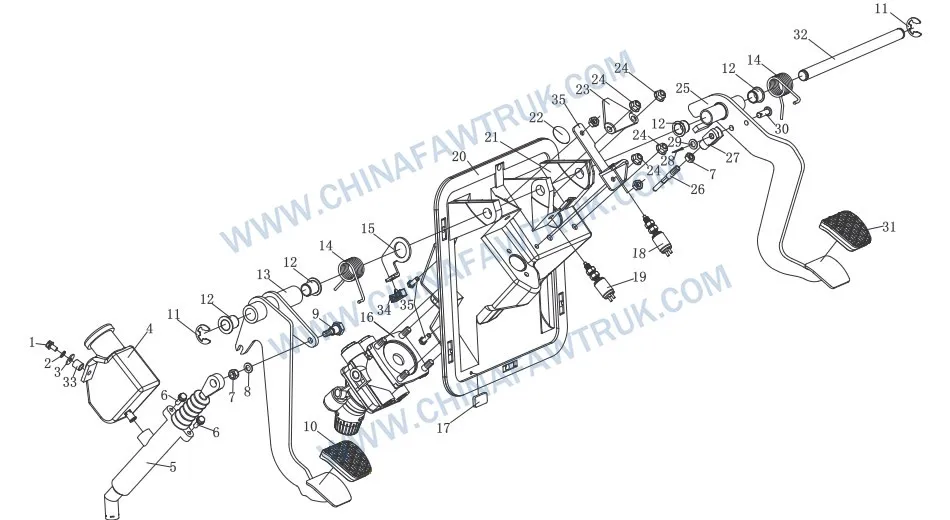

Pédale d'embrayage avec maître-cylindre: Maîtriser 35 Pièces stratégiques pour un changement de vitesse de précision dans l'Arctique

Le Pédale d'embrayage avec maître-cylindre L'assemblage est le cœur cinétique du système de commande de la transmission du camion-benne FAW CA3250P66K24L1TE5Z.. Conçu spécifiquement pour les exigences extrêmes de la zone froide russe, ce module traduit l'intention du conducteur en un actionnement hydraulique transparent, garantissant des changements de vitesse fiables même lorsque les températures chutent jusqu'à -50°C. En intégrant un réservoir de grande capacité avec un mécanisme de pédale robuste, le Pédale d'embrayage avec maître-cylindre Le système garantit que les opérateurs de flotte conservent le contrôle total de leur transmission dans les environnements miniers les plus difficiles.

Pédale d'embrayage avec maître-cylindre

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | CQ1740635 | Boulon à tête hexagonale avec fente | 1 |

