Welcome to this comprehensive technical analysis of the FAW Main Box Centre Shaft Assembly Component, the complete counter-shaft gear cluster for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the literal “workhorse” inside the transmission.

The FAW Main Box Centre Shaft Assembly Component (also known as the counter-shaft) is responsible for taking the single input speed from the engine’s clutch and “splitting” it into multiple gear ratios. It is in constant mesh with the input shaft and the main shaft, handling 100% of the engine’s torque.

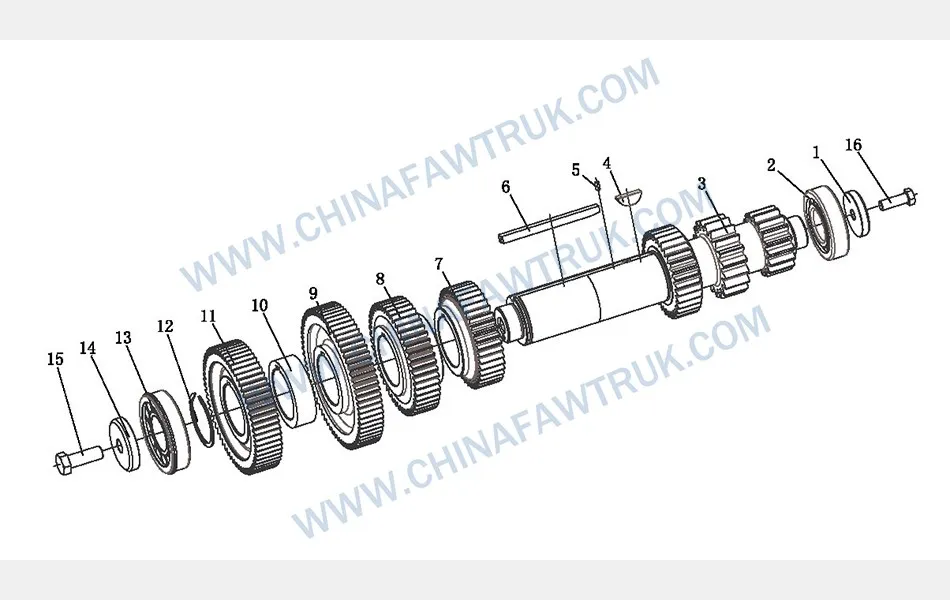

This in-depth guide is an essential resource for professional transmission rebuilders and parts specialists. We will deconstruct the entire FAW Main Box Centre Shaft Assembly Component into its 16 serviceable parts, including the main shaft, all drive gears, the critical bearings, and the hardware that holds it all in perfect alignment.

The backbone of the FAW Main Box Centre Shaft Assembly Component is the ‘Countershaft’ (1701211-A9P) itself. This is a single, massive, forged component made from high-carbon, case-hardened steel. It is designed to be the primary torque-bearing shaft in the transmission.

Its function is to “counter” the rotation of the input shaft. The input shaft’s gear (1701121-A0L, from the previous assembly) is in constant, permanent mesh with one of the gears on this FAW Main Box Centre Shaft Assembly Component. This means that any time the clutch is engaged and the engine is spinning, this countershaft is also spinning.

The shaft itself is precision-machined with multiple “steps,” splines, and bearing journals. The splines are used to mount the various drive gears, while the journals provide a mirror-smooth, ultra-hard surface for the main roller bearings to ride on. A bent or twisted countershaft is a catastrophic failure that requires a full transmission rebuild, making the integrity of this core FAW Main Box Centre Shaft Assembly Component absolutely critical.

The “logic” of the FAW Main Box Centre Shaft Assembly Component is embodied in its drive gears. This parts list details the main set of constant-mesh gears:

These are the “drive” gears. They are fixed (splined or press-fit) to the countershaft and are *always* spinning at the same speed as the countershaft. They are in permanent, constant mesh with their corresponding “driven” gears, which spin freely on the main shaft. When the driver selects “3rd gear,” they are actually engaging a clutch (a “synchronizer”) that locks the *freewheeling 3rd gear* to the main shaft. The power flow is then from the input gear, to the FAW Main Box Centre Shaft Assembly Component, through this ‘3rd gear-countershaft’ (1701212-A9K), to the main shaft, and out to the wheels.

These gears are “helically cut” (with angled teeth). This is a critical design choice for a heavy-duty FAW Main Box Centre Shaft Assembly Component. The angled teeth engage gradually and smoothly, which is far quieter than “straight-cut” spur gears. This design also allows for more than one tooth to be in contact at any given time, spreading the immense torque load over a wider surface area and providing superior strength.

