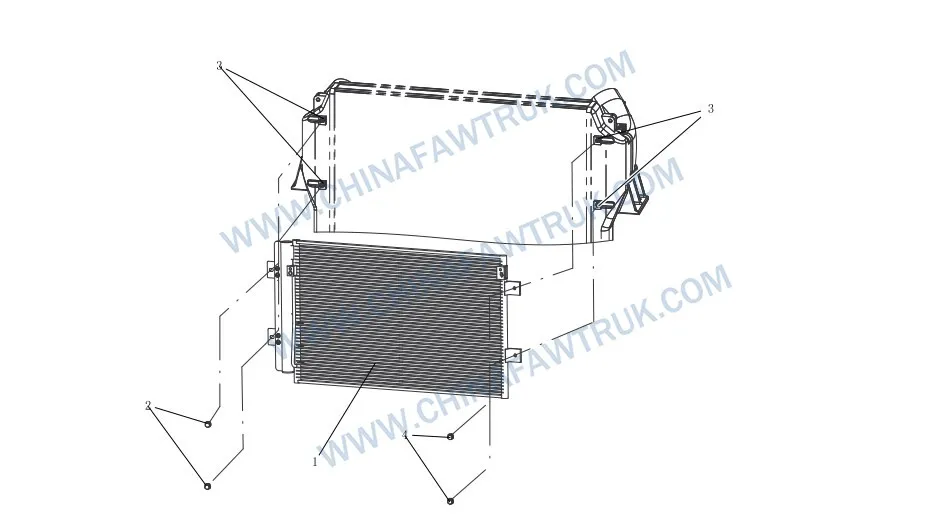

Unidad condensadora rusa FAW: custodiando 4 Componentes estratégicos para el rechazo térmico definitivo en el Ártico

El Unidad condensadora rusa FAW is the essential heat-dissipation module within the climate control system of the Camión volquete FAW CA3250P66K24L1TE5Z. Ubicado en la parte delantera del vehículo, this assembly handles the critical function of rejecting heat absorbed from the cabin air. In the extreme temperature swings of the Russian Arctic, the efficiency of the Unidad condensadora rusa FAW directly determines the cooling performance in summer and the dehumidification capability vital for defrosting in winter. This module integrates high-efficiency heat exchange technology with a robust mounting system to ensure operational reliability, haciendo el Unidad condensadora rusa FAW a non-negotiable safety component.

Unidad condensadora rusa FAW

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 |

8105010-13A-C00 |

Ensamblaje del condensador |

1 |

| 2 |

CQ1460820 |

Perno combinado |

2 |

| 3 |

CQ34008 |

Tuerca hexagonal |

4 |

| 4 |

CQ1460825 |

Perno combinado |

2 |

Thermal Engineering: The Condenser Assembly Core

The primary component driving the efficiency of the Unidad condensadora rusa FAW es el Ensamblaje del condensador (Número de pieza. 8105010-13A-C00). This heat exchanger is responsible for converting high-pressure, superheated refrigerant vapor back into a high-pressure liquid state. El Ensamblaje del condensador utilizes a parallel flow design, which maximizes heat transfer efficiency. This design is preferred in heavy-duty vehicles because it performs better under the varying airflow conditions experienced during low-speed, high-load mining operations in the Russian Arctic.

The material science of the Ensamblaje del condensador is crucial for its longevity within the Unidad condensadora rusa FAW sistema. It is constructed entirely of specialized aluminum alloys with micro-port tubes and louvered fins. This construction ensures a maximum surface area-to-volume ratio. The external coating of the Ensamblaje del condensador is treated for corrosion resistance against the highly corrosive road salts and chemical de-icers that are commonly used in the Russian North. This protection prevents the rapid decay of the delicate aluminum fins, which would otherwise compromise heat rejection capabilities.

El montaje de la Ensamblaje del condensador is designed to protect it from thermal shock. Los rápidos cambios de temperatura en el Ártico pueden provocar fatiga de expansión y contracción. La estructura circundante de la Unidad condensadora rusa FAW permite ligeras, movimiento controlado del núcleo, Minimizar la tensión en las uniones soldadas que conectan los tubos y las aletas.. Cualquier falla en el Ensamblaje del condensador Las juntas soldadas provocarían una fuga inmediata de refrigerante., apagar el sistema de CA por completo, que es un importante problema de seguridad en climas extremos.

