Conduit d'air russe FAW: Ingénierie de précision 5 Conduits stratégiques pour des performances de dégivrage inébranlables

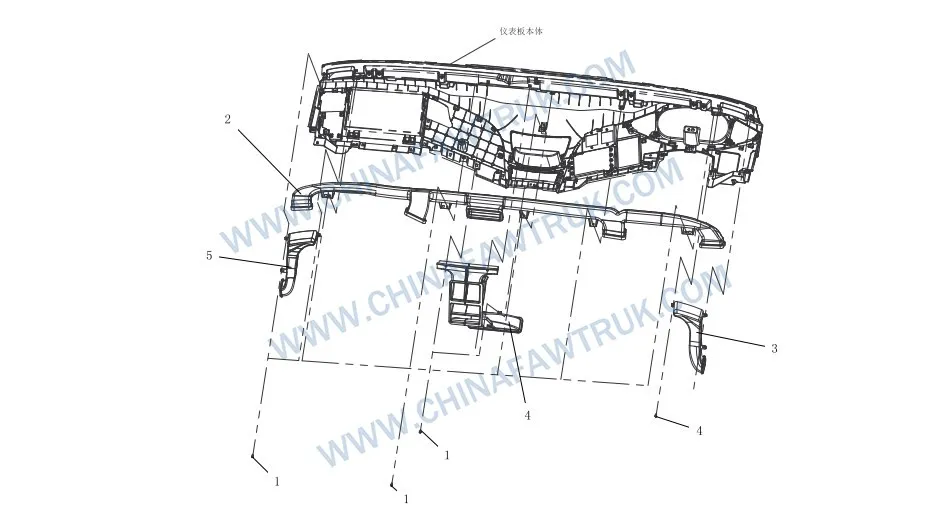

Le Conduit d'air russe FAW system is the circulatory network for conditioned air within the Camion-benne FAW CA3250P66K24L1TE5Z. Dans l'Arctique, the efficiency of heating and defrosting relies entirely on the low-loss transport of high-velocity air from the HVAC core to the cabin outlets. This assembly includes specialized conduits designed to resist thermal energy loss and maximize airflow. By ensuring that warm air reaches the windshield and side windows instantly, le Conduit d'air russe FAW guarantees clear visibility and maintains a safe, habitable environment for the operator, even during sudden temperature drops.

Conduit d'air russe FAW

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

CQ2214216F6 |

Cross Recessed Pan Head Tapping Screw and Flat Washer Combination |

15 |

| 2 |

8102010-B27-C00 |

Face Air Duct Assembly |

1 |

| 3 |

8102065-B27-C00 |

Left Side Door Defrost Air Duct Assembly |

1 |

| 4 |

8102050-B27-C00 |

Central Defrost Air Duct Assembly |

1 |

| 5 |

8102070-B27-C00 |

Right Side Door Defrost Air Duct Assembly |

1 |

Thermal Efficiency and Defrost Logic

The primary safety function of the Conduit d'air russe FAW system is rapid and complete defrosting. The three key components for this task are the Central Defrost Air Duct Assembly (Partie no. 8102050-B27-C00), le Left Side Door Defrost Air Duct Assembly (Partie no. 8102065-B27-C00), et le Right Side Door Defrost Air Duct Assembly (Partie no. 8102070-B27-C00). These conduits must deliver air with minimal temperature drop from the HVAC core to the glass surface. The internal volume of the Central Defrost Air Duct Assembly is precisely calculated to maintain high velocity and pressure.

The materials used for the Conduit d'air russe FAW components are high-density, closed-cell polymers, chosen for their superior thermal insulation properties. Dans le froid, the duct walls themselves act as a heat sink. Inferior ducting materials would absorb and radiate heat energy before it reaches the windshield, rendering the defrost cycle ineffective. The specialized polymer of the Left Side Door Defrost Air Duct Assembly minimizes thermal loss, ensuring that the warm air hitting the glass is hot enough to sublimate ice rapidly.

Le Right Side Door Defrost Air Duct Assembly is specifically contoured to follow the complex geometry of the passenger door structure and dashboard. Its path is designed to avoid sharp bends that would restrict airflow. Airflow restriction reduces velocity, and reduced velocity leads to slower de-icing. The seamless design of the Conduit d'air russe FAW system ensures a continuous, high-volume flow, essential for maintaining maximum visibility during the critical warm-up period of the CA3250 dump truck.

Targeted Comfort: Face and Foot Air Delivery

Beyond defrosting, le Conduit d'air russe FAW system manages driver comfort through the Face Air Duct Assembly (Partie no. 8102010-B27-C00). This central duct provides a high volume of conditioned air directly to the operator’s upper body. During long shifts, maintaining a comfortable temperature and airflow around the face helps to reduce drowsiness and maintain alertness. The multiple outlets within the Face Air Duct Assembly are designed to distribute air evenly, avoiding localized drafts that can cause driver discomfort.

