Welcome to this complete technical analysis of the FAW Dual-Axis Assembly, also known as the transmission main shaft or “second shaft,” for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This component is the primary output shaft of the transmission’s main box.

The FAW Dual-Axis Assembly is responsible for holding all the “driven” gears (1st, 2nd, 3rd, 4th, 5th, and reverse) and the synchronizer “sliding sleeves” that lock them in place. It receives torque from the counter-shaft and transmits the selected gear ratio to the truck’s driveline.

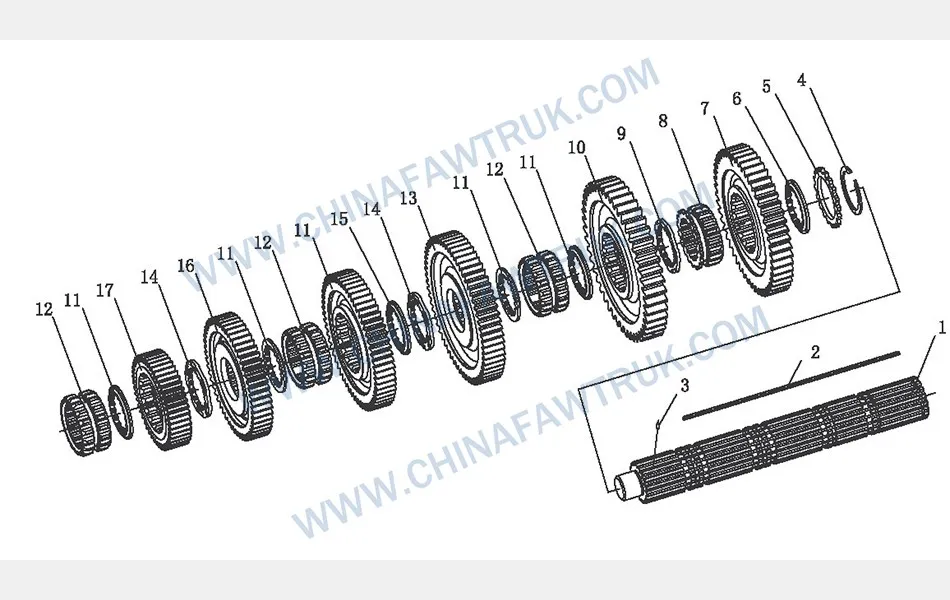

This guide is an essential resource for professional transmission rebuilders and parts specialists. We will deconstruct the entire FAW Dual-Axis Assembly into its 17 serviceable components, including the main shaft (1701301-A9K), all individual helical gears, the sliding sleeves, and the critical bearings and circlips that maintain perfect alignment.

The backbone of the FAW Dual-Axis Assembly is the ‘Second shaft’ (1701301-A9K), also known as the main shaft. This is a single, massive, forged component made from high-strength, case-hardened steel. It is designed to withstand the full, multiplied torque of the engine’s output.

The function of this shaft is to act as the “output” shaft of the main gearbox. Unlike the counter-shaft (which is always spinning at a fixed ratio to the engine), the FAW Dual-Axis Assembly‘s speed *changes* based on the gear selected.

This shaft is a complex piece of precision machining. It features a long, splined section where the synchronizer hubs (sliding sleeves) are fixed. It also has multiple, mirror-smooth journals where the “freewheeling” driven gears ride on needle bearings. The front “nose” of this shaft fits into the “pilot bushing” (1701111-A7G) inside the input shaft, ensuring perfect alignment. A bent or twisted main shaft will cause catastrophic gear failure, making the integrity of the FAW Dual-Axis Assembly paramount.

The core “logic” of the FAW Dual-Axis Assembly is its “constant-mesh” design. This parts list details all the “driven” gears, which are in permanent, constant mesh with the “drive” gears on the counter-shaft. These gears are:

When the truck is in neutral, the clutch is engaged, and the input shaft is spinning the counter-shaft. This means all of these driven gears are *also* spinning, but because they ride on bearings on the ‘Second shaft’, they are “freewheeling.” They are not locked to the FAW Dual-Axis Assembly, so no power is transmitted.

When the driver selects a gear (e.g., 3rd), the shift fork moves a ‘Sliding sleeve’ (1701316-A7G), which locks the ‘Third gear-second shaft’ (1701366-A9K) to the FAW Dual-Axis Assembly. At that moment, power flows from the counter-shaft, through the 3rd gear pair, and onto the FAW Dual-Axis Assembly (main shaft), which then spins at the 3rd gear ratio. All other gears on the shaft continue to freewheel.

The “logic” of gear selection in the FAW Dual-Axis Assembly is performed by the ‘Sliding sleeve’ (1701316-A9K) and ‘Sliding sleeve’ (1701316-A7G) units. The list calls for a total of four (one -A9K, three -A7G). These are the synchronizer hubs.

