مرحبا بكم في هذا التحليل الفني الكامل لل FAW Dual-Axis Assembly, also known as the transmission main shaft or “العمود الثاني,” لفاو جيفانغ CA4251P66K24T1A3E5 6×4 جرار نصف مقطورة ديزل. This component is the primary output shaft of the transmission’s main box.

ال FAW Dual-Axis Assembly is responsible for holding all the “مدفوعة” التروس (1شارع, 2اختصار الثاني, 3ثالثا, 4ذ, 5ذ, and reverse) and the synchronizer “الأكمام المنزلقة” that lock them in place. It receives torque from the counter-shaft and transmits the selected gear ratio to the truck’s driveline.

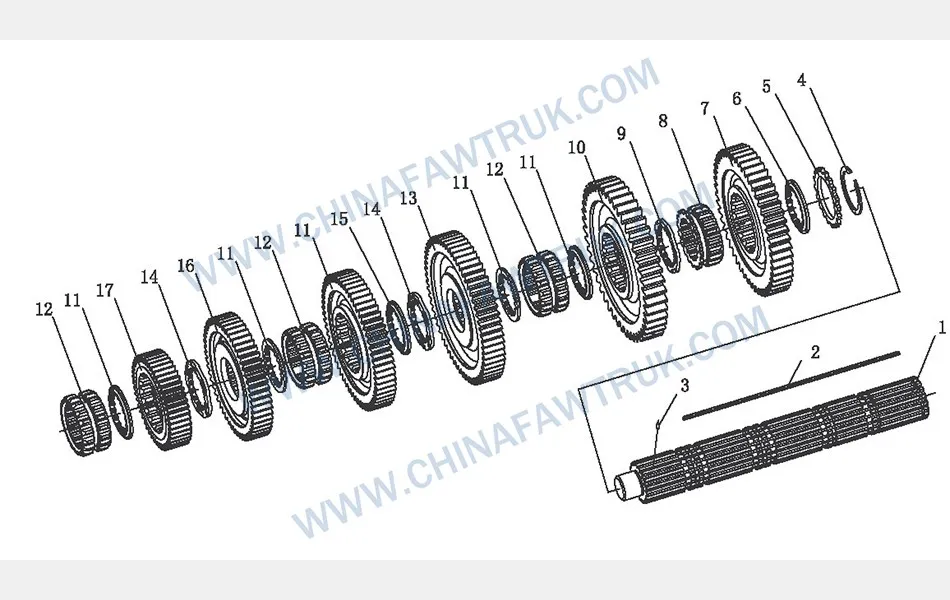

This guide is an essential resource for professional transmission rebuilders and parts specialists. سنقوم بتفكيك الكل FAW Dual-Axis Assembly فيه 17 مكونات صالحة للخدمة, بما في ذلك رمح الرئيسي (1701301-A9K), all individual helical gears, the sliding sleeves, and the critical bearings and circlips that maintain perfect alignment.

العمود الفقري لل FAW Dual-Axis Assembly is the ‘Second shaft’ (1701301-A9K), also known as the main shaft. هذه واحدة, جَسِيم, مكون مزورة مصنوعة من قوة عالية, حالة تصلب الصلب. It is designed to withstand the full, multiplied torque of the engine’s output.

The function of this shaft is to act as the “الإخراج” shaft of the main gearbox. Unlike the counter-shaft (which is always spinning at a fixed ratio to the engine), ال FAW Dual-Axis Assembly‘s speed *changes* based on the gear selected.

This shaft is a complex piece of precision machining. It features a long, splined section where the synchronizer hubs (الأكمام المنزلقة) are fixed. It also has multiple, mirror-smooth journals where the “freewheeling” driven gears ride on needle bearings. الجبهة “أنف” of this shaft fits into the “جلبة الطيار” (1701111-A7G) inside the input shaft, ensuring perfect alignment. A bent or twisted main shaft will cause catastrophic gear failure, making the integrity of the FAW Dual-Axis Assembly paramount.

جوهر “منطق” التابع FAW Dual-Axis Assembly هو “constant-mesh” تصميم. This parts list details all the “مدفوعة” التروس, which are in permanent, شبكة ثابتة مع “يقود” gears on the counter-shaft. These gears are:

When the truck is in neutral, the clutch is engaged, and the input shaft is spinning the counter-shaft. This means all of these driven gears are *also* spinning, but because they ride on bearings on the ‘Second shaft’, هم كذلك “freewheeling.” They are not locked to the FAW Dual-Axis Assembly, so no power is transmitted.

عندما يختار السائق العتاد (على سبيل المثال, 3ثالثا), the shift fork moves a ‘Sliding sleeve’ (1701316-A7G), which locks the ‘Third gear-second shaft’ (1701366-A9K) إلى FAW Dual-Axis Assembly. في تلك اللحظة, power flows from the counter-shaft, through the 3rd gear pair, and onto the FAW Dual-Axis Assembly (main shaft), which then spins at the 3rd gear ratio. All other gears on the shaft continue to freewheel.

ال “منطق” of gear selection in the FAW Dual-Axis Assembly is performed by the ‘Sliding sleeve’ (1701316-A9K) and ‘Sliding sleeve’ (1701316-A7G) وحدات. The list calls for a total of four (one -A9K, three -A7G). These are the synchronizer hubs.

Each sliding sleeve is what the driver’s shift fork physically moves. The *inside* of the sleeve is splined and is permanently locked to the FAW Dual-Axis Assembly (main shaft). The *outside* of the sleeve is a groove for the shift fork. When the driver moves the shifter, this sleeve slides “إلى الأمام” أو “إلى الوراء” on the shaft.

