Bienvenue dans cette analyse technique complète du Assemblage à deux axes FAW, also known as the transmission main shaft or “deuxième arbre,” Pour le FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This component is the primary output shaft of the transmission’s main box.

Le Assemblage à deux axes FAW is responsible for holding all the “conduit” engrenages (1St, 2nd, 3rd, 4ème, 5ème, and reverse) and the synchronizer “manchons coulissants” that lock them in place. It receives torque from the counter-shaft and transmits the selected gear ratio to the truck’s driveline.

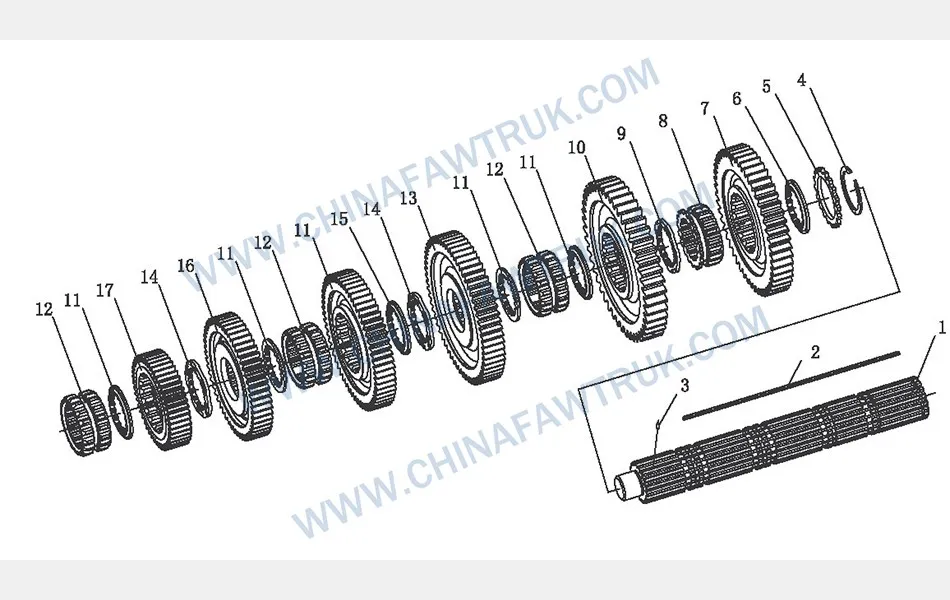

This guide is an essential resource for professional transmission rebuilders and parts specialists. Nous déconstruirons l'ensemble Assemblage à deux axes FAW dans son 17 composants réparables, y compris l'arbre principal (1701301-A9K), all individual helical gears, the sliding sleeves, and the critical bearings and circlips that maintain perfect alignment.

L'épine dorsale du Assemblage à deux axes FAW is the ‘Second shaft’ (1701301-A9K), also known as the main shaft. C'est un seul, massif, composant forgé en matériau à haute résistance, acier cémenté. It is designed to withstand the full, multiplied torque of the engine’s output.

The function of this shaft is to act as the “sortir” shaft of the main gearbox. Unlike the counter-shaft (which is always spinning at a fixed ratio to the engine), le Assemblage à deux axes FAW‘s speed *changes* based on the gear selected.

This shaft is a complex piece of precision machining. It features a long, splined section where the synchronizer hubs (manchons coulissants) are fixed. It also has multiple, mirror-smooth journals where the “freewheeling” driven gears ride on needle bearings. L'avant “nez” of this shaft fits into the “douille pilote” (1701111-A7G) inside the input shaft, ensuring perfect alignment. A bent or twisted main shaft will cause catastrophic gear failure, making the integrity of the Assemblage à deux axes FAW primordial.

Le noyau “logique” de la Assemblage à deux axes FAW est-ce que c'est “constant-mesh” conception. This parts list details all the “conduit” engrenages, which are in permanent, maillage constant avec le “conduire” gears on the counter-shaft. These gears are:

When the truck is in neutral, the clutch is engaged, and the input shaft is spinning the counter-shaft. This means all of these driven gears are *also* spinning, but because they ride on bearings on the ‘Second shaft’, ils sont “freewheeling.” They are not locked to the Assemblage à deux axes FAW, so no power is transmitted.

When the driver selects a gear (Par exemple, 3rd), the shift fork moves a ‘Sliding sleeve’ (1701316-A7G), which locks the ‘Third gear-second shaft’ (1701366-A9K) au Assemblage à deux axes FAW. At that moment, power flows from the counter-shaft, through the 3rd gear pair, and onto the Assemblage à deux axes FAW (main shaft), which then spins at the 3rd gear ratio. All other gears on the shaft continue to freewheel.

Le “logique” of gear selection in the Assemblage à deux axes FAW is performed by the ‘Sliding sleeve’ (1701316-A9K) and ‘Sliding sleeve’ (1701316-A7G) unités. The list calls for a total of four (one -A9K, three -A7G). These are the synchronizer hubs.

