Supports et tuyauterie russes FAW: 30 Composants stratégiques pour les structures & Intégrité des fluides dans l'Arctique

Le Supports et tuyauterie russes FAW assembly forms the skeletal and circulatory framework for the CA3250P66K24L1TE5Z dump truck’s emission control system. Operating in the unforgiving Russian climate requires more than just functional components; it demands a mounting architecture capable of resisting chassis torsion on frozen mine roads and a piping network that actively combats fluid crystallization at -40°C. This guide analyzes the heated transport lines, the heavy-duty vibration isolation brackets, and the specialized fastening logic that holds the SCR system together.

Supports et tuyauterie russes FAW

Heated Transport: Fighting the Freeze

The defining feature of the Supports et tuyauterie russes FAW assembly is its sophisticated fluid transport network. In standard climates, simple rubber hoses suffice. Cependant, in the Russian Federation, the urea solution (AdBlue) used for emissions control freezes solid at -11°C. To maintain compliance and engine performance, FAW employs a network of electrically heated lines. Le Tuyau d'alimentation en urée chauffé électriquement – Du réservoir à la pompe (Partie no. 1160120-66W) et Tuyau d'alimentation en urée chauffé électriquement – Pompe à buse (Partie no. 1160130-66W) feature integrated resistive heating elements. These elements are wrapped around the core tube and insulated with a thermal jacket, ensuring that the fluid remains liquid from the reservoir to the injector tip, even when ambient temperatures plummet.

Complementing the electrical heating is a coolant-based thermal management loop. Le Tuyau d'eau d'entrée de chauffage à l'urée – Moteur à solénoïde (Partie no. 1160128-55R.) et Conduite d'eau de retour de chauffage à l'urée (Partie no. 1160127-28V) circulate hot engine coolant to the urea tank coil. This bulk heating capability is critical for thawing the main reservoir after a long overnight park. The piping materials used in the Supports et tuyauterie russes FAW system are formulated from high-grade EPDM and reinforced polymers to withstand the dual stresses of internal chemical corrosion from urea and external thermal shock from the Arctic environment.

The system also includes specialized cooling lines for the injector itself, Plus précisément le Ensemble de tuyau d'eau d'entrée de refroidissement de buse d'urée (Partie no. 1160315-61S). While heating is needed for the fluid, the nozzle tip sits in the exhaust stream and requires active cooling to prevent the solenoid from overheating. This duality—heating the lines while cooling the nozzle—demonstrates the complex thermal balancing act performed by the Supports et tuyauterie russes FAW système. Each pipe is precision-bent to route through the chassis without rubbing against sharp edges or hot exhaust components, a critical layout consideration for longevity.

Connections are secured with the Petit collier de serrage à vis sans fin (Partie no. CQ67625). Unlike spring clamps which can lose tension in extreme cold due to metal fatigue, worm drive clamps allow for positive mechanical torque application. Cela garantit que le Supports et tuyauterie russes FAW connections remain leak-free even as the hoses contract slightly in sub-zero temperatures.

Rigidité structurelle: The Bracket Architecture

The plumbing network is supported by a series of heavy-duty brackets designed to isolate the lines from chassis vibration. Le Support de tuyauterie de buse d'urée (Partie no. 1160126-73W) et Support de tuyauterie de pompe à urée (Partie no. 1160126-61S) act as the primary anchor points. Dans le Supports et tuyauterie russes FAW assemblée, these brackets are manufactured from thick-gauge steel, often stamped with stiffening ribs to raise their natural frequency. This prevents the brackets from resonating with the diesel engine’s vibration, which would otherwise lead to fatigue cracks and eventual failure.

The largest structural component is the Ensemble de soudage de support de réservoir d'urée (Partie no. 1160105-66W). This welded assembly must support the full weight of the urea tank (approximately 40-50kg when full) while the truck navigates the rough, frozen terrain of a Siberian mine. The bracket design utilizes a cantilevered geometry that transfers load directly to the frame rails. Le Supports et tuyauterie russes FAW engineering standards dictate high-quality welds and corrosion-resistant coatings (such as powder coating or hot-dip galvanizing) to prevent rust jacking in the salt-laden winter road environment.

To secure the tank to the bracket, le système utilise le Ensemble de sangle de réservoir d'urée (Partie no. 1160140-66W). These stainless steel straps provide high tensile strength. Cependant, metal-on-plastic contact is avoided by using the Doublure de sangle (Partie no. 1160134-87V). This rubber interface is a critical part of the Supports et tuyauterie russes FAW système. It provides friction to hold the tank in place and acts as a damper to absorb high-frequency vibrations that could otherwise abrade the polymer tank wall, conduisant à des fuites.