The ‘Reduction gear-countershaft’ (1701217-A0L) is another critical drive gear within the FAW Main Box Centre Shaft Assembly Component. This is typically the “low” or “creeper” gear, providing the maximum torque multiplication for starting the truck from a dead stop, especially on a hill.

This gear must be precisely located on the shaft. This is the job of the ‘Spacer’ (1701247-A7K) and the ‘Circlip-reduction gear’ (1701229-A7G). The spacer is a hardened steel sleeve that provides the correct “stand-off” distance from the other gears, while the circlip (a “snap ring”) fits into a groove on the shaft to lock the gear in its final fore-and-aft position.

This FAW Main Box Centre Shaft Assembly Component is held together by various keys, including the ‘Woodruff Key’ (1701226-A7G) and ‘Flat Key’ (1701228-A7G). These small steel parts sit in a slot on the shaft and a corresponding slot in the gear, physically locking the two together to transfer all rotational torque. The ‘Spring Dowel Pin’ (Q5280510) is also used to pin one of the components, like the spacer, in place.

The entire FAW Main Box Centre Shaft Assembly Component spins at engine speed, supported at both ends by massive bearings that are pressed into the transmission housing.

**Front Bearing (NU309NRB1/YA6):** This is the ‘Cylindrical roller bearing with stop ring’. This heavy-duty roller bearing supports the front of the countershaft. It is designed to handle extreme *radial* loads (the separating force from the gears). The “stop ring” (a circlip on its outer race) is critical, as it locks the bearing into the transmission case, setting the “end-play” for the entire FAW Main Box Centre Shaft Assembly Component.

**Rear Bearing (1701235-A9P):** This is the ‘Cylindrical roller bearing’ that supports the rear of the shaft. It sits in a precision-bored hole in the mid-housing.

**Baffles (1701233-A7G / 1701233-A9P):** These bearings are protected by the ‘Baffle-countershaft front bearing’ and ‘Baffle-countershaft rear bearing’. These are “slinger” discs. As the transmission’s gear oil is violently splashed around, these baffles, which spin with the shaft, sling the oil *away* from the bearing seals. This prevents them from being overwhelmed and failing, which would allow the gear oil to leak out and the bearing to run dry. This is a critical durability feature of the FAW Main Box Centre Shaft Assembly Component, and these baffles are secured by the ‘Hex head bolts’ (CQ1511645S, CQ1511235S).

The following table provides the complete, detailed breakdown of all 16 components identified in the ‘Main Box Centre Shaft Assembly Component’ diagram for the FAW CA4251P66K24T1A3E5 tractor. The proper assembly of this FAW Main Box Centre Shaft Assembly Component is key to a quiet, reliable transmission.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1701233-A9P | Baffle – countershaft rear bearing | 1 |

| 2 | 1701235-A9P | Cylindrical roller bearing | 1 |

| 3 | 1701211-A9P | Countershaft | 1 |

| 4 | 1701226-A7G | Woodruff key | 1 |

| 5 | Q5280510 | Spring dowel pin | 1 |

| 6 | 1701228-A7G | Flat key | 1 |

| 7 | 1701212-A9K | 3rd gear-countershaft | 1 |

| 8 | 1701213-A9K | 4th gear-countershaft | 1 |

| 9 | 1701214-A1K | 5th gear-countershaft | 1 |

| 10 | 1701247-A7K | Spacer | 1 |

| 11 | 1701217-A0L | Reduction gear-countershaft | 1 |

| 12 | 1701229-A7G | Circlip-reduction gear | 1 |

| 13 | NU309NRB1/YA6 | Cylindrical roller bearing with stop ring | 1 |

| 14 | 1701233-A7G | Baffle-countershaft front bearing | 1 |

| 15 | CQ1511645S | Hex head bolt | 1 |

| 16 | CQ1511235S | Hex head bolt | 1 |

The specifications for the FAW Main Box Centre Shaft Assembly Component are defined by its function as the core, torque-handling gear cluster of the transmission. The entire FAW Main Box Centre Shaft Assembly Component is a precision-balanced and matched set.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Main Box Centre Shaft Assembly Component |

| Common Name | Countershaft Assembly / Intermediate Shaft |

| Main Shaft P/N | 1701211-A9P |

| Gear Set | 3rd (A9K), 4th (A9K), 5th (A1K), Reduction (A0L) |

| Gear Type | Constant-Mesh, Helical-Cut |

| Front Bearing P/N | NU309NRB1/YA6 (Roller Bearing w/ Stop Ring) |

| Rear Bearing P/N | 1701235-A9P (Cylindrical Roller Bearing) |

| Bearing Protection | Front (A7G) & Rear (A9P) Baffles |

| Primary Function | To receive input torque and create multiple gear ratios by driving the main shaft gears. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.