The strategic routing of the Face Air Duct Assembly and the defrost ducts is engineered to prevent interference. When the driver selects the defrost mode, the system prioritizes the flow through the Central Defrost Air Duct Assembly and the side ducts. The internal flap mechanisms within the main HVAC box (which feed the Conduit d'air russe FAW réseau) are precisely calibrated to divert air volume instantly, ensuring the safety function (defrosting) always overrides comfort settings when selected by the driver.

La rigidité structurelle du Conduit d'air russe FAW components is essential for acoustic performance. Air ducts can act as resonators, amplifying the noise from the blower motor. L'épaisseur, molded polymer construction of the Face Air Duct Assembly dampens this acoustic energy. En outre, the secure mounting of all the ducts prevents rattling, which would otherwise plague the cabin. A silent air delivery system is as important as a warm one for maintaining a non-fatiguing environment in the severe Russian operating zone.

Fastening Technology and Airtight Sealing

L'ensemble Conduit d'air russe FAW network is secured by the Cross Recessed Pan Head Tapping Screw and Flat Washer Combination (Partie no. CQ2214216F6). The use of fifteen of these fasteners highlights the comprehensive nature of the duct mounting. The tapping screw design creates a robust, self-locking thread interface with the dashboard structure. This is necessary to counteract the constant chassis vibration inherent in a heavy-duty dump truck, s'assurer que le Central Defrost Air Duct Assembly remains tightly fastened to the dashboard plenum.

Le “Combinaison” fonctionnalité, including a captive flat washer, is crucial for securing the polymer ducts. The flat washer spreads the clamping load of the tapping screw over a larger area of the plastic flange. This prevents the screw head from cracking the mounting boss of the Left Side Door Defrost Air Duct Assembly when torque is applied. Preventing stress fractures is vital for maintaining the airtight seal of the Conduit d'air russe FAW system over time.

To ensure zero thermal loss and airtight performance, foam gaskets are utilized at the connection points between the ducts and the main HVAC unit. These gaskets work in conjunction with the force provided by the Cross Recessed Pan Head Tapping Screw and Flat Washer Combination. The tight seal prevents unfiltered, unconditioned air from leaking into the cabin, which would compromise the health and comfort delivered by the Conduit d'air russe FAW système.

Maintenance and Component Longevity

Alors que le Conduit d'air russe FAW components are designed for a long service life, proper installation and maintenance are key. Mechanics must ensure that when reinstalling the dashboard, the connections for the Right Side Door Defrost Air Duct Assembly are fully seated against the HVAC box. An incomplete connection leads to significant air loss, reducing defrost performance. The polymer material is resistant to most common cleaning agents, but inspection should focus on thermal degradation.

The robust nature of the duct assemblies, including the **Face Air Duct Assembly**, means that failure is usually linked to impact damage or incorrect reassembly. The rigidity of the **Central Defrost Air Duct Assembly** is built-in; it must not be replaced with flexible hosing, which would cause significant pressure loss and render the system useless in cold weather. Only the authentic, specified rigid polymer ducts will provide the required air pressure to battle the frost on the windshield in the CA3250 dump truck.

La longévité de l'ensemble Conduit d'air russe FAW system is directly related to the integrity of the Cross Recessed Pan Head Tapping Screw and Flat Washer Combination. Over-torquing can lead to component failure, while under-torquing leads to vibration and air leaks. By using the correct tooling and genuine components, fleet managers guarantee that their Conduit d'air russe FAW network remains a highly efficient, airtight system, essential for safety and comfort in the extreme environment of the Russian mining frontier.

Conclusion: Seamless Airflow for Safety

Le Conduit d'air russe FAW system is a fundamental part of the CA3250’s Arctic preparedness. From the high-pressure delivery of the **Central Defrost Air Duct Assembly** to the precise mounting of the **Left Side Door Defrost Air Duct Assembly**, every component is designed to minimize loss and maximize thermal transfer. This ensures that the driver always has a clear, frost-free windshield, a non-negotiable safety feature in the mining environment.

For fleet operations, the integrity of the **FAW Russian Air Duct** network is a measure of operational readiness. By utilizing genuine **Face Air Duct Assembly** and side duct components, secured with the correct **Cross Recessed Pan Head Tapping Screw and Flat Washer Combination**, maintenance teams maintain the high performance standards demanded by FAW. This commitment ensures that the truck remains a highly efficient, fiable, and safe environment for its operator, ensuring continuous productivity in the world’s coldest regions.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.