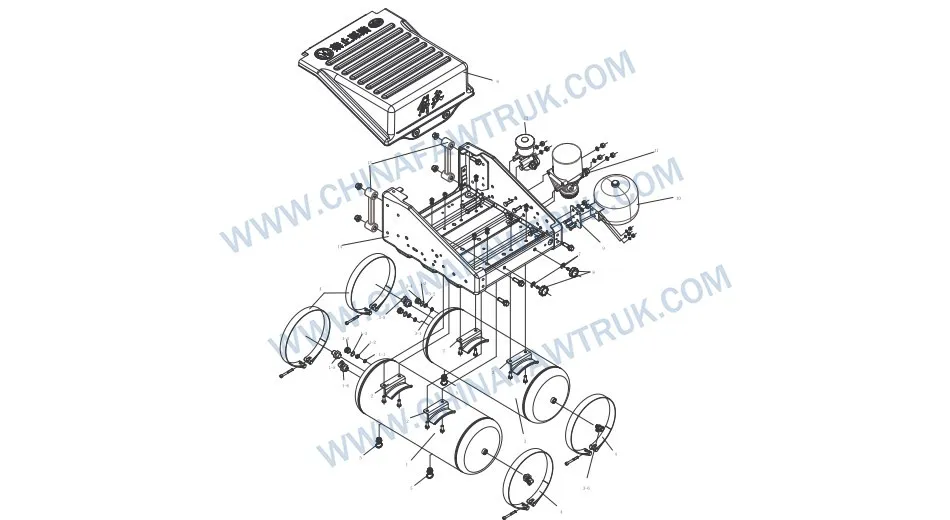

Módulo de alimentação do freio a ar: 26 Componentes Estratégicos para a Energia Pneumática Ártica Infalível

O Módulo de alimentação do freio a ar é o sistema respiratório crítico da LFM

Caminhão basculante CA3250P66K24L1TE5Z, configurado especificamente para os punitivos ambientes abaixo de zero da Federação Russa. Este conjunto não armazena apenas ar comprimido; o Módulo de alimentação do freio a ar condiciona ativamente, seca, e distribui energia pneumática para os sistemas de freio e suspensão. Garantir a integridade do Módulo de alimentação do freio a ar é fundamental para evitar o congelamento da linha e garantir o controle total do veículo em temperaturas que chegam a -50°C.

Módulo de alimentação do freio a ar

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 3513045-55R | Conjunto de reservatório de ar de câmara dupla | 1 |

| 2 | 3513081-91C | Suporte do reservatório de ar | 4 |

| 3 | 3513075-1066 | Conjunto de reservatório de ar | 1 |

| 4 | 3513095-91C | Conjunto de alça | 4 |

| 5 | 3513100-240 | Conjunto de válvula de drenagem | 3 |

| 6 | 3513801-91C | Placa de cobertura da bateria | 1 |

| 7 | 3513839-91C | Anel de retenção aberto | 2 |

| 8 | 3513837-2000 | Parafuso de travamento | 2 |

| 9 | 3513109-55R | Suporte do reservatório de regeneração | 1 |

| 10 | 3513300-79B | Conjunto de reservatório de ar de regeneração | 1 |

| 11 | 3511010-55R | Secador de ar com silenciador e conjunto de junta de tubo | 1 |

