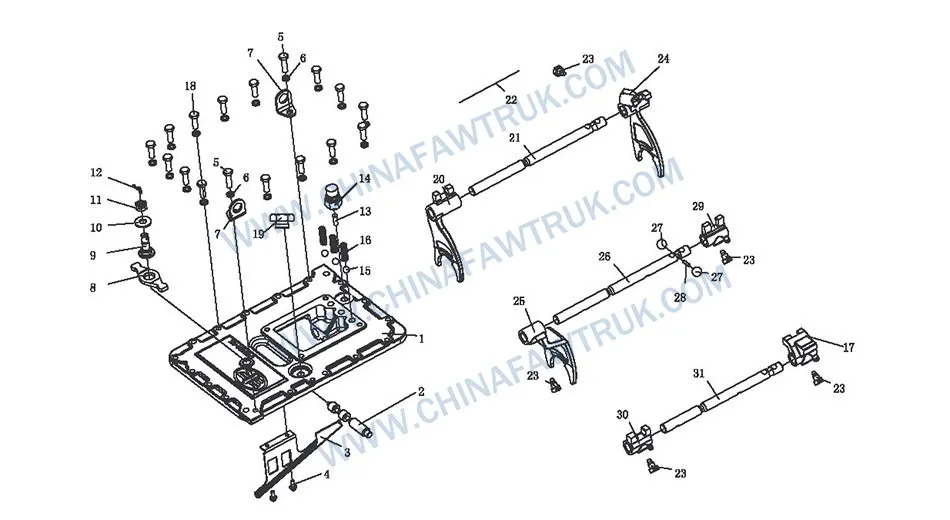

Assemblage du couvercle supérieur russe FAW: Orchestration 31 Composants stratégiques pour une sélection de vitesse de précision

Le Assemblage du couvercle supérieur russe FAW acts as the neurological command center for the CA3250P66K24L1TE5Z transmission. Situated atop the gearbox, this complex mechanism houses the shift rails, forks, and interlock systems that translate driver input into mechanical gear engagement. In the unforgiving Russian Arctic, where thick oil can impede movement, this assembly ensures crisp, reliable shifting. This guide dissects the 31 components defining its operation.

Assemblage du couvercle supérieur russe FAW

Housing Dynamics: The Upper Cover Shell

The structural foundation of the system is the Upper Cover (Partie no. 1702026-A1K). This casting is not merely a lid; it is a precision-machined chassis that aligns the shift rails with the gears below. Dans le Assemblage du couvercle supérieur russe FAW, the cover is typically cast from high-strength aluminum alloy or iron to provide rigidity while minimizing weight. The machining tolerances of the rail bores are critical. If the bores are too tight, the shift rails will bind when the metal contracts in -40°C temperatures. If too loose, the rails will wobble, leading to vague shifting and gear jump-out.

Integrated into the housing are features like the Oil Guide Groove (Partie no. 1702083-A7G). This component manages lubrication within the Assemblage du couvercle supérieur russe FAW. Since the upper cover sits above the oil bath, it relies on splash lubrication. The guide groove captures oil flung by the rotating gears and channels it directly onto the shift forks and rails. This ensures that the sliding mechanisms remain lubricated even during cold starts when the oil is viscous and sluggish, preventing metal-on-metal wear that would stiffen the shift action.

Securing the cover to the transmission case requires a multitude of fasteners, y compris 15 units of Boulon à tête hexagonale (Partie no. CQ1501035S) and another 15 units of Boulon à tête hexagonale (Partie no. CQ1501030S). The sheer number of bolts ensures a uniform clamping pressure on the gasket, sealing the transmission against water ingress—a vital feature for Russian dump trucks operating in muddy, melting snow. Le Lifting Eye (Partie no. 1702096-A7G) allows for safe removal of the heavy assembly during maintenance.

Mechanical Translation: Forks and Shafts

The core function of the Assemblage du couvercle supérieur russe FAW is executed by the shift forks. These include the Shift Fork Assy – 1st/Reverse (Partie no. 1702045-A1K), Fourche de changement de vitesse – 2nd/3rd Gear (Partie no. 1702037-A1K), et Fourche de changement de vitesse – 5th Gear (Partie no. 1702032-A1K). These forks are forged steel components designed to resist bending. When the driver moves the lever, these forks push the heavy sliding sleeves on the main shaft. Dans le Assemblage du couvercle supérieur russe FAW, the forks must be rigid enough to force the synchronizers to engage, even when the gear oil is cold and resisting motion.

The forks ride on precision-ground rails: Shift Fork Shaft – 1st/Reverse (Partie no. 1702041-A1K), Shift Fork Shaft – 2nd/3rd Gear (Partie no. 1702036-A1K), et Shift Fork Shaft – 4th/5th Gear (Partie no. 1702031-A1K). The surface finish of these shafts is mirror-smooth to minimize friction. Le Assemblage du couvercle supérieur russe FAW relies on the precise alignment of these shafts. Any warpage or bending would result in a “stuck gear” scenario.

Guiding the selection process are the Guide Block – 2nd/3rd Gear (Partie no. 1702038-A7G), Guide Block – 4th/5th Gear (Partie no. 1702033-A1K), et Guide Block – Inversion (Partie no. 1702034-A1K). These blocks interface with the shift finger of the gear lever. They are case-hardened to resist wear. If these blocks wear down, the gear lever develops excessive play or “pente,” making it difficult for the driver to find the correct gate. The durability of the Assemblage du couvercle supérieur russe FAW guide blocks ensures positive, confident shifting for the vehicle’s lifespan.

