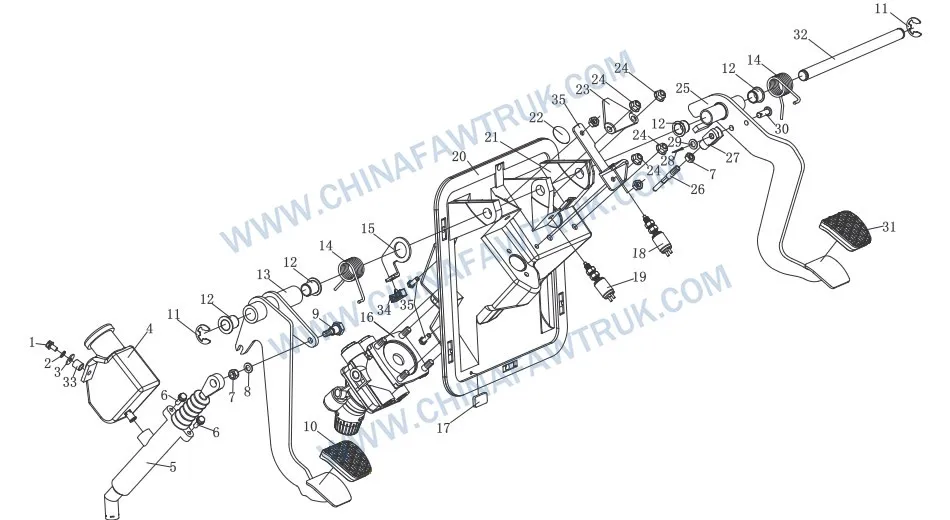

Pedal de embreagem com conjunto de cilindro mestre: Masterização 35 Peças Estratégicas para Mudanças de Precisão no Ártico

O Pedal de embreagem com cilindro mestre assembly is the kinetic heart of the drivetrain control system for the FAW CA3250P66K24L1TE5Z dump truck. Engineered specifically for the extreme demands of the Russian cold zone, this module translates driver intent into seamless hydraulic actuation, ensuring reliable gear changes even when temperatures plummet to -50°C. By integrating a high-capacity reservoir with a ruggedized pedal mechanism, o Pedal de embreagem com cilindro mestre system guarantees that fleet operators maintain full command over their transmission in the toughest mining environments.

Pedal de embreagem com cilindro mestre

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | CQ1740635 | Hexagon Head Bolt with Slot | 1 |