The sides of the sleeve, and the sides of the freewheeling gears, have a set of “أسنان الكلب” (أو “clutching teeth”). When the sleeve slides over, its internal teeth engage with the dog teeth on the side of the gear. وهذا يخلق مادة صلبة, positive lock, forcing the freewheeling gear to spin at the same speed as the FAW Dual-Axis Assembly.

To prevent a “grinding” يحول, this sleeve assembly also contains a “المزامن” (أو “blocker ring”). This is a tapered bronze ring that acts as a small, cone-shaped clutch. As the sleeve moves forward, it first pushes this bronze ring onto a matching cone on the gear. The friction between the two instantly equalizes the speed of the sleeve (spinning at shaft speed) and the gear (freewheeling at a different speed). Once their speeds are matched, the sleeve can slide over the dog teeth smoothly and silently. هذا “sync-then-lock” logic is the genius of the FAW Dual-Axis Assembly.

A constant-mesh gearbox requires perfect alignment. التروس على FAW Dual-Axis Assembly must be perfectly aligned with their counterparts on the counter-shaft. This alignment, أو “نهاية اللعب,” is controlled by a system of precision washers and circlips.

The parts list calls for five ‘Limit washer – العتاد’ (1701327-A7G) and three ‘Inter-shaft limit washer’ (1701318-A9K/A7G). These are not standard washers. هم “الحشوات”—hardened, precision-ground washers of a very specific thickness. They are placed between the freewheeling gears and their synchronizer hubs to control the “نهاية اللعب” (the fore-and-aft slop).

بصورة مماثلة, the ‘Locating retaining ring-reverse gear’ (1701312-A7G) and ‘Limit washer-reverse gear’ (1701313-A7G) are a matched set. They work together to lock the ‘Reverse gear-second shaft’ (1701311-A7G) in its exact position on the FAW Dual-Axis Assembly, ensuring it aligns perfectly with its idler gear.

The ‘Three-sided key’ (1701396-A9K) and its ‘Circlip’ (1701333-A7G) are used to permanently lock a main synchronizer hub to the FAW Dual-Axis Assembly, while the ‘Spring dowel pin’ (س5280310) is likely used to lock a shaft or pin in place. This entire system of small parts is what guarantees the quiet, long-lasting, and precise operation of the FAW Dual-Axis Assembly.

الجدول التالي يوفر كامل, تفصيل مفصل للجميع 17 components identified in the ‘Dual-Axis (Second Shaft) حَشد’ رسم تخطيطي للجرار FAW CA4251P66K24T1A3E5. إعادة بناء FAW Dual-Axis Assembly requires meticulous attention to the placement of each washer and circlip.

| علامة | الجزء لا. | جزء اسم | كمية |

|---|---|---|---|

| 1 | 1701301-A9K | رمح الثاني | 1 |

| 2 | 1701396-A9K | مفتاح ثلاثي الجوانب | 1 |

| 3 | س5280310 | دبوس وتد الربيع | 1 |

| 4 | 1701333-A7G | Circlip-three-sided key | 1 |

| 5 | 1701312-A7G | Locating retaining ring – العتاد العكسي | 1 |

| 6 | 1701313-A7G | Limit washer – العتاد العكسي | 1 |

| 7 | 1701311-A7G | ترس عكسي – العمود الثاني | 1 |

| 8 | 1701316-A9K | كم انزلاق – يعكس | 1 |

| 9 | 1701318-A9K | Inter-shaft limit washer | 1 |

| 10 | 1701326-A9K | العتاد الأول – العمود الثاني | 1 |

| 11 | 1701327-A7G | Limit washer – العتاد | 5 |

| 12 | 1701316-A7G | كم انزلاق | 3 |

| 13 | 1701356-A9K | والعتاد الثاني – العمود الثاني | 1 |

| 14 | 1701318-A7G | Inter-shaft limit washer | 2 |

| 15 | 1701366-A9K | والعتاد الثالث – العمود الثاني | 1 |

| 16 | 1701386-A9K | والعتاد الرابع – العمود الثاني | 1 |

| 17 | 1701323-A1K | والعتاد الخامس – العمود الثاني | 1 |

المواصفات ل FAW Dual-Axis Assembly are defined by its function as the transmission’s main output shaft, which holds all the freewheeling “مدفوعة” gears and the synchronizer hubs. The proper shimming of the FAW Dual-Axis Assembly أمر بالغ الأهمية.

| تطبيق المركبة | فاو جيفانغ CA4251P66K24T1A3E5 6×4 جرار |

| مجموعة المكونات | FAW Dual-Axis Assembly (رمح الرئيسي) |

| الاسم الشائع | Second Shaft / Main Shaft Assembly |

| العمود الرئيسي P/N | 1701301-A9K |

| نوع النظام | شبكة ثابتة, Synchronized |

| Driven Gears | 1شارع, 2اختصار الثاني, 3ثالثا, 4ذ, 5ذ, وعكس |

| Gear Actuators | 4x Sliding Sleeves (Synchronizer Hubs) |

| Alignment Control | Limit Washers (الحشوات) and Retaining Rings |

| Shaft Locking | مفاتيح (Woodruff, مستوي) and Pins |

| الوظيفة الأساسية | To carry all freewheeling “مدفوعة” gears and be locked to the selected gear via a sliding sleeve, transmitting power to the output. |

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.