Each sliding sleeve is what the driver’s shift fork physically moves. The *inside* of the sleeve is splined and is permanently locked to the Assemblage à deux axes FAW (main shaft). The *outside* of the sleeve is a groove for the shift fork. When the driver moves the shifter, this sleeve slides “avant” ou “en arrière” on the shaft.

The sides of the sleeve, and the sides of the freewheeling gears, have a set of “dents de chien” (ou “clutching teeth”). When the sleeve slides over, its internal teeth engage with the dog teeth on the side of the gear. This creates a solid, positive lock, forcing the freewheeling gear to spin at the same speed as the Assemblage à deux axes FAW.

To prevent a “affûtage” changement, this sleeve assembly also contains a “synchroniseur” (ou “anneau bloqueur”). This is a tapered bronze ring that acts as a small, cone-shaped clutch. As the sleeve moves forward, it first pushes this bronze ring onto a matching cone on the gear. The friction between the two instantly equalizes the speed of the sleeve (spinning at shaft speed) and the gear (freewheeling at a different speed). Once their speeds are matched, the sleeve can slide over the dog teeth smoothly and silently. Ce “sync-then-lock” logic is the genius of the Assemblage à deux axes FAW.

A constant-mesh gearbox requires perfect alignment. The gears on the Assemblage à deux axes FAW must be perfectly aligned with their counterparts on the counter-shaft. This alignment, ou “fin de jeu,” is controlled by a system of precision washers and circlips.

The parts list calls for five ‘Limit washer – engrenage’ (1701327-A7G) and three ‘Inter-shaft limit washer’ (1701318-A9K/A7G). These are not standard washers. Ils sont “cales”—hardened, precision-ground washers of a very specific thickness. They are placed between the freewheeling gears and their synchronizer hubs to control the “fin de jeu” (the fore-and-aft slop).

De la même manière, the ‘Locating retaining ring-reverse gear’ (1701312-A7G) and ‘Limit washer-reverse gear’ (1701313-A7G) are a matched set. They work together to lock the ‘Reverse gear-second shaft’ (1701311-A7G) in its exact position on the Assemblage à deux axes FAW, ensuring it aligns perfectly with its idler gear.

The ‘Three-sided key’ (1701396-A9K) and its ‘Circlip’ (1701333-A7G) are used to permanently lock a main synchronizer hub to the Assemblage à deux axes FAW, while the ‘Spring dowel pin’ (Q5280310) is likely used to lock a shaft or pin in place. This entire system of small parts is what guarantees the quiet, longue durée, and precise operation of the Assemblage à deux axes FAW.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 17 components identified in the ‘Dual-Axis (Second Shaft) Assemblée’ schéma du tracteur FAW CA4251P66K24T1A3E5. Une reconstruction du Assemblage à deux axes FAW requires meticulous attention to the placement of each washer and circlip.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1701301-A9K | Deuxième arbre | 1 |

| 2 | 1701396-A9K | Three-sided key | 1 |

| 3 | Q5280310 | Goupille à ressort | 1 |

| 4 | 1701333-A7G | Circlip-three-sided key | 1 |

| 5 | 1701312-A7G | Locating retaining ring – marche arrière | 1 |

| 6 | 1701313-A7G | Limit washer – marche arrière | 1 |

| 7 | 1701311-A7G | Reverse gear – deuxième arbre | 1 |

| 8 | 1701316-A9K | Sliding sleeve – inverse | 1 |

| 9 | 1701318-A9K | Inter-shaft limit washer | 1 |

| 10 | 1701326-A9K | First gear – deuxième arbre | 1 |

| 11 | 1701327-A7G | Limit washer – engrenage | 5 |

| 12 | 1701316-A7G | Sliding sleeve | 3 |

| 13 | 1701356-A9K | Second gear – deuxième arbre | 1 |

| 14 | 1701318-A7G | Inter-shaft limit washer | 2 |

| 15 | 1701366-A9K | Troisième vitesse – deuxième arbre | 1 |

| 16 | 1701386-A9K | Quatrième vitesse – deuxième arbre | 1 |

| 17 | 1701323-A1K | Cinquième vitesse – deuxième arbre | 1 |

Les spécifications pour le Assemblage à deux axes FAW are defined by its function as the transmission’s main output shaft, which holds all the freewheeling “conduit” gears and the synchronizer hubs. The proper shimming of the Assemblage à deux axes FAW est critique.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Assemblage à deux axes FAW (Arbre principal) |

| Nom commun | Second Shaft / Main Shaft Assembly |

| Réf. arbre principal | 1701301-A9K |

| Type de système | Maillage constant, Synchronized |

| Driven Gears | 1St, 2nd, 3rd, 4ème, 5ème, and Reverse |

| Gear Actuators | 4x Sliding Sleeves (Synchronizer Hubs) |

| Alignment Control | Limit Washers (Cales) and Retaining Rings |

| Shaft Locking | Keys (Woodruff, Plat) and Pins |

| Fonction principale | To carry all freewheeling “conduit” gears and be locked to the selected gear via a sliding sleeve, transmitting power to the output. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.