Bienvenidos a este completo análisis técnico del Conjunto de doble eje FAW, also known as the transmission main shaft or “segundo eje,” Para FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. This component is the primary output shaft of the transmission’s main box.

El Conjunto de doble eje FAW is responsible for holding all the “conducido” engranajes (1calle, 2Dakota del Norte, 3tercero, 4th, 5th, and reverse) and the synchronizer “mangas deslizantes” that lock them in place. It receives torque from the counter-shaft and transmits the selected gear ratio to the truck’s driveline.

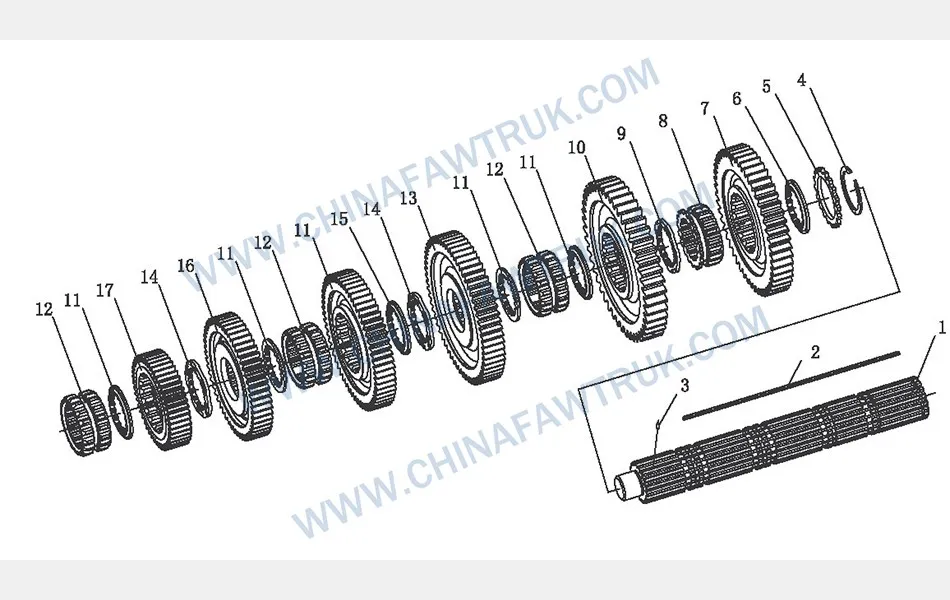

Esta guía es un recurso esencial para reconstructores de transmisiones profesionales y especialistas en repuestos.. Deconstruiremos todo Conjunto de doble eje FAW en su 17 componentes reparables, incluyendo el eje principal (1701301-A9K), all individual helical gears, the sliding sleeves, and the critical bearings and circlips that maintain perfect alignment.

La columna vertebral de la Conjunto de doble eje FAW is the ‘Second shaft’ (1701301-A9K), also known as the main shaft. Este es un solo, masivo, componente forjado hecho de alta resistencia, acero cementado. It is designed to withstand the full, multiplied torque of the engine’s output.

The function of this shaft is to act as the “producción” shaft of the main gearbox. Unlike the counter-shaft (which is always spinning at a fixed ratio to the engine), el Conjunto de doble eje FAW‘s speed *changes* based on the gear selected.

This shaft is a complex piece of precision machining. It features a long, splined section where the synchronizer hubs (mangas deslizantes) are fixed. It also has multiple, mirror-smooth journals where the “freewheeling” driven gears ride on needle bearings. The front “nariz” of this shaft fits into the “pilot bushing” (1701111-A7G) inside the input shaft, ensuring perfect alignment. A bent or twisted main shaft will cause catastrophic gear failure, making the integrity of the Conjunto de doble eje FAW supremo.

el núcleo “lógica” del Conjunto de doble eje FAW es su “constant-mesh” diseño. This parts list details all the “conducido” engranajes, which are in permanent, malla constante con el “conducir” gears on the counter-shaft. Estos engranajes son:

When the truck is in neutral, the clutch is engaged, and the input shaft is spinning the counter-shaft. This means all of these driven gears are *also* spinning, but because they ride on bearings on the ‘Second shaft’, ellos son “freewheeling.” They are not locked to the Conjunto de doble eje FAW, so no power is transmitted.

Cuando el conductor selecciona una marcha (P.EJ., 3tercero), the shift fork moves a ‘Sliding sleeve’ (1701316-A7G), which locks the ‘Third gear-second shaft’ (1701366-A9K) hacia Conjunto de doble eje FAW. At that moment, power flows from the counter-shaft, through the 3rd gear pair, and onto the Conjunto de doble eje FAW (main shaft), which then spins at the 3rd gear ratio. All other gears on the shaft continue to freewheel.

El “lógica” of gear selection in the Conjunto de doble eje FAW is performed by the ‘Sliding sleeve’ (1701316-A9K) and ‘Sliding sleeve’ (1701316-A7G) unidades. La lista pide un total de cuatro (one -A9K, three -A7G). These are the synchronizer hubs.