| 2 | Q40406 | Laveuse à ressort léger | 1 |

| 3 | Q40206 | Grande laveuse | 1 |

| 4 | 1602100-50UN | Ensemble de réservoir d'huile (Échantillon) | 1 |

| 5 | 1602110-76W | Ensemble de maître-cylindre d'embrayage (Échantillon) | 1 |

| 6 | CQ1460620 | Boulon combiné | 2 |

| 7 | CQ34008 | Écrou hexagonal | 1 |

| 8 | Q40308 | Rondelle à ressort | 1 |

| 9 | 1602091-50UN | Arbre – Maître Cylindre | 1 |

| 10 | 1602037-50UN | Bague pédale | 1 |

| 11 | Q436150 | Anneau de retenue ouvert | 2 |

| 12 | 3504061-50UN | Bague – Arbre de pédale de frein | 4 |

| 13 | 1602020-76W | Ensemble de pédale d'embrayage | 1 |

| 14 | 3504036-50UN | Retour printemps – Pédale de frein | 2 |

| 15 | 1602027-76W | Culbuteur – Commutateur d'embrayage | 1 |

| 16 | 3514010-50UN | Ensemble de valve de frein et de joint de tuyau | 1 |

| 17 | 1602092-50UN | Bloc de limite de pédale | 1 |

| 18 | 3754030-76W | Ensemble de commutateur d'embrayage | 1 |

| 19 | 3720010-A01 | Ensemble de commutateur de feu stop | 1 |

| 20 | 3504033-50UN | Joint – Ensemble de pédale | 1 |

| 21 | 3504031-76W | Support de pédale | 1 |

| 22 | 3504038-50UN | Tampon – Bras de pédale de frein | 1 |

| 23 | 3504037-50UN | Plaque – Bras de pédale de frein | 1 |

| 24 | CQ32608 | Contre-écrou à bride hexagonale | 4 |

| 25 | 3504070-50UN | Ensemble de pédale de frein | 1 |

| 26 | 3504063-50UN | Tige de poussée | 1 |

| 27 | 3504062-50UN | Fourche filetée – Pédale de frein | 1 |

| 28 | Q5002016 | Goupille fendue | 1 |

| 29 | Q40108 | Machine à laver | 1 |

| 30 | Q5100825 | Goupille à tête plate | 1 |

| 31 | 3504074-50UN | Bague pédale | 1 |

| 32 | 3504032-50UN | Arbre de pédale | 1 |

| 33 | 1602102-76W | Manche – Coupe d'huile d'embrayage | 1 |

| 34 | 1602038-76W | Bloc limite – Pédale d'embrayage | 1 |

| 35 | 1602250-76W | Ensemble de support de commutateur d'embrayage | 1 |

| – | CQ1500620 | Boulon à tête hexagonale | 2 |

| – | Q40306 | Rondelle à ressort | 2 |

Architecture hydraulique: Le cœur de la performance par temps froid

La conception d'une interface de transmission fiable pour l'Arctique russe nécessite une base hydraulique robuste. Au centre de la FAW Pédale d'embrayage avec maître-cylindre l'assemblage est le Ensemble de maître-cylindre d'embrayage (Partie no. 1602110-76W). Contrairement aux cylindres standards qui peuvent souffrir d'un retrait du joint à des températures inférieures à zéro., ce composant utilise des élastomères synthétiques à basse température. Ces joints avancés maintiennent une pression positive même à -50°C, garantissant que l'action du pied du conducteur se traduit instantanément par un désengagement de l'embrayage sans la sensation spongieuse associée au fluide contournant le piston.

Alimenter ce système est le Ensemble de réservoir d'huile (Partie no. 1602100-50UN). Dans le Pédale d'embrayage avec maître-cylindre mise en page, ce réservoir est stratégiquement monté en hauteur sur le Support de pédale (Partie no. 3504031-76W) utiliser la gravité pour l'amorçage du fluide. Le matériau du réservoir est un matériau à fort impact, polymère translucide résistant à la dégradation UV et aux cycles thermiques extrêmes. Cela permet une inspection visuelle rapide des niveaux de liquide, une tâche de maintenance quotidienne critique dans les opérations minières où l'ouverture du système hydraulique aux éléments introduit un risque de contamination par l'humidité et de gel ultérieur.

La connexion entre la pédale et le vérin hydraulique est gérée par le Arbre – Maître Cylindre (Partie no. 1602091-50UN). Cet arbre doit supporter des milliers de cycles d'actionnement par équipe. Dans le Pédale d'embrayage avec maître-cylindre système, l'arbre est durci pour éviter l'usure et les rayures, ce qui pourrait entraîner des fuites de liquide. L'ensemble est sécurisé par un spécialiste Manche – Coupe d'huile d'embrayage (Partie no. 1602102-76W), garantir que le réservoir reste stable malgré les vibrations intenses typiques d'un camion-benne lourd circulant sur des routes difficiles.

Mécanique des pédales: Ergonomie et durabilité

L'interface mécanique du Pédale d'embrayage avec maître-cylindre l'assemblage est défini par le Ensemble de pédale d'embrayage (Partie no. 1602020-76W). Ce composant est forgé pour une rigidité maximale, empêchant le bras de la pédale de fléchir sous une forte pression du pied. La géométrie des pédales est optimisée pour la cabine J6P, offrant un ratio de levier qui réduit la fatigue du conducteur lors des changements de vitesse fréquents. Le point pivot repose sur le Arbre de pédale (Partie no. 3504032-50UN), un composant rectifié avec précision qui assure une douceur, rotation sans blocage tout au long de l'arc de déplacement de la pédale.

Pour maintenir ce bon fonctionnement dans des conditions de gel, le Pédale d'embrayage avec maître-cylindre le système utilise des lubrifiants autolubrifiants Bague pédale unités (Partie no. 1602037-50UN). Les pivots métal sur métal traditionnels peuvent se gripper lorsque la graisse s'épaissit à froid, mais ces bagues composites maintiennent un faible coefficient de frottement quelle que soit la température ambiante. En outre, le Bloc limite – Pédale d'embrayage (Partie no. 1602038-76W) agit comme une butée cruciale. Cet isolateur en caoutchouc amortit la pédale en bas de sa course, prévenir la fatigue du métal et réduire le bruit dans la cabine, contributing to a more comfortable operator environment.

The return action of the pedal is governed by the Retour printemps – Pédale de frein (Partie no. 3504036-50UN), which is shared within the bracket assembly. Dans le contexte du Pédale d'embrayage avec maître-cylindre, this spring ensures the pedal snaps back to its rest position immediately after the driver releases pressure. A weak or frozen spring can lead to partial clutch engagement, causing rapid wear of the clutch friction disc. FAW’s selection of cold-resistant spring steel ensures this critical component retains its elasticity even after an overnight soak in Siberian winter conditions.

