Unité de condensateur russe FAW: Garde 4 Composants stratégiques pour un rejet thermique ultime dans l'Arctique

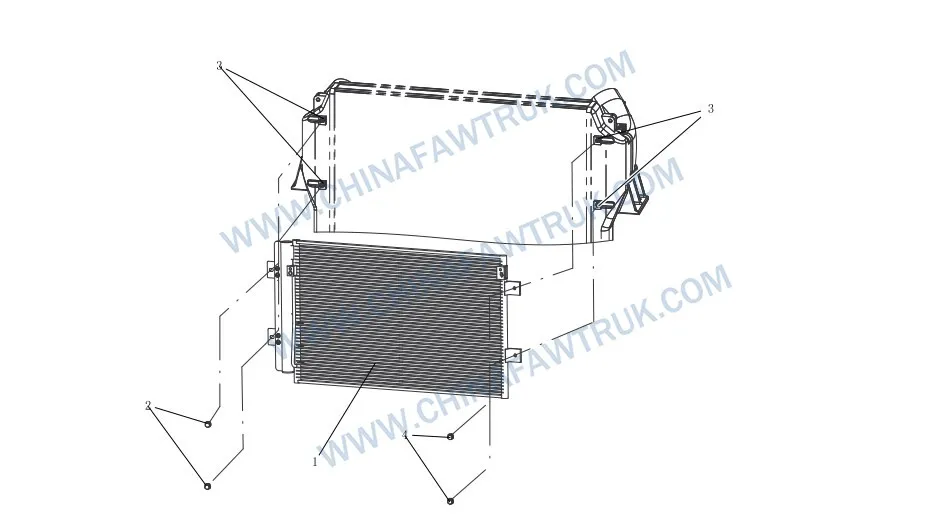

Le Unité de condensateur russe FAW is the essential heat-dissipation module within the climate control system of the Camion-benne FAW CA3250P66K24L1TE5Z. Situé à l'avant du véhicule, this assembly handles the critical function of rejecting heat absorbed from the cabin air. In the extreme temperature swings of the Russian Arctic, the efficiency of the Unité de condensateur russe FAW directly determines the cooling performance in summer and the dehumidification capability vital for defrosting in winter. This module integrates high-efficiency heat exchange technology with a robust mounting system to ensure operational reliability, faire le Unité de condensateur russe FAW a non-negotiable safety component.

Unité de condensateur russe FAW

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

8105010-13A-C00 |

Assemblage du condensateur |

1 |

| 2 |

CQ1460820 |

Boulon combiné |

2 |

| 3 |

CQ34008 |

Écrou hexagonal |

4 |

| 4 |

CQ1460825 |

Boulon combiné |

2 |

Thermal Engineering: The Condenser Assembly Core

The primary component driving the efficiency of the Unité de condensateur russe FAW est le Assemblage du condensateur (Partie no. 8105010-13A-C00). This heat exchanger is responsible for converting high-pressure, superheated refrigerant vapor back into a high-pressure liquid state. Le Assemblage du condensateur utilizes a parallel flow design, which maximizes heat transfer efficiency. This design is preferred in heavy-duty vehicles because it performs better under the varying airflow conditions experienced during low-speed, high-load mining operations in the Russian Arctic.

The material science of the Assemblage du condensateur is crucial for its longevity within the Unité de condensateur russe FAW système. It is constructed entirely of specialized aluminum alloys with micro-port tubes and louvered fins. This construction ensures a maximum surface area-to-volume ratio. The external coating of the Assemblage du condensateur is treated for corrosion resistance against the highly corrosive road salts and chemical de-icers that are commonly used in the Russian North. This protection prevents the rapid decay of the delicate aluminum fins, which would otherwise compromise heat rejection capabilities.

Le montage du Assemblage du condensateur is designed to protect it from thermal shock. Rapid temperature swings in the Arctic can cause expansion and contraction fatigue. The surrounding structure of the Unité de condensateur russe FAW allows for slight, controlled movement of the core, minimizing stress on the braze joints that connect the tubes and fins. Tout échec dans le Assemblage du condensateur braze joints would lead to an immediate refrigerant leak, shutting down the AC system entirely, which is a major safety concern in extreme climates.

Le Unité de condensateur russe FAW also features internal design elements that address the need for sub-cooling. After the refrigerant condenses into liquid, it must be cooled further to maximize system efficiency. The micro-channel design of the Assemblage du condensateur ensures that the refrigerant spends sufficient time in the unit to achieve optimal sub-cooling, providing colder air at the evaporator core. This high-efficiency operation allows the Unité de condensateur russe FAW to perform its dehumidification role effectively, which is vital for maintaining a clear, frost-free windshield in winter conditions.

Fastening Architecture: Boulons combinés

L'intégrité structurelle du Unité de condensateur russe FAW mounting is reliant on the specialized fasteners: le Boulon combiné (Partie no. CQ1460820) and the slightly longer Boulon combiné (Partie no. CQ1460825). Le terme “Boulon combiné” signifies that these high-tensile fasteners include pre-assembled captive washers, typically a flat washer and a spring lock washer. This is a critical quality control feature for the Unité de condensateur russe FAW installation. It eliminates the risk of mechanics omitting the anti-vibration washer, which would inevitably lead to loosening.

The two different lengths of the Boulon combiné (CQ1460820 et CQ1460825) are specified to accommodate the varying thicknesses of the structural brackets and mounting points on the chassis. Precision in length is essential; using an incorrect length can either cause the bolt to bottom out before reaching the required torque or result in insufficient thread engagement, compromising the load-bearing capacity. The careful selection of these fasteners ensures the entire Unité de condensateur russe FAW remains rigidly fixed despite the extreme vibration of the dump truck’s engine and drivetrain.