Additional support is provided by the Support de tuyauterie d'urée (Partie no. 1160126A76R) and the secondary Support de tuyauterie de buse d'urée (Partie no. 1160126-93B). These smaller brackets manage the routing of the flexible lines, ensuring they maintain proper bend radii and do not droop onto the driveshaft or exhaust. The meticulous placement of these supports highlights the attention to detail in the Supports et tuyauterie russes FAW mise en page.

Secure Fixation: Boulons, Noix, and Cable Ties

L'intégrité du Supports et tuyauterie russes FAW assembly relies on a specific suite of fasteners. Le Boulon à bride hexagonale (Standard) (Partie no. Q1841445T) et le Boulon convexe à tête hexagonale (Partie no. Q1841455T) are the primary structural fasteners. The flange head design is essential for distributing clamping load over the bracket surfaces, preventing the bolt head from embedding into the metal and losing torque.

For mounting smaller components, le Boulon combiné (Numéros de pièces. CQ1460816 et CQ1461025) est utilisé. These bolts feature integrated captive washers, which speed up assembly and ensure that a washer is never forgotten during maintenance. In the high-vibration environment of the Supports et tuyauterie russes FAW système, maintaining bolt preload is vital. A loose bracket can cause a domino effect of failures, leading to ruptured lines and emissions system shutdown.

La gestion des câbles est assurée par le Attache de câble en plastique (Partie no. T67417246). Il y a 24 of these units specified in the breakdown. These are not standard nylon ties; they are formulated with impact modifiers to remain flexible at -40°C. Standard ties would shatter in the Russian cold, leaving wiring and hoses unsupported. Le Supports et tuyauterie russes FAW system relies on these ties to bundle hoses together, increasing their collective stiffness and resistance to harmonic vibration.

Enfin, the connection of the nozzle assembly uses the Vis à capuchon de tête hexagonale (Partie no. CQ2180625). This high-strength fastener allows for precise torque application in the confined space near the exhaust pipe. The use of high-grade steel for these screws ensures they do not stretch or yield under the thermal expansion cycles of the exhaust system, maintaining a gas-tight seal for the Supports et tuyauterie russes FAW interface.

Liste de répartition des composants

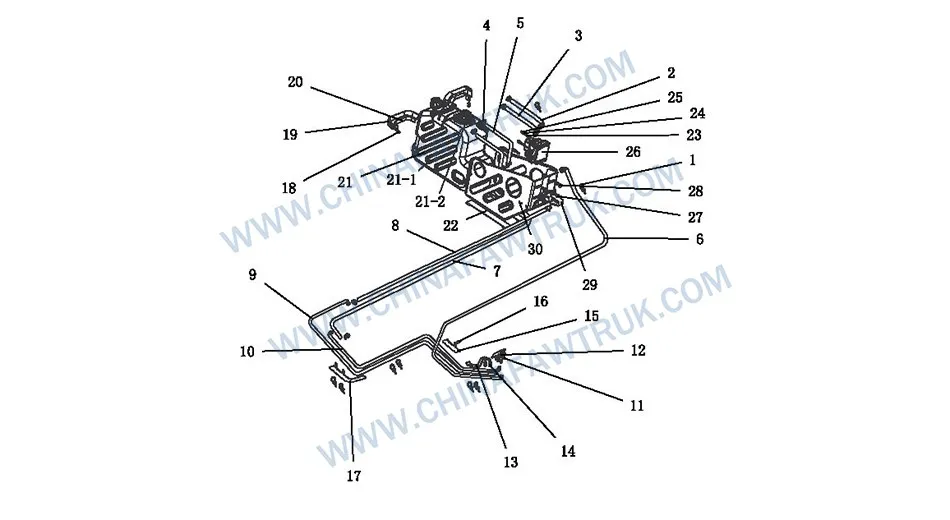

Le tableau suivant fournit l'intégralité, unedited breakdown of the Supports et tuyauterie russes FAW assemblée. Il comprend tout 30 component types listed in the assembly diagrams, en veillant à ce que chaque support, tuyau, and fastener is accounted for.