| 2 | Q40406 | Lavadora de mola leve | 1 |

| 3 | Q40206 | Arruela Grande | 1 |

| 4 | 1602100-50A | Oil Reservoir Assembly (Amostra) | 1 |

| 5 | 1602110-76C | Conjunto do cilindro mestre da embreagem (Amostra) | 1 |

| 6 | CQ1460620 | Parafuso de combinação | 2 |

| 7 | CQ34008 | Noz hexágono | 1 |

| 8 | Q40308 | Arruela elástica | 1 |

| 9 | 1602091-50A | Haste – Cilindro mestre | 1 |

| 10 | 1602037-50A | Bucha de pedal | 1 |

| 11 | Q436150 | Anel de retenção aberto | 2 |

| 12 | 3504061-50A | Casquilho – Brake Pedal Shaft | 4 |

| 13 | 1602020-76C | Conjunto do pedal da embreagem | 1 |

| 14 | 3504036-50A | Spring de retorno – Pedal de freio | 2 |

| 15 | 1602027-76C | Rocker Arm – Clutch Switch | 1 |

| 16 | 3514010-50A | Brake Valve and Pipe Joint Assembly | 1 |

| 17 | 1602092-50A | Pedal Limit Block | 1 |

| 18 | 3754030-76C | Conjunto do interruptor da embreagem | 1 |

| 19 | 3720010-A01 | Stop Lamp Switch Assembly | 1 |

| 20 | 3504033-50A | Junta – Pedal Assembly | 1 |

| 21 | 3504031-76C | Pedal Bracket | 1 |

| 22 | 3504038-50A | Almofada – Brake Pedal Arm | 1 |

| 23 | 3504037-50A | Placa – Brake Pedal Arm | 1 |

| 24 | CQ32608 | Porca de travamento de flange hexagonal | 4 |

| 25 | 3504070-50A | Brake Pedal Assembly | 1 |

| 26 | 3504063-50A | Haste | 1 |

| 27 | 3504062-50A | Threaded Fork – Pedal de freio | 1 |

| 28 | Q5002016 | Contrapino | 1 |

| 29 | Q40108 | Máquina de lavar | 1 |

| 30 | Q5100825 | Pino de cabeça plana | 1 |

| 31 | 3504074-50A | Bucha de pedal | 1 |

| 32 | 3504032-50A | Pedal Shaft | 1 |

| 33 | 1602102-76C | Manga – Clutch Oil Cup | 1 |

| 34 | 1602038-76C | Limit Block – Clutch Pedal | 1 |

| 35 | 1602250-76C | Clutch Switch Bracket Assembly | 1 |

| – | CQ1500620 | Parafuso de cabeça hexagonal | 2 |

| – | Q40306 | Arruela elástica | 2 |

Hydraulic Architecture: The Core of Cold Weather Performance

Designing a reliable drivetrain interface for the Russian Arctic requires a robust hydraulic foundation. At the center of the FAW Pedal de embreagem com cilindro mestre a montagem é a Conjunto do cilindro mestre da embreagem (Parte não. 1602110-76C). Unlike standard cylinders that may suffer from seal shrinkage in sub-zero temperatures, this component utilizes low-temperature synthetic elastomers. These advanced seals maintain positive pressure even at -50°C, ensuring that the driver’s foot input is translated instantly into clutch disengagement without the spongy feel associated with fluid bypassing the piston.

Feeding this system is the Oil Reservoir Assembly (Parte não. 1602100-50A). No Pedal de embreagem com cilindro mestre layout, this reservoir is strategically mounted high on the Pedal Bracket (Parte não. 3504031-76C) to utilize gravity for fluid priming. The reservoir material is a high-impact, translucent polymer resistant to UV degradation and extreme thermal cycling. This allows for rapid visual inspection of fluid levels, a critical daily maintenance task in mining operations where opening the hydraulic system to the elements introduces the risk of moisture contamination and subsequent freezing.

The connection between the pedal and the hydraulic cylinder is managed by the Haste – Cilindro mestre (Parte não. 1602091-50A). This shaft must endure thousands of actuation cycles per shift. No Pedal de embreagem com cilindro mestre sistema, the shaft is hardened to prevent wear and scoring, which could lead to fluid leaks. The assembly is secured with a specialized Manga – Clutch Oil Cup (Parte não. 1602102-76C), ensuring the reservoir remains stable despite the intense vibrations typical of a heavy-duty dump truck navigating rough haul roads.

Pedal Mechanics: Ergonomics and Durability

The mechanical interface of the Pedal de embreagem com cilindro mestre assembly is defined by the Conjunto do pedal da embreagem (Parte não. 1602020-76C). This component is forged for maximum rigidity, preventing the pedal arm from flexing under heavy foot pressure. The pedal geometry is optimized for the J6P cabin, providing a leverage ratio that reduces driver fatigue during frequent shifting. The pivot point relies on the Pedal Shaft (Parte não. 3504032-50A), a precision-ground component that ensures smooth, bind-free rotation throughout the pedal’s travel arc.

To maintain this smooth operation in freezing conditions, o Pedal de embreagem com cilindro mestre system utilizes self-lubricating Bucha de pedal unidades (Parte não. 1602037-50A). Traditional metal-on-metal pivots can seize when grease thickens in the cold, but these composite bushings maintain a low coefficient of friction regardless of the ambient temperature. Além disso, o Limit Block – Clutch Pedal (Parte não. 1602038-76C) acts as a crucial bump stop. This rubber isolator cushions the pedal at the bottom of its stroke, preventing metal fatigue and reducing noise in the cabin, contributing to a more comfortable operator environment.

The return action of the pedal is governed by the Spring de retorno – Pedal de freio (Parte não. 3504036-50A), which is shared within the bracket assembly. No contexto do Pedal de embreagem com cilindro mestre, this spring ensures the pedal snaps back to its rest position immediately after the driver releases pressure. A weak or frozen spring can lead to partial clutch engagement, causing rapid wear of the clutch friction disc. FAW’s selection of cold-resistant spring steel ensures this critical component retains its elasticity even after an overnight soak in Siberian winter conditions.