Each sliding sleeve is what the driver’s shift fork physically moves. The *inside* of the sleeve is splined and is permanently locked to the Conjunto de doble eje FAW (main shaft). The *outside* of the sleeve is a groove for the shift fork. When the driver moves the shifter, this sleeve slides “adelante” o “hacia atrás” on the shaft.

The sides of the sleeve, and the sides of the freewheeling gears, have a set of “dientes de perro” (o “clutching teeth”). When the sleeve slides over, its internal teeth engage with the dog teeth on the side of the gear. This creates a solid, bloqueo positivo, forcing the freewheeling gear to spin at the same speed as the Conjunto de doble eje FAW.

To prevent a “molienda” cambio, this sleeve assembly also contains a “sincronizador” (o “anillo bloqueador”). This is a tapered bronze ring that acts as a small, cone-shaped clutch. As the sleeve moves forward, it first pushes this bronze ring onto a matching cone on the gear. The friction between the two instantly equalizes the speed of the sleeve (spinning at shaft speed) and the gear (freewheeling at a different speed). Once their speeds are matched, the sleeve can slide over the dog teeth smoothly and silently. Este “sync-then-lock” logic is the genius of the Conjunto de doble eje FAW.

A constant-mesh gearbox requires perfect alignment. Los engranajes en el Conjunto de doble eje FAW must be perfectly aligned with their counterparts on the counter-shaft. This alignment, o “juego final,” is controlled by a system of precision washers and circlips.

The parts list calls for five ‘Limit washer – engranaje’ (1701327-A7G) and three ‘Inter-shaft limit washer’ (1701318-A9K/A7G). These are not standard washers. Ellos son “cuñas”—hardened, precision-ground washers of a very specific thickness. They are placed between the freewheeling gears and their synchronizer hubs to control the “juego final” (the fore-and-aft slop).

Similarmente, the ‘Locating retaining ring-reverse gear’ (1701312-A7G) and ‘Limit washer-reverse gear’ (1701313-A7G) are a matched set. They work together to lock the ‘Reverse gear-second shaft’ (1701311-A7G) in its exact position on the Conjunto de doble eje FAW, ensuring it aligns perfectly with its idler gear.

The ‘Three-sided key’ (1701396-A9K) and its ‘Circlip’ (1701333-A7G) are used to permanently lock a main synchronizer hub to the Conjunto de doble eje FAW, while the ‘Spring dowel pin’ (Q5280310) is likely used to lock a shaft or pin in place. This entire system of small parts is what guarantees the quiet, long-lasting, and precise operation of the Conjunto de doble eje FAW.

La siguiente tabla proporciona la información completa, desglose detallado de todos 17 components identified in the ‘Dual-Axis (Second Shaft) Asamblea’ diagrama para el tractor FAW CA4251P66K24T1A3E5. Una reconstrucción del Conjunto de doble eje FAW requires meticulous attention to the placement of each washer and circlip.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1701301-A9K | Segundo eje | 1 |

| 2 | 1701396-A9K | Three-sided key | 1 |

| 3 | Q5280310 | pasador de resorte | 1 |

| 4 | 1701333-A7G | Circlip-three-sided key | 1 |

| 5 | 1701312-A7G | Locating retaining ring – marcha atrás | 1 |

| 6 | 1701313-A7G | Limit washer – marcha atrás | 1 |

| 7 | 1701311-A7G | Reverse gear – segundo eje | 1 |

| 8 | 1701316-A9K | Sliding sleeve – contrarrestar | 1 |

| 9 | 1701318-A9K | Inter-shaft limit washer | 1 |

| 10 | 1701326-A9K | Primera marcha – segundo eje | 1 |

| 11 | 1701327-A7G | Limit washer – engranaje | 5 |

| 12 | 1701316-A7G | Sliding sleeve | 3 |

| 13 | 1701356-A9K | Segunda marcha – segundo eje | 1 |

| 14 | 1701318-A7G | Inter-shaft limit washer | 2 |

| 15 | 1701366-A9K | Tercera marcha – segundo eje | 1 |

| 16 | 1701386-A9K | cuarta marcha – segundo eje | 1 |

| 17 | 1701323-A1K | Quinta marcha – segundo eje | 1 |

Las especificaciones para el Conjunto de doble eje FAW are defined by its function as the transmission’s main output shaft, which holds all the freewheeling “conducido” gears and the synchronizer hubs. The proper shimming of the Conjunto de doble eje FAW es critico.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Conjunto de doble eje FAW (Eje principal) |

| Nombre común | Second Shaft / Main Shaft Assembly |

| N/P del eje principal | 1701301-A9K |

| Tipo de sistema | Malla constante, Synchronized |

| Driven Gears | 1calle, 2Dakota del Norte, 3tercero, 4th, 5th, y revertir |

| Gear Actuators | 4x Sliding Sleeves (Synchronizer Hubs) |

| Alignment Control | Limit Washers (cuñas) and Retaining Rings |

| Shaft Locking | Keys (Woodruff, Departamento) and Pins |

| Función primaria | To carry all freewheeling “conducido” gears and be locked to the selected gear via a sliding sleeve, transmitting power to the output. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.