| 12 | 3529010-55R | Bomba anticongelante com conjunto de junta de tubo | 1 |

| 13 | 3513826-2001 | Suporte da Unidade de Fornecimento de Ar | 2 |

| 14 | 3513800-55R | Conjunto de reservatório de ar e suporte de bateria | 1 |

| 1-1 | 3513403-50A | Anel de vedação perfilado (Φ15.6) | 1 |

| 1-2 | 3513407-50A | Anel de encaixe (Φ12) | 1 |

| 1-3 | 3513408-50A | Anel de vedação (Φ18.5) | 1 |

| 1-4 | 3513406-50A | Manga rosqueada (M22) | 1 |

| 1-5 | T833 | Cabeça de teste de conector de plugue rápido | 1 |

| 1-6 | 3506204-55R | Conector de cotovelo | 2 |

| 3-1 | 3513403-50A | Anel de vedação perfilado (Φ15.6) | 2 |

| 3-2 | 3513407-50A | Anel de encaixe (Φ12) | 2 |

| 3-3 | 3513408-50A | Anel de vedação (Φ18.5) | 2 |

| 3-4 | 3513406-50A | Manga rosqueada (M22) | 2 |

| 3-5 | 3506204-55R | Conector de cotovelo | 1 |

| 3-6 | T833 | Cabeça de teste de conector de plugue rápido | 1 |

Resiliência Pneumática no Norte Congelado

O Módulo de alimentação do freio a ar para o FAW J6P foi projetado para enfrentar a ameaça mais perigosa às operações de caminhões na Sibéria: congelamento de umidade nas companhias aéreas. A -40ºC, mesmo pequenas quantidades de vapor de água podem se transformar em bloqueios de gelo, desativando instantaneamente o sistema de freio. Este módulo é construído em torno de uma filosofia de condicionamento centralizado, onde o Secador de ar com silenciador e conjunto de junta de tubo (Parte não. 3511010-55R) serve como a principal linha de defesa dentro do Módulo de alimentação do freio a ar arquitetura. Este secador de especificação russa apresenta um elemento de aquecimento de alta potência e um cartucho dessecante aprimorado projetado para remover agressivamente a umidade da saída do compressor antes que ela alcance os reservatórios.

Complementando o secador no Módulo de alimentação do freio a ar é o Bomba anticongelante com conjunto de junta de tubo (Parte não. 3529010-55R). Este sistema auxiliar, crucial para o “55R” designação de clima frio, injeta uma quantidade medida de anticongelante à base de álcool no fluxo de ar. Este vapor se mistura com qualquer umidade restante, reduzindo significativamente seu ponto de congelamento. Essa redundância garante que o Módulo de alimentação do freio a ar mantém um fluxo desobstruído de energia para as câmaras de freio, mesmo que o secador primário fique sobrecarregado por rápidas mudanças de temperatura durante uma mudança em um poço de mina úmido.

A lógica de montagem do Módulo de alimentação do freio a ar também reflete as prioridades do tempo frio. O Suporte da Unidade de Fornecimento de Ar (Parte não. 3513826-2001) isola os componentes de condicionamento da torção do chassi, mantendo-os próximos do calor residual do motor. Ao agrupar os componentes do tratamento dentro do Módulo de alimentação do freio a ar, FAW minimiza o comprimento da tubulação exposta entre o compressor e o secador, reduzindo a janela de oportunidade para que ocorra congelamento instantâneo antes que o ar seja tratado.

Capacidade de armazenamento e integridade estrutural

Capacidade de armazenamento dentro do Módulo de alimentação do freio a ar é gerenciado pela enorme Conjunto de reservatório de ar de câmara dupla (Parte não. 3513045-55R) e o complemento Conjunto de reservatório de ar (Parte não. 3513075-1066). Esses tanques são construídos em aço de alta resistência para suportar pressões internas superiores a 12 barra enquanto resiste ao impacto externo de detritos rochosos. O revestimento interno desses reservatórios no Módulo de alimentação do freio a ar é um epóxi especializado resistente aos efeitos corrosivos do anticongelante de álcool, garantindo integridade estrutural a longo prazo.

A segurança desses tanques pesados é crítica em estradas difíceis. O Módulo de alimentação do freio a ar utiliza robusto Suporte do reservatório de ar unidades (Parte não. 3513081-91C) combinado com o Conjunto de alça (Parte não. 3513095-91C). Essas tiras são revestidas com borracha amortecedora de vibrações para evitar atrito contra o corpo do tanque. Um tanque solto no Módulo de alimentação do freio a ar pode cortar suas linhas de conexão, levando à falha total do freio. Portanto, o Parafuso de travamento (Parte não. 3513837-2000) usado aqui apresenta um projeto de torque predominante para resistir ao afrouxamento sob vibração constante do chassi.

Um componente muitas vezes esquecido, mas vital, do Módulo de alimentação do freio a ar é o Conjunto de reservatório de ar de regeneração (Parte não. 3513300-79B), montado sozinho Suporte do reservatório de regeneração (Parte não. 3513109-55R). Este tanque dedicado armazena limpo, ar seco especificamente para fins de retrolavagem do dessecante do secador de ar. Este ciclo de autolimpeza é essencial para manter a eficiência do Módulo de alimentação do freio a ar durante longos intervalos de serviço, garantindo que o dessecante não fique saturado e inútil no meio de uma operação de inverno.

Acesso para manutenção e gerenciamento de água

Manutenção diária do Módulo de alimentação do freio a ar é simplificado através da inclusão do Conjunto de válvula de drenagem (Parte não. 3513100-240) em cada tanque. Apesar dos avançados sistemas de secagem, alguma condensação é inevitável. Estas válvulas manuais permitem que os operadores purguem água líquida e contaminantes de óleo do fundo dos reservatórios. No Módulo de alimentação do freio a ar projeto, essas válvulas são posicionadas para fácil acesso, incentivando os motoristas a realizar esta verificação essencial antes de cada turno, evitando o acúmulo de gelo no fundo do tanque.

