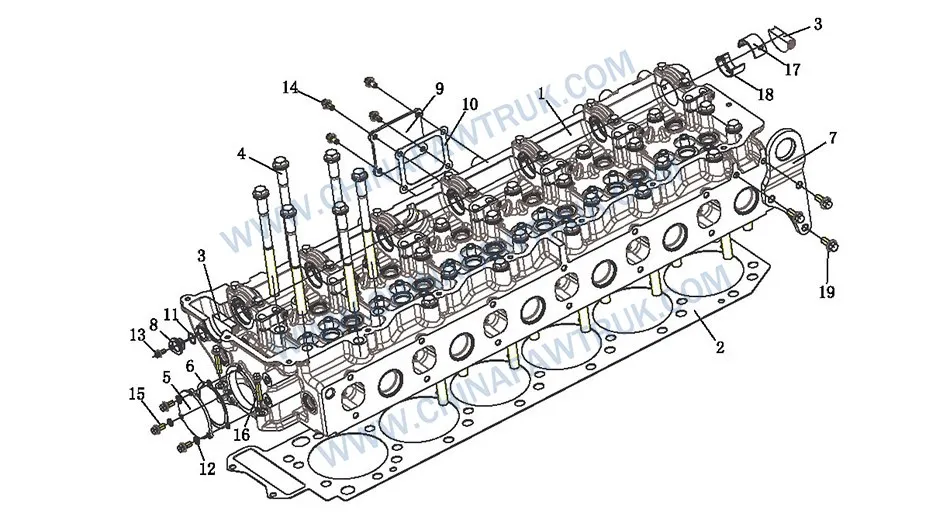

Conjunto de cabeçote russo FAW2: 19 Vital Components Engineered for Arctic Seal Integrity

O Conjunto de cabeçote russo FAW2 focuses on the critical sealing and fastening architecture of the CA3250P66K24L1TE5Z engine. Unlike the main casting, this sub-assembly manages the gaskets, parafusos, and sensor covers required to maintain compression. It is the final defense against fluid leaks in the harsh freeze-thaw cycles of the Russian Federation.

Conjunto de cabeçote russo FAW2

Sealing Architecture: Gaskets and O-Rings

The core mission of the Conjunto de cabeçote russo FAW2 is containment. A principal barreira é a Conjunto da junta da cabeça do cilindro (Parte não. 1003020-81D).

No Ártico Russo, engines undergo extreme contraction overnight. A standard gasket would shear under this movement. This specific component uses a Multi-Layer Steel (MLS) projeto.

The layers are coated with a specialized fluoro-elastomer. This allows the head and block to move independently on a microscopic level while maintaining a gas-tight seal for peak combustion pressure.

Preventing oil leaks at the rear of the cam valley is the Cylinder Head Seal Half Circle (Parte não. 1003042-81D). This semi-circular plug fills the machining bore left by the line-boring process.

It is crafted from a heat-resistant rubber that does not shrink after years of exposure to 100°C engine oil. Shrinkage here would result in a messy oil leak down the back of the engine block.

Fluid systems are further secured by the Vedação de borracha O-ring pneumática hidráulica (Parte não. CQ7341170A). This seal handles auxiliary fluid connections.

FAW specifies a high-grade compound for this O-ring to prevent “explosive decompression” or swelling. Swollen seals can block critical oil passages, starving downstream components in the Conjunto de cabeçote russo FAW2.

Força de fixação: Bolts and Protective Covers

The integrity of the head gasket relies entirely on the Cylinder Head Bolt (Parte não. 1003047-53D). Há 26 of these bolts in the assembly, and they are engineered as Torque-to-Yield (TTY) fixadores.

When tightened to spec, these bolts permanently stretch into their elastic region. Isto cria um “spring-like” clamping force that accommodates the thermal expansion of the Conjunto de cabeçote russo FAW2 without loosening.

Because they stretch permanently, these bolts are single-use items. Reusing them is a critical error that will lead to a blown head gasket within kilometers of an overhaul.

To protect the internal gear train, o sistema usa o Placa de cobertura da câmara de engrenagens (Parte não. 1003051-81D). This stamped steel cover prevents road grit and ice from entering the timing gears.

It is sealed with a dedicated Junta – Placa de cobertura da câmara de engrenagens (Parte não. 1003052-81D). In Russian operations, salt spray is a major concern; this gasket prevents corrosive brine from seeping into the gear housing.

De forma similar, the intake system is sealed by the Intake Manifold Cover Plate (Parte não. 1008018-81D) e seu correspondente Junta (Parte não. 1008019-81D). These ensure that the turbocharger’s boost pressure reaches the cylinders rather than leaking into the atmosphere.

