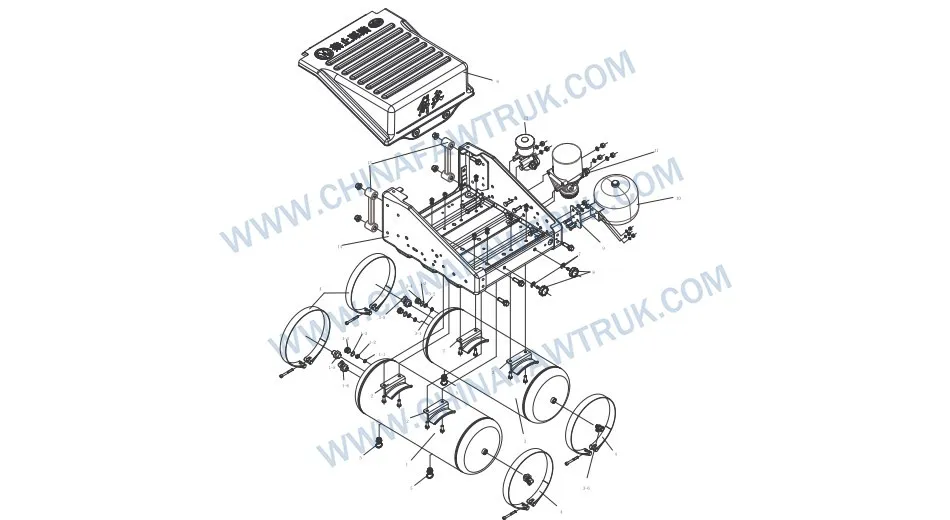

Módulo de fuente de alimentación del freno de aire: 26 Componentes estratégicos para una energía neumática inagotable en el Ártico

El Módulo de fuente de alimentación del freno de aire is the critical respiratory system of the FAW

CA3250P66K24L1TE5Z dump truck, specifically configured for the punishing sub-zero environments of the Russian Federation. This assembly does not merely store compressed air; el Módulo de fuente de alimentación del freno de aire actively conditions, se seca, and distributes pneumatic energy to the braking and suspension systems. Ensuring the integrity of the Módulo de fuente de alimentación del freno de aire is paramount for preventing line freeze-up and ensuring total vehicle control in temperatures reaching -50°C.

Módulo de fuente de alimentación del freno de aire

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 3513045-55R | Conjunto de depósito de aire de doble cámara | 1 |