O Módulo de alimentação do freio a ar também se integra ao armazenamento elétrico do veículo através do Conjunto de reservatório de ar e suporte de bateria (Parte não. 3513800-55R). Esta estrutura combinada economiza espaço no chassi e fornece um ponto de montagem seguro para o Placa de cobertura da bateria (Parte não. 3513801-91C). A proteção das baterias é relevante para o Módulo de alimentação do freio a ar porque o elemento de aquecimento do secador de ar e a bomba anticongelante são acionados eletricamente. Uma falha na proteção da bateria pode levar à perda de energia desses elementos de aquecimento, comprometendo a proteção contra congelamento de todo o sistema pneumático.

A capacidade de diagnóstico está incorporada diretamente no Módulo de alimentação do freio a ar através do Cabeça de teste de conector de plugue rápido (Parte não. T833). Esses pontos de teste permitem que os mecânicos conectem manômetros e verifiquem instantaneamente a pressão do sistema sem desconectar linhas ou introduzir vazamentos. Esse recurso reduz significativamente o tempo de solução de problemas para o Módulo de alimentação do freio a ar, permitindo que os técnicos isolem rapidamente problemas entre o compressor, a secadora, e os reservatórios, garantindo que o caminhão passe menos tempo na oficina e mais tempo transportando cargas.

Tecnologia de Vedação e Segurança de Conexão

A confiabilidade do Módulo de alimentação do freio a ar é em última análise definido por suas conexões. A montagem usa um padrão “50A” sistema de vedação, evidente em partes como o Anel de vedação perfilado (Parte não. 3513403-50A) e Anel de vedação (Parte não. 3513408-50A). Estes não são O-rings genéricos; eles são projetados com uma seção transversal específica para resistir à extrusão sob alta pressão e manter a elasticidade em frio extremo. Uma falha de um único anel no Módulo de alimentação do freio a ar leva a vazamentos de ar que forçam o compressor a funcionar continuamente, encurtando sua vida.

A segurança dessas conexões envolve a Manga rosqueada (Parte não. 3513406-50A) e o Anel de encaixe (Parte não. 3513407-50A). A luva roscada fornece a força axial necessária para comprimir a vedação, enquanto o anel elástico atua como uma trava secundária, evitando que a conexão vibre solta. No Módulo de alimentação do freio a ar, a especificação de torque para essas luvas é crítica. O torque insuficiente leva a vazamentos; torque excessivo pode quebrar o Conector de cotovelo (Parte não. 3506204-55R), necessitando de substituições dispendiosas.

O uso do Anel de retenção aberto (Parte não. 3513839-91C) no suporte ilustra ainda mais a atenção aos detalhes no Módulo de alimentação do freio a ar. Esses anéis garantem que os pinos de articulação e os parafusos de montagem permaneçam presos mesmo se a porca primária se soltar. Ao manter a integridade de cada fixador e vedação dentro do Módulo de alimentação do freio a ar usando apenas peças genuínas FAW, operadores garantem um ambiente livre de vazamentos, eficiente, e sistema pneumático seguro capaz de vencer os desafios da fronteira ártica.

Conclusão: O Coração da Segurança Pneumática

O Módulo de alimentação do freio a ar é a base sobre a qual a segurança do caminhão basculante FAW J6P é construída. Ele transforma cru, ar comprimido úmido em um ambiente limpo, seco, e fonte de energia confiável para o sistema de frenagem. Cada componente, da alta capacidade Conjunto de reservatório de ar de câmara dupla para o preciso Bomba anticongelante com conjunto de junta de tubo, trabalha em conjunto para derrotar os elementos. Negligenciar a manutenção do Módulo de alimentação do freio a ar convida linhas congeladas e falha de freio, riscos que são inaceitáveis na indústria pesada.

Para gerentes de frota, o Módulo de alimentação do freio a ar lista de peças serve como um roteiro para cuidados preventivos. Substituição regular do cartucho do secador, reabastecimento do reservatório de anticongelante, e a inspeção das cintas do tanque garantem a longevidade do sistema. Ao investir em peças de reposição genuínas para o Módulo de alimentação do freio a ar, operadores protegem seus motoristas e seus ativos, garantindo que seus caminhões permaneçam operacionais, independentemente de quão baixo o mercúrio cai no termômetro.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.