Precision Support: Bearings and Sensor Interfaces

Supporting the rotating camshaft are the bearing shells: Camshaft Upper Tile/Bearing Shell (Parte não. 1003072-81D) e Camshaft Lower Tile/Bearing Shell (Parte não. 1003073-81D).

These split bearings are lined with a sacrificial babbitt material. This soft lining allows any microscopic debris in the oil to embed itself into the bearing wall rather than scoring the camshaft journal.

This feature is vital in the Conjunto de cabeçote russo FAW2 during cold starts, where oil filter bypass valves may open, allowing unfiltered oil to circulate briefly.

Engine timing data is managed via the Camshaft Gear Sensor Cover Assembly (Parte não. 1003090-81D). This rigid cover provides a stable mounting platform for the phase sensor.

Vibration at this point would cause “signal noise,” confusing the ECU regarding the camshaft’s position. This leads to erratic injection timing and poor fuel economy in the Conjunto de cabeçote russo FAW2.

Small details matter. O Lavadora de cobre (Parte não. Q/WC3403-94) is used on banjo connections. It crushes to form a perfect metal-to-metal seal, essential for leak-free hydraulic lines in sub-zero temperatures.

Lista detalhada de componentes

The table below details the official Bill of Materials (BOM) para o Conjunto de cabeçote russo FAW2. Fleet managers should verify these part numbers during top-end overhauls to ensure full compatibility with the CA3250P66K24L1TE5Z.

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 |

1003010-81D |

Conjunto da cabeça do cilindro |

1 |

| 2 |

1003020-81D |

Conjunto da junta da cabeça do cilindro |

1 |

| 3 |

1003042-81D |

Cylinder Head Seal Half Circle |

2 |

| 4 |

1003047-53D |

Cylinder Head Bolt (Style Map) |

26 |

| 5 |

1003051-81D |

Placa de cobertura da câmara de engrenagens |

1 |

| 6 |

1003052-81D |

Junta – Placa de cobertura da câmara de engrenagens |

1 |

| 7 |

1003058-81D |

Front Lifting Eye – Cabeça de cilindro |

1 |

| 8 |

1003090-81D |

Camshaft Gear Sensor Cover Assembly |

1 |

| 9 |

1008018-81D |

Intake Manifold Cover Plate |

1 |

| 10 |

1008019-81D |

Junta – Intake Manifold Cover Plate |

1 |

| 11 |

CQ7341170A |

Vedação de borracha O-ring pneumática hidráulica |

1 |

| 12 |

Q/WC3403-94 (8X14) |

Lavadora de cobre |

3 |

| 13 |

Q1840612 |

Parafuso de flange hexagonal (Grosso/Padrão) |

1 |

| 14 |

Q1840612 |

Parafuso de flange hexagonal (Grosso/Padrão) |

4 |

| 15 |

Q1840816 |

Parafuso de flange hexagonal (Grosso/Padrão) |

3 |

| 16 |

Q1840845 |

Parafuso de flange hexagonal (Grosso/Padrão) |

2 |

| 17 |

1003072-81D |

Camshaft Upper Tile/Bearing Shell |

7 |

| 18 |

1003073-81D |

Camshaft Lower Tile/Bearing Shell |

7 |

| 19 |

Q1841025 |

Parafuso de flange hexagonal (Grosso/Padrão) |

3 |

Diagnostic Indicators for Sealing Failures

Effective diagnosis of the Conjunto de cabeçote russo FAW2 often starts with the coolant. If you detect oil in the expansion tank, o Conjunto da junta da cabeça do cilindro may be compromised near the high-pressure oil feed.

Por outro lado, white exhaust smoke indicates coolant entering the cylinder. Nas condições do Ártico, this is often due to the reuse of old Cylinder Head Bolt fasteners which have lost their clamping yield.

Pay close attention to the Front Lifting Eye – Cabeça de cilindro. While structural, loose bolts here can induce vibration.

This vibration can propagate stress cracks into the head casting. Regularly checking the torque on these accessible bolts is a simple preventative measure.

Inspecione o Camshaft Gear Sensor Cover Assembly for external oil leaks. A leak here can foul the cam sensor.

This leads to hard starting in cold weather. Sempre substitua o Junta – Placa de cobertura da câmara de engrenagens whenever this cover is removed.

Conclusão: The Importance of Genuine Seals

O Conjunto de cabeçote russo FAW2 is the unsung hero of the engine’s power stroke. It ensures that the pressures created by combustion are harnessed, not wasted.

Cada componente, do Cylinder Head Seal Half Circle to the main gasket, is engineered for specific thermal expansion rates.

Para operadores de frota, the choice is clear. Genuine FAW parts provide the assurance of a perfect fit and long-term durability. Using inferior gaskets in the Conjunto de cabeçote russo FAW2 is a gamble that inevitably leads to downtime in the unforgiving Russian climate.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.