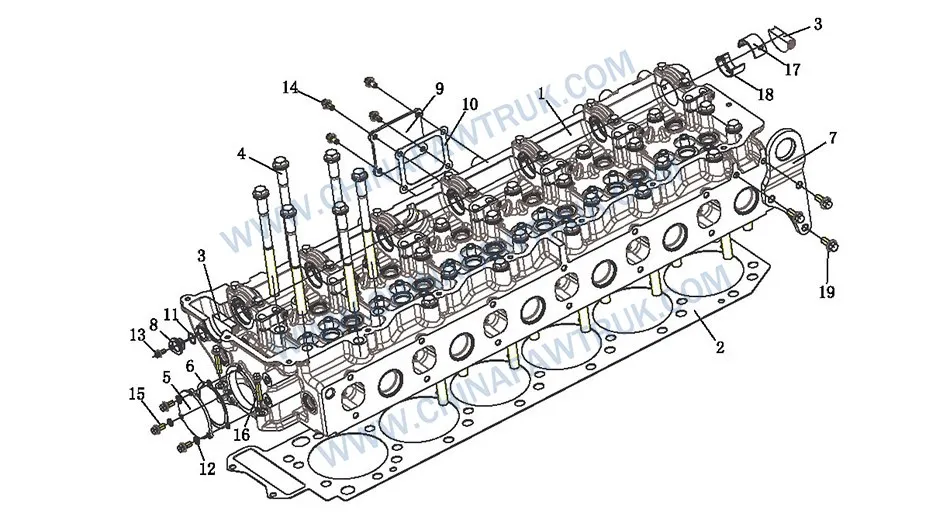

Ensemble de culasse russe FAW2: 19 Vital Components Engineered for Arctic Seal Integrity

Le Ensemble de culasse russe FAW2 focuses on the critical sealing and fastening architecture of the CA3250P66K24L1TE5Z engine. Unlike the main casting, this sub-assembly manages the gaskets, boulons, and sensor covers required to maintain compression. It is the final defense against fluid leaks in the harsh freeze-thaw cycles of the Russian Federation.

Ensemble de culasse russe FAW2

Sealing Architecture: Gaskets and O-Rings

The core mission of the Ensemble de culasse russe FAW2 is containment. Le principal obstacle est le Ensemble de joint de culasse (Partie no. 1003020-81D).

Dans l'Arctique russe, engines undergo extreme contraction overnight. A standard gasket would shear under this movement. This specific component uses a Multi-Layer Steel (MLS) conception.

The layers are coated with a specialized fluoro-elastomer. This allows the head and block to move independently on a microscopic level while maintaining a gas-tight seal for peak combustion pressure.

Preventing oil leaks at the rear of the cam valley is the Cylinder Head Seal Half Circle (Partie no. 1003042-81D). This semi-circular plug fills the machining bore left by the line-boring process.

It is crafted from a heat-resistant rubber that does not shrink after years of exposure to 100°C engine oil. Shrinkage here would result in a messy oil leak down the back of the engine block.

Fluid systems are further secured by the Joint torique pneumatique hydraulique en caoutchouc (Partie no. CQ7341170A). This seal handles auxiliary fluid connections.

FAW specifies a high-grade compound for this O-ring to prevent “explosive decompression” or swelling. Swollen seals can block critical oil passages, starving downstream components in the Ensemble de culasse russe FAW2.

Force de serrage: Bolts and Protective Covers

The integrity of the head gasket relies entirely on the Boulon de culasse (Partie no. 1003047-53D). Il y a 26 of these bolts in the assembly, and they are engineered as Torque-to-Yield (ATS) attaches.

When tightened to spec, these bolts permanently stretch into their elastic region. Cela crée un “spring-like” clamping force that accommodates the thermal expansion of the Ensemble de culasse russe FAW2 without loosening.

Because they stretch permanently, these bolts are single-use items. Reusing them is a critical error that will lead to a blown head gasket within kilometers of an overhaul.

To protect the internal gear train, le système utilise le Plaque de couverture de chambre d'engrenage (Partie no. 1003051-81D). This stamped steel cover prevents road grit and ice from entering the timing gears.

It is sealed with a dedicated Joint – Plaque de couverture de chambre d'engrenage (Partie no. 1003052-81D). In Russian operations, salt spray is a major concern; this gasket prevents corrosive brine from seeping into the gear housing.

De la même manière, the intake system is sealed by the Plaque de recouvrement du collecteur d'admission (Partie no. 1008018-81D) and its corresponding Joint (Partie no. 1008019-81D). These ensure that the turbocharger’s boost pressure reaches the cylinders rather than leaking into the atmosphere.