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

T67417246 |

Attache de câble en plastique |

24 |

| 2 |

1160120-66W |

Tuyau d'alimentation en urée chauffé électriquement – Du réservoir à la pompe |

1 |

| 3 |

1160250-66W |

Tuyau d'alimentation en urée chauffé électriquement – De la pompe au réservoir |

1 |

| 4 |

CQ67625 |

Petit collier de serrage à vis sans fin |

6 |

| 5 |

1160129-66W |

Tuyau d'eau d'entrée de chauffage à l'urée – Solénoïde au réservoir |

1 |

| 6 |

1160130-66W |

Tuyau d'alimentation en urée chauffé électriquement – Pompe à buse |

1 |

| 7 |

1160127-28V |

Conduite d'eau de retour de chauffage à l'urée |

1 |

| 8 |

1160128-55R. |

Tuyau d'eau d'entrée de chauffage à l'urée – Moteur à solénoïde |

1 |

| 9 |

1160315-61S |

Ensemble de tuyau d'eau d'entrée de refroidissement de buse d'urée |

1 |

| 10 |

1160310-61S |

Ensemble de tuyau d'eau de retour de refroidissement de buse d'urée |

1 |

| 11 |

CQ2180625 |

Vis à capuchon de tête hexagonale |

3 |

| 12 |

1161210-76W |

Ensemble de buse d'urée |

1 |

| 13 |

1160126-73W |

Support de tuyauterie de buse d'urée |

1 |

| 14 |

CQ1460816 |

Boulon combiné |

2 |

| 15 |

1160126-61S |

Support de tuyauterie de pompe à urée |

1 |

| 16 |

CQ1461025 |

Boulon combiné |

1 |

| 17 |

1160126A76R |

Support de tuyauterie d'urée |

1 |

| 18 |

CQ34008 |

Écrou hexagonal |

8 |

| 19 |

1160140-66W |

Ensemble de sangle de réservoir d'urée |

2 |

| 20 |

1160134-87V |

Doublure de sangle |

2 |

| 21 |

1160010-76W |

Assemblage du réservoir d'urée |

1 |

| 22 |

1160117-66W |

Revêtement inférieur du réservoir d'urée |

2 |

| 23 |

CQ1500860 |

Boulon à tête hexagonale |

3 |

| 24 |

Q40308 |

Rondelle à ressort |

3 |

| 25 |

Q40108 |

Machine à laver |

3 |

| 26 |

1161010-76W |

Ensemble de pompe à urée |

1 |

| 27 |

Q1841445T |

Boulon de bride hexadécimal (Standard) |

2 |

| 28 |

Q1841455T |

Boulon convexe à tête hexagonale |

2 |

| 29 |

1160126-93B |

Support de tuyauterie de buse d'urée |

1 |

| 30 |

1160105-66W |

Ensemble de soudage de support de réservoir d'urée |

1 |

Diagnostic Protocols for Structural Integrity

Inspecter le Supports et tuyauterie russes FAW assembly is a vital part of preventative maintenance. The first step is to check for leaks at the Petit collier de serrage à vis sans fin locations. Cold flow of the rubber hoses can cause them to shrink, loosening the clamp tension. A white, crystalline buildup of dried urea indicates a leak that must be addressed immediately by tightening the clamp or replacing the hose.

Structural inspection should focus on the Ensemble de soudage de support de réservoir d'urée et le Support de tuyauterie de pompe à urée. Look for stress cracks near the weld zones or bolt holes. Vibration fatigue is a common enemy in heavy-duty trucks. If a bracket is cracked, it allows the component it supports to vibrate excessively, which will eventually fatigue the rigid fluid lines connected to it.

Enfin, examine the condition of the Ensemble de sangle de réservoir d'urée. Assurez-vous que le Doublure de sangle is in place and not worn through. Metal-on-plastic contact will quickly abrade the urea tank wall, leading to a puncture. Vérifiez le Plastic Cable Ties to ensure they haven’t snapped in the cold, leaving wiring harnesses to dangle and chafe against the chassis.

Conclusion: The Backbone of Emissions Control

Le Supports et tuyauterie russes FAW assembly is the unsung hero of the truck’s environmental compliance system. By providing rigid support and heated transport for the urea solution, it ensures that the SCR system functions correctly in all weather conditions. The engineering behind the heated lines and vibration-isolating brackets reflects a deep understanding of the challenges posed by the Russian operating environment.

Pour les propriétaires de flotte, maintaining this assembly with genuine FAW parts is critical. Generic hoses may lack the integrated heating elements or chemical resistance required for long-term durability. En investissant dans l'authentique Supports et tuyauterie russes FAW composants, you protect your vehicle from emissions-related downtime and ensure it remains a reliable asset in your logistics fleet.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.