The surface treatment of the Boulon combiné is also engineered for the corrosive Arctic environment. They feature a high-performance coating—often zinc-flake or Dacromet—that is far superior to standard zinc plating. This coating ensures that the threads do not seize due to oxidation caused by road salt exposure, permettant à la Unité de condensateur russe FAW to be easily removed for radiator service or replacement, maintaining vehicle serviceability and reducing fleet downtime.

The spring washer element within the Boulon combiné is essential for dynamic load security. The constant jarring and shaking inherent in mining operations can slowly back out a standard bolt. The spring action provides continuous, reactive tension, maintaining the critical preload force that keeps the Assemblage du condensateur brackets locked against the frame. Cela garantit que le Unité de condensateur russe FAW mounting maintains its integrity, preventing rattling and potential fatigue damage to the core’s refrigerant lines.

Load Distribution and Locking Mechanisms

Complementing the bolt assembly is the Écrou hexagonal (Partie no. CQ34008). Four of these nuts are used to anchor the Unité de condensateur russe FAW mounting brackets to the chassis, typically in through-hole applications where the vehicle structure cannot be threaded. These nuts are specified to match the high tensile strength of the Boulon combiné (Partie no. CQ1460820 et CQ1460825), ensuring that the weak point is not the fastening system but the intended sheer zone. This strength is vital for absorbing the energy of minor frontal impacts common in pit operations.

The high torque applied to the Écrou hexagonal creates the compressive force needed to hold the Assemblage du condensateur mounting structure firmly against the frame. This rigidity prevents the entire unit from vibrating excessively, which could otherwise damage the delicate aluminum fins of the Assemblage du condensateur. The stability provided by the secure mounting of the Unité de condensateur russe FAW is essential for maximizing the efficiency of the parallel flow design, as uncontrolled movement would disrupt the airflow across the heat exchanger.

Maintenance protocols stress the importance of using only genuine Écrou hexagonal et Boulon combiné composants. Substituting them with low-grade hardware compromises the system’s ability to withstand the thermal and vibrational stress of the Arctic environment. The integrity of the fastening ensures that the Unité de condensateur russe FAW maintains its precise alignment with the radiator and the cooling fan shroud, which is necessary for efficient heat rejection. Misalignment, caused by loose fasteners, significantly reduces the performance of the climate control system.

En outre, the anti-corrosion coating on the Écrou hexagonal prevents galling—the welding of the bolt threads to the nut threads under high pressure and vibration. Galling would make future disassembly for maintenance impossible. Le revêtement spécialisé sur le Unité de condensateur russe FAW hardware ensures that the connection remains strong yet releasable, providing fleet mechanics with the serviceability they require to operate the CA3250 dump truck efficiently in harsh Russian conditions, protecting the reliability of the Unité de condensateur russe FAW.

Refrigerant Dynamics and Environmental Protection

L'objectif premier du Assemblage du condensateur au sein de Unité de condensateur russe FAW is phase conversion. High-pressure refrigerant gas enters the unit and rejects its heat to the atmosphere, turning back into a liquid state. This efficiency is measured in the sub-cooling achieved within the Assemblage du condensateur. The design features multiple passes within the core, maximizing the time the refrigerant spends in contact with the cooled fins. The greater the sub-cooling, the higher the efficiency of the entire refrigeration cycle, leading to quicker cabin cool-down.

The robust mounting of the Unité de condensateur russe FAW is also vital for protecting the refrigerant lines. The high-pressure tubing connecting the compressor to the Assemblage du condensateur is subject to extreme pulsing and vibration. Secure fastening with the Boulon combiné (CQ1460820 et CQ1460825) et le Écrou hexagonal prevents excessive movement of the unit, which could fatigue the refrigerant lines and cause catastrophic leaks. A simple failure in the mounting system can lead to a complete loss of refrigerant, rendering the AC system inoperable immediately.

The forward positioning of the Unité de condensateur russe FAW makes it highly vulnerable to impact damage. The aluminum fins are thin and easily damaged by stones and debris. The structural brackets and mounting bolts, sécurisé par le Écrou hexagonal, provide a rigid perimeter defense. Using the specified Assemblage du condensateur ensures that the core itself has sufficient strength to resist minor damage without immediate leakage. This frontal armor function is a key consideration for dump trucks operating in open-pit environments where flying debris is a constant threat.

Maintenance checks should specifically target the torque applied to the Boulon combiné and the condition of the mounting brackets. Any evidence of looseness suggests vibration has been allowed to act on the frame, risking the integrity of the Assemblage du condensateur. Le Unité de condensateur russe FAW is a high-cost component; donc, preventative maintenance on the low-cost fasteners (le Boulon combiné et le Écrou hexagonal) provides a massive return on investment by preventing core replacement.

Conclusion: Protecting Cabin Climate and Lifespan

Le Unité de condensateur russe FAW assembly is a vital system that goes beyond simple comfort, directly impacting driver safety and asset lifespan. En intégrant le haut rendement Assemblage du condensateur with a meticulously engineered fastening system—relying on multiple Boulon combiné variants and the robust security of the Écrou hexagonal—FAW ensures maximum thermal rejection and structural integrity. This module is built to endure the extreme cold, heavy vibration, and corrosive elements of the Russian environment.

For fleet managers of the CA3250 dump truck, adhering to the specified bill of materials is mandatory. Substituting any component, particularly the fasteners or the Assemblage du condensateur, risks catastrophic AC system failure. By utilizing genuine FAW parts, especially the corrosion-resistant Boulon combiné et Écrou hexagonal, maintenance teams guarantee the continued reliability of the Unité de condensateur russe FAW, ensuring the truck remains a safe and productive piece of machinery in the world’s most unforgiving climates.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.