Safety Interlocks: The Role of the Clutch Switch

Modern heavy trucks integrate mechanical control with electronic safety systems, e o Pedal de embreagem com cilindro mestre assembly is no exception. A key component here is the Conjunto do interruptor da embreagem (Parte não. 3754030-76C). This switch serves a vital safety function: it prevents the engine from cranking unless the clutch pedal is fully depressed. This interlock ensures the truck cannot accidentally lurch forward if started while in gear, a critical safety feature for mining sites where personnel may be working in close proximity to the vehicle.

The precise actuation of this switch is managed by the Rocker Arm – Clutch Switch (Parte não. 1602027-76C) e o Clutch Switch Bracket Assembly (Parte não. 1602250-76C). Dentro do Pedal de embreagem com cilindro mestre arquitetura, these components align the mechanical movement of the pedal arm with the electrical contact of the switch. Misalignment here can lead to “no-start” conditions or failure to disengage cruise control. The bracketry is designed to be rigid and vibration-resistant, maintaining this precise alignment over the vehicle’s lifespan.

Além disso, the signals generated by the Pedal de embreagem com cilindro mestre assembly interact with the engine control unit (ECU) to manage torque output during shifts. Smooth gear changes protect the transmission driveline from shock loads. A confiabilidade do Conjunto do interruptor da embreagem é fundamental; portanto, it is housed in a sealed enclosure to protect internal contacts from the condensation that inevitably forms inside the warm cabin when the outside temperature is well below freezing, ensuring consistent electrical continuity for the Pedal de embreagem com cilindro mestre sistema.

Installation Integrity: Fasteners and Maintenance

A integridade estrutural do Pedal de embreagem com cilindro mestre relies on a specific set of high-tensile fasteners. The assembly is anchored to the firewall using the Hexagon Head Bolt with Slot (Parte não. CQ1740635) e Parafuso de combinação (Parte não. CQ1460620). These are not standard hardware; they are rated to withstand the shear forces generated when a driver applies full force to the pedal in an emergency. O uso de um Porca de travamento de flange hexagonal (Parte não. CQ32608) distributes clamping load and prevents loosening due to the high-frequency vibration of the diesel engine.

A manutenção adequada do Pedal de embreagem com cilindro mestre involves regular inspection of the securement points. Mechanics must check the Anel de retenção aberto (Parte não. Q436150) that secures the pedal shaft. If this ring fails, the pedal shaft could migrate, leading to catastrophic loss of clutch control. Adicionalmente, o Pino de cabeça plana (Parte não. Q5100825) e Contrapino (Parte não. Q5002016) used in the linkage must be inspected for corrosion or fatigue, as these small parts are the linchpins of the mechanical connection in the Pedal de embreagem com cilindro mestre sistema.

Finalmente, o Pedal de embreagem com cilindro mestre assembly includes various washers like the Lavadora de mola leve (Parte não. Q40406) e Arruela Grande (Parte não. Q40206). These seemingly minor components play a major role in preventing fastener back-off and protecting the painted surfaces of the bracket from corrosion. By using genuine FAW replacement parts for even these small items, fleet managers ensure that the Pedal de embreagem com cilindro mestre remains a cohesive, reliable unit capable of enduring the grueling conditions of the Russian heavy transport sector.

Conclusão: The Pinnacle of Drivetrain Control

O Pedal de embreagem com cilindro mestre represents a critical fusion of hydraulic power and mechanical precision. Cada componente, from the cold-resistant seals in the Conjunto do cilindro mestre da embreagem to the ergonomic design of the Conjunto do pedal da embreagem, is engineered to provide the driver with absolute confidence. In the unforgiving environment of the Russian Arctic, where equipment failure can be life-threatening, the robust design of the Pedal de embreagem com cilindro mestre stands as a testament to FAW’s commitment to safety and reliability.

Para equipes de manutenção, adhering to the detailed parts breakdown of the Pedal de embreagem com cilindro mestre is essential for minimizing downtime. Regular preventative maintenance, focusing on fluid levels, bushing wear, and fastener torque, ensures that the system performs optimally. By choosing authentic FAW parts for the Pedal de embreagem com cilindro mestre, operators secure the longevity of their fleet, ensuring that every gear shift is as smooth and reliable as the first, regardless of the temperature outside.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.