501025S) e Arruela elástica (Parte não. Q40310). These external fasteners must resist the corrosive spray of road salts. O Cilindro de faixa de engrenagens de sub-caixa russa FAW specification calls for zinc-nickel or similar high-grade plating on these bolts to prevent seizing. A seized bolt can turn a simple seal replacement into a nightmare task requiring drilling and tapping the aluminum housing.

Lógica de Fluxo: Elbow Joints and Air Delivery

Delivering the compressed air to the cylinder requires a robust interface. O Elbow Joint Assembly (Parte não. 1701670-A7G) is screwed into the cylinder ports. In the tight confines of the chassis, these elbows allow the rigid nylon air lines to approach the transmission at the correct angle without kinking. Kinked lines restrict airflow, slowing down the shift speed of the Cilindro de faixa de engrenagens de sub-caixa russa FAW.

The internal diameter of these fittings is calibrated to act as a flow control restrictor. If air rushes into the cylinder too fast, the shift can be violent, slamming the synchronizer rings together and causing wear. If too slow, the shift hangs. O Cilindro de faixa de engrenagens de sub-caixa russa FAW fittings modulate the airflow to provide a firm, positive shift action that is fast enough for performance but controlled enough for longevity.

Além disso, the threads on these fittings are typically coated with a pre-applied sealant. This prevents air leaks which are audible as a constant hiss. No Cilindro de faixa de engrenagens de sub-caixa russa FAW sistema, an air leak is not just an annoyance; it causes the system pressure to drop. If the pressure falls below a certain threshold (geralmente 6 bar), the range protection valve may prevent the shift from occurring at all, leaving the truck stuck in low range on a highway or high range in a pit.

Divisão de Componentes: 112. Sub-Box Gear Range Cylinder Assembly

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 1701632FA0L | Shift Fork – Sub-box Synchronizer | 1 |

| 2 | 1701646-A7G | Junta – Sub-box Cylinder | 1 |

| 3 | 1701640CA9K | Conjunto do cilindro – Subcaixa | 1 |

| 4 | Q40310 | Arruela elástica | 2 |

| 5 | CQ1501025S | Parafuso de cabeça hexagonal | 2 |

| 6 | 1701670-A7G | Elbow Joint Assembly | 2 |

| 7 | CQ1711250S | Hexagon Head Bolt with Guide Neck | 2 |

| 8 | Q50516200 | Linha de bloqueio de fio de aço | 2 |

Conclusão: The Pneumatic Switch

O Cilindro de faixa de engrenagens de sub-caixa russa FAW assembly is the definitive control interface for the range-splitting transmission. It seamlessly blends pneumatic power with mechanical precision to give the driver control over the vehicle’s torque output. Cada componente, from the cold-resistant piston seals to the wire-locked shift fork bolts, is engineered to prevent failure in the most demanding operational environments.

Para técnicos de transmissão, a mensagem é clara: respect the details. Reusing a crushed gasket or failing to install the safety wire on the fork bolts compromises the entire transmission. Ao utilizar o genuíno Cilindro de faixa de engrenagens de sub-caixa russa FAW parts and adhering to proper installation procedures, operators ensure that their fleet remains mobile, productive, and safe, regardless of the Siberian winter conditions.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.