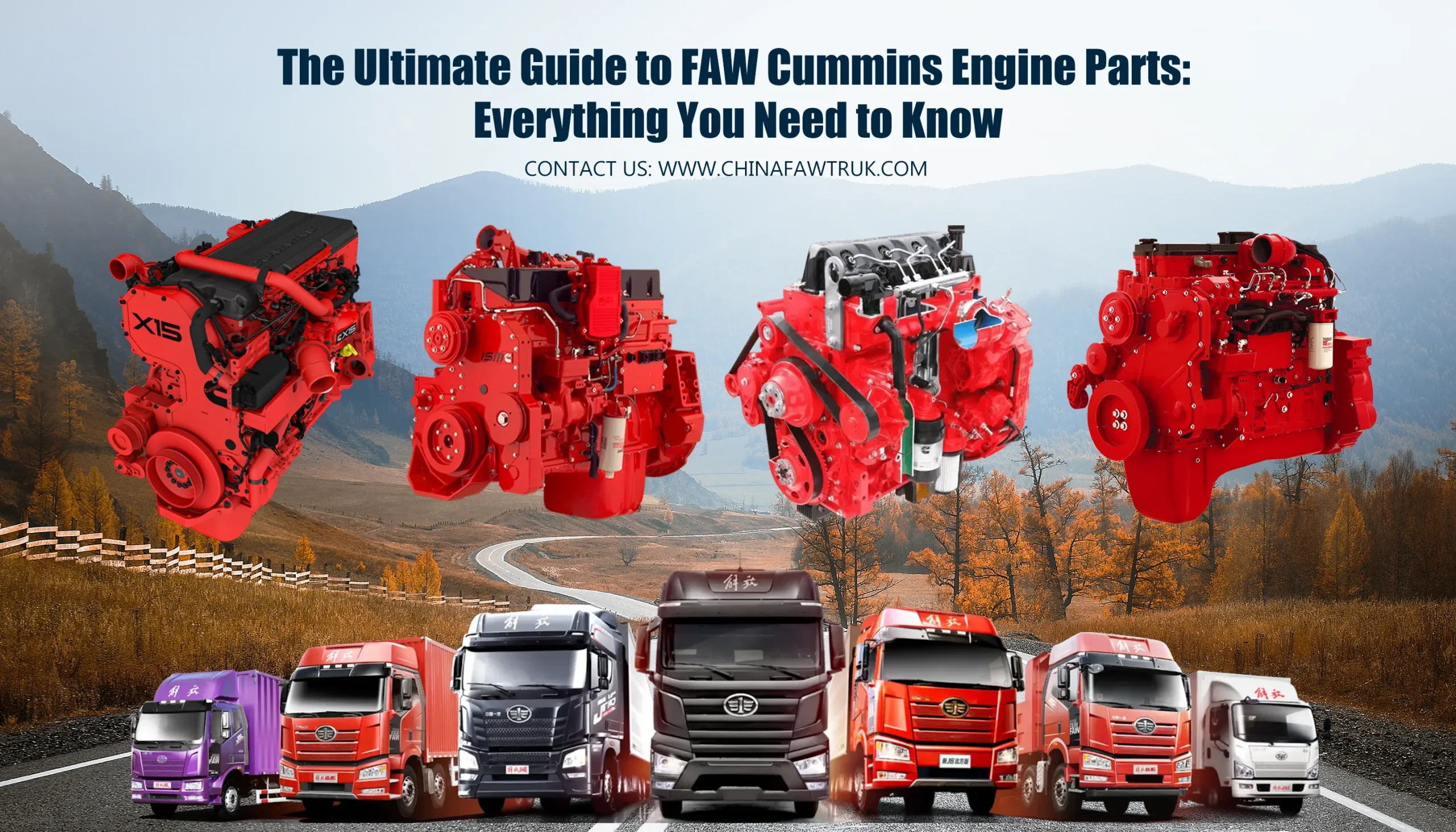

The marriage of FAW’s automotive expertise and Cummins’ powertrain innovation has created engines specifically designed to meet the demanding requirements of modern transportation while adhering to increasingly stringent emission standards. These engines are renowned for their durability, fuel efficiency, and low total cost of ownership , making them popular choices for fleet operators and owner-drivers alike.