El Unidad condensadora rusa FAW También presenta elementos de diseño internos que abordan la necesidad de subenfriamiento.. Después de que el refrigerante se condensa en líquido, debe enfriarse más para maximizar la eficiencia del sistema. El diseño de microcanales del Ensamblaje del condensador Garantiza que el refrigerante pase suficiente tiempo en la unidad para lograr un subenfriamiento óptimo., proporcionando aire más frío en el núcleo del evaporador. Esta operación de alta eficiencia permite Unidad condensadora rusa FAW para realizar su función de deshumidificación de manera efectiva, lo cual es vital para mantener una clara, parabrisas libre de escarcha en condiciones invernales.

Arquitectura de fijación: Pernos combinados

La integridad estructural del Unidad condensadora rusa FAW El montaje depende de sujetadores especializados.: el Perno combinado (Número de pieza. CQ1460820) y el un poco más largo Perno combinado (Número de pieza. CQ1460825). El término “Perno combinado” significa que estos sujetadores de alta resistencia incluyen arandelas cautivas preensambladas, normalmente una arandela plana y una arandela de seguridad con resorte. Esta es una característica crítica de control de calidad para el Unidad condensadora rusa FAW instalación. Elimina el riesgo de que los mecánicos omitan la arandela antivibraciones., lo que conduciría inevitablemente a un aflojamiento.

Las dos longitudes diferentes del Perno combinado (CQ1460820 y CQ1460825) están especificados para adaptarse a los diferentes espesores de los soportes estructurales y puntos de montaje en el chasis.. La precisión en la longitud es esencial; El uso de una longitud incorrecta puede hacer que el perno toque fondo antes de alcanzar el par requerido o provocar un enganche insuficiente de la rosca., comprometer la capacidad de carga. La cuidadosa selección de estos sujetadores asegura que todo el Unidad condensadora rusa FAW permanece rígidamente fijo a pesar de la vibración extrema del motor y la transmisión del camión volquete.

El tratamiento superficial del Perno combinado También está diseñado para el corrosivo ambiente ártico.. Cuentan con un recubrimiento de alto rendimiento, a menudo con escamas de zinc o Dacromet, que es muy superior al recubrimiento de zinc estándar.. Este recubrimiento garantiza que las roscas no se atasquen debido a la oxidación causada por la exposición a la sal de la carretera., permitiendo el Unidad condensadora rusa FAW Se puede quitar fácilmente para reparar o reemplazar el radiador., mantener la capacidad de servicio del vehículo y reducir el tiempo de inactividad de la flota.

The spring washer element within the Perno combinado is essential for dynamic load security. The constant jarring and shaking inherent in mining operations can slowly back out a standard bolt. The spring action provides continuous, reactive tension, maintaining the critical preload force that keeps the Ensamblaje del condensador brackets locked against the frame. Esto asegura que el Unidad condensadora rusa FAW mounting maintains its integrity, preventing rattling and potential fatigue damage to the core’s refrigerant lines.

Load Distribution and Locking Mechanisms

Complementing the bolt assembly is the Tuerca hexagonal (Número de pieza. CQ34008). Four of these nuts are used to anchor the Unidad condensadora rusa FAW mounting brackets to the chassis, typically in through-hole applications where the vehicle structure cannot be threaded. These nuts are specified to match the high tensile strength of the Perno combinado (Número de pieza. CQ1460820 y CQ1460825), Asegurarse de que el punto débil no sea el sistema de fijación sino la zona arquitectónica prevista.. Esta fuerza es vital para absorber la energía de impactos frontales menores comunes en las operaciones de tajo..

El alto par aplicado a la Tuerca hexagonal crea la fuerza de compresión necesaria para sostener el Ensamblaje del condensador estructura de montaje firmemente contra el marco. Esta rigidez evita que toda la unidad vibre excesivamente, que de otro modo podría dañar las delicadas aletas de aluminio del Ensamblaje del condensador. La estabilidad proporcionada por el montaje seguro del Unidad condensadora rusa FAW Es esencial para maximizar la eficiencia del diseño de flujo paralelo., ya que el movimiento incontrolado interrumpiría el flujo de aire a través del intercambiador de calor.

Los protocolos de mantenimiento enfatizan la importancia de utilizar sólo materiales genuinos. Tuerca hexagonal y Perno combinado componentes. Sustituirlos por hardware de baja calidad compromete la capacidad del sistema para resistir el estrés térmico y vibratorio del entorno ártico.. La integridad de la fijación garantiza que el Unidad condensadora rusa FAW mantiene su alineación precisa con el radiador y la cubierta del ventilador de refrigeración, que es necesario para un rechazo eficiente del calor. Desalineación, causado por sujetadores flojos, Reduce significativamente el rendimiento del sistema de control climático..