Safety Logic: Interlocks and Detents

Preventing catastrophic double-gear engagement is the job of the interlock system within the Assemblage du couvercle supérieur russe FAW. This system uses Interlock Steel Ball (Partie no. 1702063-A7G) et Goupille de verrouillage (Partie no. 1702064-A7G). When one shift rail moves to engage a gear, it pushes a steel ball sideways, locking the other rails in the neutral position. This mechanical logic is fail-safe. It physically prevents the transmission from being in two gears at once, which would instantly lock the wheels and destroy the driveline.

To ensure the transmission stays in the selected gear, le Assemblage du couvercle supérieur russe FAW employs a detent mechanism using Bille d'acier (Partie no. Q967165) et Self-locking Spring (Partie no. 1702061AA4P). The spring pushes the ball into notches machined on the shift rails. This provides the tactile “cliquez” the driver feels when a gear engages. More importantly, it holds the rail in place against the vibrations of the road. Without strong detents, a dump truck bouncing over mining ruts would constantly pop out of gear.

Le Reverse Light Switch Assembly (Partie no. 3729100-71UN) and its actuation pin, Épingle – Reverse Light Switch (Partie no. 1702086-A7G), are also integrated here. This ensures that the reverse lights and backup alarm activate only when the reverse rail is fully moved. Le Assemblage du couvercle supérieur russe FAW integrates this safety signaling directly into the mechanical action of the shift, assurer la fiabilité.

Assembly Security: Wired for Reliability

Inside the transmission, a loose bolt is a disaster. Le Assemblage du couvercle supérieur russe FAW secures the shift forks to the rails using Vis de fixation (Partie no. 1702056-A7G). These screws are not just tightened; they are mechanically locked using Steel Wire Lock Line (Partie no. Q50512250). The wire is threaded through the heads of the screws in pairs, creating a tension network that physically prevents rotation.

This wire-locking technique is essential for the Assemblage du couvercle supérieur russe FAW. Chemical thread lockers can degrade in hot transmission oil. Safety wire provides a permanent, visual guarantee of security. It ensures that the forks never slip on the rails, preserving the precise alignment required for synchronization.

External fasteners like the Boulon de bride hexadécimal (Partie no. Q1840616S) et le Hex Slotted Flat Nut (Partie no. CQ38714) secured with a Goupille fendue (Partie no. Q5003025) demonstrate the comprehensive approach to security. De la Reversing Arm (Partie no. 1702078-A1K) to the internal rails, every component of the Assemblage du couvercle supérieur russe FAW is locked down to survive the punishing vibration profile of a heavy-duty diesel engine.

Répartition des composants: 113. Upper Cover Assembly

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | 1702026-A1K | Upper Cover | 1 |

| 2 | 1702076-A7G | Air Valve Shaft | 1 |

| 3 | 1702083-A7G | Oil Guide Groove | 1 |

| 4 | Q1840616S | Boulon de bride hexadécimal | 2 |

| 5 | CQ1501035S | Boulon de tête hexagonale | 15 |

| 6 | Q40310 | Rondelle à ressort | 17 |

| 7 | 1702096-A7G | Lifting Eye | 2 |

| 8 | 1702078-A1K | Reversing Arm | 1 |

| 9 | 1702073-14 | Reversing Shaft – 5ème & 6th Gear | 1 |

| 10 | 1702076-14 | Machine à laver | 1 |

| 11 | CQ38714 | Hex Slotted Flat Nut | 1 |

| 12 | Q5003025 | Goupille fendue | 1 |

| 13 | 1702086-A7G | Épingle – Reverse Light Switch | 1 |

| 14 | 3729100-71UN | Reverse Light Switch Assembly | 1 |

| 15 | Q967165 | Bille d'acier | 3 |

| 16 | 1702061AA4P | Self-locking Spring | 3 |

| 17 | 1702033-A1K | Guide Block – 4th/5th Gear | 1 |

| 18 | CQ1501030S | Boulon de tête hexagonale | 15 |

| 19 | CQ61718 | Hex Head Plug | 1 |

| 20 | 1702032-A1K | Fourche de changement de vitesse – 5th Gear | 1 |

| 21 | 1702041-A1K | Shift Fork Shaft – 1st/Reverse | 1 |

| 22 | Q50512250 | Steel Wire Lock Line | 5 |

| 23 | 1702056-A7G | Vis de fixation | 5 |

| 24 | 1702045-A1K | Shift Fork Assy – 1st/Reverse | 1 |

| 25 | 1702037-A1K | Fourche de changement de vitesse – 2nd/3rd Gear | 1 |

| 26 | 1702036-A1K | Shift Fork Shaft – 2nd/3rd Gear | 1 |

| 27 | 1702063-A7G | Interlock Steel Ball | 2 |

| 28 | 1702064-A7G | Goupille de verrouillage | 2 |

| 29 | 1702038-A7G | Guide Block – 2nd/3rd Gear | 1 |

| 30 | 1702034-A1K | Guide Block – Inversion | 1 |

| 31 | 1702031-A1K | Shift Fork Shaft – 4th/5th Gear | 1 |

Conclusion: The Brain of the Transmission

Le Assemblage du couvercle supérieur russe FAW is the command center of the transmission, translating human intent into mechanical action. By organizing the shift rails, ensuring precise detents, and physically preventing gear conflicts via interlocks, this assembly defines the drivability of the truck. Its robust construction and specialized lubrication management ensure that drivers can select the right gear every time, even in the freezing depths of the Russian winter.

For transmission technicians, rebuilding this assembly requires a clean-room approach. Small contaminants can jam the interlock balls or score the shift rails. En outre, the correct re-installation of the safety wire is critical. By using the genuine Assemblage du couvercle supérieur russe FAW composants, operators guarantee that their transmission remains a reliable, precise instrument of power delivery, protecting the entire drivetrain from operator error and environmental stress.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.