In this comprehensive guide, we’ll explore the world of FAW Cummins engine parts , examining common engine models, frequently replaced components, maintenance strategies, and how to identify genuine parts. Whether you’re a distributor, mechanic, or fleet manager, this information will help you better understand these sophisticated powerplants and make informed decisions about their maintenance and repair.

FAW trucks utilize several Cummins engine series, each designed for specific applications and performance requirements. Understanding these different models is crucial for identifying the correct FAW Cummins engine parts when maintenance is required.

The ISF series represents Cummins’ light-duty engine platform, with displacements ranging from 2.8L to 4.5L. These compact yet powerful engines are found in FAW’s light and medium-duty trucks, offering an excellent balance of performance and efficiency. The ISF2.8 and ISF3.8 models are particularly popular in urban delivery vehicles and smaller utility trucks where packaging constraints and maneuverability are important considerations.

These engines feature advanced turbocharging technology , high-pressure common rail fuel systems , and modern emission control systems that make them compliant with worldwide emission standards. Despite their relatively small displacement, these engines deliver impressive torque characteristics ideal for stop-start urban cycles and highway cruising alike.

The 8.9L ISL engine serves medium-duty applications in FAW trucks requiring more power for regional hauling and specialized vocations. This engine strikes a balance between size, weight, and performance, making it versatile for various truck configurations. With power ratings typically ranging from 300 to 380 horsepower, the ISL provides ample power for distribution trucks, refrigerated transport, and even smaller dump trucks.

The ISL incorporates innovative combustion technology and advanced air handling systems to optimize fuel economy across its operating range. Its compact design also simplifies installation in chassis with space constraints while maintaining serviceability for routine maintenance tasks.

The latest FAW heavy-duty trucks are available with Cummins’ X Series engines, including the X12 and X15 models. These advanced engines incorporate cutting-edge efficiency technologies and connected features that optimize performance and provide valuable operational insights. With displacements of 11.8L and 14.9L respectively, these engines meet the most stringent global emission standards while delivering class-leading fuel economy.

The X Series engines feature connected digital capabilities that enable remote programming, proactive maintenance alerts, and performance optimization based on actual operating conditions. These technologies represent the future of commercial diesel engines and highlight the continuous innovation in FAW Cummins engine parts and systems.

For more demanding applications, FAW’s heavy-duty trucks often feature the Cummins ISM 10.8L engine. This proven heavy-duty platform delivers reliable performance in long-haul, construction, and vocational applications where durability and uptime are critical. With power ratings typically between 330 and 450 horsepower, the ISM provides the necessary performance for gross combination weights up to 120,000 pounds in some configurations.

The ISM features robust architecture designed for extended service intervals and minimal life-cycle costs . Its reputation for reliability has made it a preferred choice for operators in emerging markets where maintenance infrastructure may be limited and operating conditions can be challenging.

Maintaining FAW Cummins engines requires understanding which components most commonly need replacement. Whether due to regular wear, operating conditions, or scheduled maintenance, certain FAW Cummins engine parts are replaced more frequently than others. Here are six of the most commonly replaced components:

Fuel injectors are precision components that deliver exactly the right amount of atomized fuel into the combustion chamber at precisely the right time.

Regular fuel filter changes using quality filters are essential for maximizing injector life.

Typical symptoms of failing injectors include:

– Hard starting or extended cranking

– Rough idle or misfiring

– White or black exhaust smoke

– Reduced power and fuel economy

– Increased emissions

Air filtration is critical for engine longevity, especially in dusty or polluted environments. FAW Cummins engine parts in the intake system include air filters, intake pipes, and sometimes charge air coolers. These components protect the engine from abrasive particles that can cause rapid wear of internal components.

Air filters require regular inspection and replacement according to service intervals or restriction indicators. Neglecting air filter maintenance can lead to:

– Increased engine wear

– Reduced performance and fuel economy

– Turbocharger damage

– Increased emissions

Clean oil is the lifeblood of any diesel engine, and the filtration system is essential for maintaining oil quality. FAW Cummins engine parts related to lubrication include oil filters, oil coolers, and various seals and gaskets.Using the recommended oil grade and quality, along with timely filter changes, significantly extends engine life and reduces the frequency of more expensive repairs.