Precision Support: Bearings and Sensor Interfaces

Supporting the rotating camshaft are the bearing shells: Camshaft Upper Tile/Bearing Shell (Partie no. 1003072-81D) et Camshaft Lower Tile/Bearing Shell (Partie no. 1003073-81D).

These split bearings are lined with a sacrificial babbitt material. This soft lining allows any microscopic debris in the oil to embed itself into the bearing wall rather than scoring the camshaft journal.

This feature is vital in the Ensemble de culasse russe FAW2 during cold starts, where oil filter bypass valves may open, allowing unfiltered oil to circulate briefly.

Engine timing data is managed via the Camshaft Gear Sensor Cover Assembly (Partie no. 1003090-81D). This rigid cover provides a stable mounting platform for the phase sensor.

Vibration at this point would cause “signal noise,” confusing the ECU regarding the camshaft’s position. This leads to erratic injection timing and poor fuel economy in the Ensemble de culasse russe FAW2.

Small details matter. Le Rondelle en cuivre (Partie no. Q / WC3403-94) is used on banjo connections. It crushes to form a perfect metal-to-metal seal, essential for leak-free hydraulic lines in sub-zero temperatures.

Liste de répartition des composants

The table below details the official Bill of Materials (Nomenclature) pour le Ensemble de culasse russe FAW2. Fleet managers should verify these part numbers during top-end overhauls to ensure full compatibility with the CA3250P66K24L1TE5Z.

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

1003010-81D |

Ensemble de culasse |

1 |

| 2 |

1003020-81D |

Ensemble de joint de culasse |

1 |

| 3 |

1003042-81D |

Cylinder Head Seal Half Circle |

2 |

| 4 |

1003047-53D |

Boulon de culasse (Style Map) |

26 |

| 5 |

1003051-81D |

Plaque de couverture de chambre d'engrenage |

1 |

| 6 |

1003052-81D |

Joint – Plaque de couverture de chambre d'engrenage |

1 |

| 7 |

1003058-81D |

Front Lifting Eye – Cylinder Head |

1 |

| 8 |

1003090-81D |

Camshaft Gear Sensor Cover Assembly |

1 |

| 9 |

1008018-81D |

Plaque de recouvrement du collecteur d'admission |

1 |

| 10 |

1008019-81D |

Joint – Plaque de recouvrement du collecteur d'admission |

1 |

| 11 |

CQ7341170A |

Joint torique pneumatique hydraulique en caoutchouc |

1 |

| 12 |

Q / WC3403-94 (8X14) |

Rondelle en cuivre |

3 |

| 13 |

Q1840612 |

Boulon à bride hexagonale (Grossier/Standard) |

1 |

| 14 |

Q1840612 |

Boulon à bride hexagonale (Grossier/Standard) |

4 |

| 15 |

Q1840816 |

Boulon à bride hexagonale (Grossier/Standard) |

3 |

| 16 |

Q1840845 |

Boulon à bride hexagonale (Grossier/Standard) |

2 |

| 17 |

1003072-81D |

Camshaft Upper Tile/Bearing Shell |

7 |

| 18 |

1003073-81D |

Camshaft Lower Tile/Bearing Shell |

7 |

| 19 |

Q1841025 |

Boulon à bride hexagonale (Grossier/Standard) |

3 |

Diagnostic Indicators for Sealing Failures

Effective diagnosis of the Ensemble de culasse russe FAW2 often starts with the coolant. If you detect oil in the expansion tank, le Ensemble de joint de culasse may be compromised near the high-pressure oil feed.

Inversement, white exhaust smoke indicates coolant entering the cylinder. Dans des conditions arctiques, this is often due to the reuse of old Boulon de culasse fasteners which have lost their clamping yield.

Pay close attention to the Front Lifting Eye – Cylinder Head. While structural, loose bolts here can induce vibration.

This vibration can propagate stress cracks into the head casting. Regularly checking the torque on these accessible bolts is a simple preventative measure.

Inspectez le Camshaft Gear Sensor Cover Assembly for external oil leaks. A leak here can foul the cam sensor.

This leads to hard starting in cold weather. Remplacez toujours le Joint – Plaque de couverture de chambre d'engrenage whenever this cover is removed.

Conclusion: The Importance of Genuine Seals

Le Ensemble de culasse russe FAW2 is the unsung hero of the engine’s power stroke. It ensures that the pressures created by combustion are harnessed, not wasted.

Chaque composant, de la Cylinder Head Seal Half Circle to the main gasket, is engineered for specific thermal expansion rates.

Pour les exploitants de flotte, the choice is clear. Genuine FAW parts provide the assurance of a perfect fit and long-term durability. Using inferior gaskets in the Ensemble de culasse russe FAW2 is a gamble that inevitably leads to downtime in the unforgiving Russian climate.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.