Each sliding sleeve is what the driver’s shift fork physically moves. The *inside* of the sleeve is splined and is permanently locked to the FAW Dual-Axis Assembly (main shaft). The *outside* of the sleeve is a groove for the shift fork. When the driver moves the shifter, this sleeve slides “forward” or “backward” on the shaft.

The sides of the sleeve, and the sides of the freewheeling gears, have a set of “dog teeth” (or “clutching teeth”). When the sleeve slides over, its internal teeth engage with the dog teeth on the side of the gear. This creates a solid, positive lock, forcing the freewheeling gear to spin at the same speed as the FAW Dual-Axis Assembly.

To prevent a “grinding” shift, this sleeve assembly also contains a “synchronizer” (or “blocker ring”). This is a tapered bronze ring that acts as a small, cone-shaped clutch. As the sleeve moves forward, it first pushes this bronze ring onto a matching cone on the gear. The friction between the two instantly equalizes the speed of the sleeve (spinning at shaft speed) and the gear (freewheeling at a different speed). Once their speeds are matched, the sleeve can slide over the dog teeth smoothly and silently. This “sync-then-lock” logic is the genius of the FAW Dual-Axis Assembly.

A constant-mesh gearbox requires perfect alignment. The gears on the FAW Dual-Axis Assembly must be perfectly aligned with their counterparts on the counter-shaft. This alignment, or “end-play,” is controlled by a system of precision washers and circlips.

The parts list calls for five ‘Limit washer – gear’ (1701327-A7G) and three ‘Inter-shaft limit washer’ (1701318-A9K/A7G). These are not standard washers. They are “shims”—hardened, precision-ground washers of a very specific thickness. They are placed between the freewheeling gears and their synchronizer hubs to control the “end-play” (the fore-and-aft slop).

Similarly, the ‘Locating retaining ring-reverse gear’ (1701312-A7G) and ‘Limit washer-reverse gear’ (1701313-A7G) are a matched set. They work together to lock the ‘Reverse gear-second shaft’ (1701311-A7G) in its exact position on the FAW Dual-Axis Assembly, ensuring it aligns perfectly with its idler gear.

The ‘Three-sided key’ (1701396-A9K) and its ‘Circlip’ (1701333-A7G) are used to permanently lock a main synchronizer hub to the FAW Dual-Axis Assembly, while the ‘Spring dowel pin’ (Q5280310) is likely used to lock a shaft or pin in place. This entire system of small parts is what guarantees the quiet, long-lasting, and precise operation of the FAW Dual-Axis Assembly.

The following table provides the complete, detailed breakdown of all 17 components identified in the ‘Dual-Axis (Second Shaft) Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. A rebuild of the FAW Dual-Axis Assembly requires meticulous attention to the placement of each washer and circlip.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1701301-A9K | Second shaft | 1 |

| 2 | 1701396-A9K | Three-sided key | 1 |

| 3 | Q5280310 | Spring dowel pin | 1 |

| 4 | 1701333-A7G | Circlip-three-sided key | 1 |

| 5 | 1701312-A7G | Locating retaining ring – reverse gear | 1 |

| 6 | 1701313-A7G | Limit washer – reverse gear | 1 |

| 7 | 1701311-A7G | Reverse gear – second shaft | 1 |

| 8 | 1701316-A9K | Sliding sleeve – reverse | 1 |

| 9 | 1701318-A9K | Inter-shaft limit washer | 1 |

| 10 | 1701326-A9K | First gear – second shaft | 1 |

| 11 | 1701327-A7G | Limit washer – gear | 5 |

| 12 | 1701316-A7G | Sliding sleeve | 3 |

| 13 | 1701356-A9K | Second gear – second shaft | 1 |

| 14 | 1701318-A7G | Inter-shaft limit washer | 2 |

| 15 | 1701366-A9K | Third gear – second shaft | 1 |

| 16 | 1701386-A9K | Fourth gear – second shaft | 1 |

| 17 | 1701323-A1K | Fifth gear – second shaft | 1 |

The specifications for the FAW Dual-Axis Assembly are defined by its function as the transmission’s main output shaft, which holds all the freewheeling “driven” gears and the synchronizer hubs. The proper shimming of the FAW Dual-Axis Assembly is critical.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Dual-Axis Assembly (Main Shaft) |

| Common Name | Second Shaft / Main Shaft Assembly |

| Main Shaft P/N | 1701301-A9K |

| System Type | Constant-Mesh, Synchronized |

| Driven Gears | 1st, 2nd, 3rd, 4th, 5th, and Reverse |

| Gear Actuators | 4x Sliding Sleeves (Synchronizer Hubs) |

| Alignment Control | Limit Washers (Shims) and Retaining Rings |

| Shaft Locking | Keys (Woodruff, Flat) and Pins |

| Primary Function | To carry all freewheeling “driven” gears and be locked to the selected gear via a sliding sleeve, transmitting power to the output. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.