Common lubrication system issues include:

– Oil leaks from seals and gaskets

– Clogged oil coolers reducing cooling efficiency

– Bypassing filters that allow contaminated oil to circulate

Turbochargers increase engine efficiency and power output by forcing more air into the combustion chambers. FAW Cummins engine parts in the turbocharger system include the turbo itself, wastegate actuators, piping, and intercoolers. These components operate under extreme temperatures and pressures, making them susceptible to wear and failure.

When failures occur, they often necessitate not just turbocharger replacement but also thorough cleaning of the intake and oil systems to remove debris.

Common turbocharger issues include:

– Shaft play and bearing wear

– Carbon buildup causing sticking vanes

– Cracked housings or heat shields

– Boost leaks in piping and connections

Emission control systems, particularly Exhaust Gas Recirculation (EGR) systems, contain several components that require regular attention on modern FAW Cummins engines. FAW Cummins engine parts in the EGR system include coolers, valves, pipes, and associated sensors. These components handle hot, sooty exhaust gases that can lead to clogging and corrosion over time.

Common EGR system maintenance issues include:

– Clogged EGR coolers reducing efficiency

– Sticking EGR valves causing performance issues

– Leaks in EGR piping affecting engine operation

– Sensor failures triggering fault codes

The cooling system is vital for regulating engine temperature and preventing overheating damage. FAW Cummins engine parts in the cooling system include water pumps, thermostats, hoses, and radiators. These components are subject to thermal cycling, pressure stress, and chemical degradation from coolant additives.

Water pumps in particular are wear items that typically require replacement at certain mileage intervals. Symptoms of cooling system issues include:

– Coolant leaks from seals or connections

– Overheating or difficulty maintaining temperature

– Reduced heater performance

– Coolant contamination from internal leaks

Regular coolant analysis and changes help prolong the life of cooling system components by maintaining proper chemical balance and preventing corrosion or scale formation.

Beyond the regularly replaced maintenance items, certain FAW Cummins engine parts are more vulnerable to wear or damage based on operating conditions, maintenance practices, and design characteristics. Understanding these vulnerabilities helps in planning maintenance programs and stocking appropriate inventory.

Following recommended preventive maintenance intervals for FAW Cummins engine parts is the foundation of a reliable maintenance program. Key aspects include:

– Adhering to oil and filter change intervals based on operating conditions

– Inspecting air restriction indicators and replacing filters as needed

– Checking coolant concentration and condition at regular intervals

– Inspecting belts and hoses for signs of wear or deterioration

– Performing valve lash adjustments at specified intervals where required

Maintenance intervals should be adjusted based on actual operating conditions, with more frequent service recommended for severe applications such as extreme temperatures, dusty environments, or frequent idling.

Getting parts to you intact requires military-grade precision

Bombproof Packaging Methods

– Steering/Suspension Parts :

– VCI-coated paper wrap + edge guards + molded EPS foam.

– Palletizing : DP016 boxes (1160x1020x1220mm) on TP02 pallets (1000x1200mm).

– Engine Assemblies (e.g., 465Q1A) :

– Steel banding to 4″ hardwood skids with corner posts.

– Max Weight : 355kg – threshold for container floor loading.

– Transmission Housings :

– Custom wooden crates (120x80x60cm) with internal bracing against casting lugs.

Shipping Strategies That Slash Costs

– For Orders < 100 Sets : Air freight sensors/ECUs via DDP to clear customs fast.

– Full Container Loads (FCL) :

– Optimization : Stack DP015 boxes (760x1020x1220mm) in 40ft HC containers – fits 72% more than loose loading.

Contact us for a customized FAW truck and parts recommendation!

FAW is one of China’s oldest and largest automotive manufacturers, with registered capital of RMB 35.4 billion yuan and total assets of RMB 457.83 billion yuan.

CHINA FAW GROUP CO., LTD. (short for FAW), formerly China First Automobile Works, can trace its roots back to Jul 15, 1953, when its first assembly plant started to be constructed. FAW is one of China’s oldest and largest automotive manufacturers, with registered capital of RMB 35.4 billion yuan and total assets of RMB 457.83 billion yuan.

China heavy truck sales global “five in a row”, heavy truck sales global “six in a row”, tractor sales for 16 consecutive years absolute leading industry.

{FAW}

We will contact you immediately

Hello, what VIN code for Faw J6 or J7 parts do you need?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us

Send your inquiry / assessment to Us. Anything need us ,please don’t hesitate contact us here! we will keep it secret for you !