Safety Interlocks: The Role of the Clutch Switch

Modern heavy trucks integrate mechanical control with electronic safety systems, et le Pédale d'embrayage avec maître-cylindre assembly is no exception. A key component here is the Ensemble de commutateur d'embrayage (Partie no. 3754030-76W). This switch serves a vital safety function: il empêche le moteur de démarrer à moins que la pédale d'embrayage ne soit complètement enfoncée. Ce verrouillage garantit que le camion ne peut pas avancer accidentellement s'il est démarré alors qu'il est en prise., un élément de sécurité essentiel pour les sites miniers où le personnel peut travailler à proximité du véhicule.

L'actionnement précis de cet interrupteur est géré par le Culbuteur – Commutateur d'embrayage (Partie no. 1602027-76W) et le Ensemble de support de commutateur d'embrayage (Partie no. 1602250-76W). Au sein du Pédale d'embrayage avec maître-cylindre architecture, ces composants alignent le mouvement mécanique du bras de la pédale avec le contact électrique de l'interrupteur. Un mauvais alignement ici peut conduire à “pas de démarrage” conditions ou non-désengagement du régulateur de vitesse. Le support est conçu pour être rigide et résistant aux vibrations, maintenir cet alignement précis tout au long de la durée de vie du véhicule.

En outre, les signaux générés par le Pédale d'embrayage avec maître-cylindre l'ensemble interagit avec l'unité de commande du moteur (ECU) pour gérer la sortie de couple pendant les changements de vitesse. Les changements de vitesse en douceur protègent la transmission de la transmission des charges de choc. La fiabilité du Ensemble de commutateur d'embrayage est primordial; donc, il est logé dans un boîtier étanche pour protéger les contacts internes de la condensation qui se forme inévitablement à l'intérieur de la cabine chaude lorsque la température extérieure est bien en dessous de zéro, assurer une continuité électrique constante pour le Pédale d'embrayage avec maître-cylindre système.

Intégrité de l'installation: Fixations et entretien

L'intégrité structurelle du Pédale d'embrayage avec maître-cylindre s'appuie sur un ensemble spécifique de fixations haute résistance. L'ensemble est ancré au pare-feu à l'aide du Boulon à tête hexagonale avec fente (Partie no. CQ1740635) et Boulon combiné (Partie no. CQ1460620). Ce ne sont pas du matériel standard; ils sont conçus pour résister aux forces de cisaillement générées lorsqu'un conducteur applique toute sa force sur la pédale en cas d'urgence. L'utilisation d'un Contre-écrou à bride hexagonale (Partie no. CQ32608) répartit la charge de serrage et empêche le desserrage dû aux vibrations à haute fréquence du moteur diesel.

Un bon entretien du Pédale d'embrayage avec maître-cylindre implique une inspection régulière des points d’arrimage. Les mécaniciens doivent vérifier Anneau de retenue ouvert (Partie no. Q436150) that secures the pedal shaft. If this ring fails, the pedal shaft could migrate, leading to catastrophic loss of clutch control. En plus, le Goupille à tête plate (Partie no. Q5100825) et Goupille fendue (Partie no. Q5002016) used in the linkage must be inspected for corrosion or fatigue, as these small parts are the linchpins of the mechanical connection in the Pédale d'embrayage avec maître-cylindre système.

Enfin, le Pédale d'embrayage avec maître-cylindre assembly includes various washers like the Laveuse à ressort léger (Partie no. Q40406) et Grande laveuse (Partie no. Q40206). These seemingly minor components play a major role in preventing fastener back-off and protecting the painted surfaces of the bracket from corrosion. By using genuine FAW replacement parts for even these small items, fleet managers ensure that the Pédale d'embrayage avec maître-cylindre remains a cohesive, reliable unit capable of enduring the grueling conditions of the Russian heavy transport sector.

Conclusion: The Pinnacle of Drivetrain Control

Le Pédale d'embrayage avec maître-cylindre represents a critical fusion of hydraulic power and mechanical precision. Chaque composant, from the cold-resistant seals in the Ensemble de maître-cylindre d'embrayage à la conception ergonomique du Ensemble de pédale d'embrayage, est conçu pour offrir au conducteur une confiance absolue. Dans l’environnement impitoyable de l’Arctique russe, où une panne d'équipement peut mettre la vie en danger, la conception robuste du Pédale d'embrayage avec maître-cylindre témoigne de l’engagement de FAW en matière de sécurité et de fiabilité.

Pour les équipes de maintenance, en respectant la répartition détaillée des pièces du Pédale d'embrayage avec maître-cylindre est essentiel pour minimiser les temps d’arrêt. Entretien préventif régulier, se concentrer sur les niveaux de liquide, usure des bagues, et couple de fixation, garantit que le système fonctionne de manière optimale. En choisissant des pièces FAW authentiques pour le Pédale d'embrayage avec maître-cylindre, les opérateurs sécurisent la longévité de leur flotte, garantissant que chaque changement de vitesse est aussi fluide et fiable que le premier, quelle que soit la température extérieure.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.