Además, el revestimiento anticorrosión en el Tuerca hexagonal Previene el irritamiento: la soldadura de las roscas de los pernos a las roscas de las tuercas bajo alta presión y vibración.. El irritamiento haría imposible el futuro desmontaje para mantenimiento. El recubrimiento especializado en el Unidad condensadora rusa FAW El hardware garantiza que la conexión se mantenga fuerte pero liberable., Proporcionar a los mecánicos de flotas la facilidad de servicio que necesitan para operar el camión volquete CA3250 de manera eficiente en las duras condiciones rusas., proteger la confiabilidad del Unidad condensadora rusa FAW.

Dinámica de refrigerantes y protección del medio ambiente

El propósito principal de la Ensamblaje del condensador dentro del Unidad condensadora rusa FAW es la conversión de fase. El gas refrigerante a alta presión ingresa a la unidad y rechaza su calor a la atmósfera., volviendo a un estado líquido. Esta eficiencia se mide en el subenfriamiento logrado dentro del Ensamblaje del condensador. El diseño presenta múltiples pasadas dentro del núcleo., maximizar el tiempo que el refrigerante pasa en contacto con las aletas enfriadas. Cuanto mayor sea el subenfriamiento, mayor será la eficiencia de todo el ciclo de refrigeración, lo que lleva a un enfriamiento más rápido de la cabina.

El robusto montaje del Unidad condensadora rusa FAW También es vital para proteger las líneas de refrigerante.. La tubería de alta presión que conecta el compresor al Ensamblaje del condensador está sujeto a pulsaciones y vibraciones extremas. Fijación segura con el Perno combinado (CQ1460820 y CQ1460825) y el Tuerca hexagonal evita el movimiento excesivo de la unidad, lo que podría fatigar las líneas de refrigerante y causar fugas catastróficas. Un simple fallo en el sistema de montaje puede provocar una pérdida total de refrigerante., hacer que el sistema de aire acondicionado quede inoperable inmediatamente.

El posicionamiento hacia adelante del Unidad condensadora rusa FAW lo hace altamente vulnerable al daño por impacto. Las aletas de aluminio son delgadas y se dañan fácilmente con piedras y escombros.. Los soportes estructurales y los pernos de montaje., asegurado por el Tuerca hexagonal, proporcionar una defensa perimetral rígida. Usando lo especificado Ensamblaje del condensador Garantiza que el propio núcleo tenga suficiente resistencia para resistir daños menores sin fugas inmediatas.. Esta función de blindaje frontal es una consideración clave para los camiones volquete que operan en entornos a cielo abierto donde los escombros voladores son una amenaza constante..

Las comprobaciones de mantenimiento deben centrarse específicamente en el par aplicado al Perno combinado y el estado de los soportes de montaje. Cualquier evidencia de holgura sugiere que se ha permitido que la vibración actúe sobre el marco., arriesgar la integridad de la Ensamblaje del condensador. El Unidad condensadora rusa FAW es un componente de alto costo; por lo tanto, Mantenimiento preventivo de los sujetadores de bajo costo. (el Perno combinado y el Tuerca hexagonal) Proporciona un enorme retorno de la inversión al evitar el reemplazo del núcleo..

Conclusión: Protección del clima y la vida útil de la cabina

El Unidad condensadora rusa FAW El montaje es un sistema vital que va más allá del simple confort., impactando directamente la seguridad del conductor y la vida útil de los activos. Al integrar la alta eficiencia Ensamblaje del condensador con un sistema de fijación meticulosamente diseñado, basado en múltiples Perno combinado variantes y la sólida seguridad del Tuerca hexagonal—FAW garantiza el máximo rechazo térmico e integridad estructural. Este módulo está construido para soportar el frío extremo., vibración fuerte, y elementos corrosivos del medio ambiente ruso..

Para gestores de flotas del camión volquete CA3250, Es obligatorio adherirse a la lista de materiales especificada.. Sustituyendo cualquier componente, particularmente los sujetadores o el Ensamblaje del condensador, corre el riesgo de falla catastrófica del sistema de aire acondicionado. Utilizando piezas originales FAW, especialmente los resistentes a la corrosión Perno combinado y Tuerca hexagonal, Los equipos de mantenimiento garantizan la fiabilidad continua del Unidad condensadora rusa FAW, Garantizar que el camión siga siendo una pieza de maquinaria segura y productiva en los climas más implacables del mundo..

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.