| 2 | 3513081-91W. | Air Reservoir Bracket | 4 |

| 3 | 3513075-1066 | Air Reservoir Assembly | 1 |

| 4 | 3513095-91W. | Strap Assembly | 4 |

| 5 | 3513100-240 | Conjunto de válvula de drenaje | 3 |

| 6 | 3513801-91W. | Battery Cover Plate | 1 |

| 7 | 3513839-91W. | Anillo de retención abierto | 2 |

| 8 | 3513837-2000 | Perno de bloqueo | 2 |

| 9 | 3513109-55R | Regeneration Reservoir Bracket | 1 |

| 10 | 3513300-79B | Regeneration Air Reservoir Assembly | 1 |

| 11 | 3511010-55R | Air Dryer with Silencer and Pipe Joint Assembly | 1 |

| 12 | 3529010-55R | Antifreeze Pump with Pipe Joint Assembly | 1 |

| 13 | 3513826-2001 | Air Supply Unit Bracket | 2 |

| 14 | 3513800-55R | Air Reservoir and Battery Bracket Assembly | 1 |

| 1-1 | 3513403-50A | Profiled Sealing Ring (Φ15.6) | 1 |

| 1-2 | 3513407-50A | Anillo (Φ12) | 1 |

| 1-3 | 3513408-50A | Anillo de sellado (Φ18.5) | 1 |

| 1-4 | 3513406-50A | Manga roscada (M22) | 1 |

| 1-5 | T833 | Quick Plug Connector Test Head | 1 |

| 1-6 | 3506204-55R | Conector acodado | 2 |

| 3-1 | 3513403-50A | Profiled Sealing Ring (Φ15.6) | 2 |

| 3-2 | 3513407-50A | Anillo (Φ12) | 2 |

| 3-3 | 3513408-50A | Anillo de sellado (Φ18.5) | 2 |

| 3-4 | 3513406-50A | Manga roscada (M22) | 2 |

| 3-5 | 3506204-55R | Conector acodado | 1 |

| 3-6 | T833 | Quick Plug Connector Test Head | 1 |

Pneumatic Resilience in the Frozen North

El Módulo de fuente de alimentación del freno de aire for the FAW J6P is engineered to address the singular most dangerous threat to truck operations in Siberia: moisture freezing within the airlines. A -40°C, even trace amounts of water vapor can turn into ice blockages, instantly disabling the braking system. This module is built around a centralized conditioning philosophy, donde el Air Dryer with Silencer and Pipe Joint Assembly (Número de pieza. 3511010-55R) serves as the primary line of defense within the Módulo de fuente de alimentación del freno de aire arquitectura. This Russian-spec dryer features a high-wattage heating element and an enhanced desiccant cartridge designed to aggressively strip moisture from the compressor’s output before it can reach the reservoirs.

Complementing the dryer in the Módulo de fuente de alimentación del freno de aire es el Antifreeze Pump with Pipe Joint Assembly (Número de pieza. 3529010-55R). This auxiliary system, crucial for the “55R” cold-weather designation, injects a measured amount of alcohol-based antifreeze into the air stream. This vapor mixes with any remaining moisture, lowering its freezing point significantly. This redundancy ensures that the Módulo de fuente de alimentación del freno de aire maintains an unobstructed flow of energy to the brake chambers even if the primary dryer is overwhelmed by rapid temperature changes during a shift in a humid mine shaft.

The mounting logic of the Módulo de fuente de alimentación del freno de aire also reflects cold-weather priorities. El Air Supply Unit Bracket (Número de pieza. 3513826-2001) isolates the conditioning components from chassis twisting while keeping them close to the engine’s residual heat. By clustering the treatment components within the Módulo de fuente de alimentación del freno de aire, FAW minimizes the length of exposed piping between the compressor and the dryer, reducing the window of opportunity for flash freezing to occur before the air is treated.

Storage Capacity and Structural Integrity

Storage capacity within the Módulo de fuente de alimentación del freno de aire is managed by the massive Conjunto de depósito de aire de doble cámara (Número de pieza. 3513045-55R) and the supplementary Air Reservoir Assembly (Número de pieza. 3513075-1066). These tanks are constructed from heavy-gauge steel to withstand internal pressures exceeding 12 bar while resisting external impact from rock debris. The internal coating of these reservoirs in the Módulo de fuente de alimentación del freno de aire is a specialized epoxy resistant to the corrosive effects of the alcohol antifreeze, ensuring long-term structural integrity.

Securement of these heavy tanks is critical on rough haul roads. El Módulo de fuente de alimentación del freno de aire utilizes robust Air Reservoir Bracket unidades (Número de pieza. 3513081-91W.) combined with the Strap Assembly (Número de pieza. 3513095-91W.). These straps are lined with vibration-dampening rubber to prevent chafing against the tank body. A loose tank in the Módulo de fuente de alimentación del freno de aire can shear its connecting lines, leading to total brake failure. Por lo tanto, el Perno de bloqueo (Número de pieza. 3513837-2000) used here features a prevailing torque design to resist loosening under constant chassis vibration.

An often-overlooked but vital component of the Módulo de fuente de alimentación del freno de aire es el Regeneration Air Reservoir Assembly (Número de pieza. 3513300-79B), mounted on its own Regeneration Reservoir Bracket (Número de pieza. 3513109-55R). This dedicated tank stores clean, dry air specifically for the purpose of back-flushing the air dryer desiccant. This self-cleaning cycle is essential for maintaining the efficiency of the Módulo de fuente de alimentación del freno de aire over long service intervals, ensuring that the desiccant does not become saturated and useless in the middle of a winter operation.

Maintenance Access and Water Management

Daily maintenance of the Módulo de fuente de alimentación del freno de aire is simplified through the inclusion of the Conjunto de válvula de drenaje (Número de pieza. 3513100-240) on each tank. Despite the advanced drying systems, some condensation is inevitable. These manual valves allow operators to purge liquid water and oil contaminants from the bottom of the reservoirs. En el Módulo de fuente de alimentación del freno de aire diseño, these valves are positioned for easy reach, encouraging drivers to perform this essential check before every shift, preventing ice accumulation at the tank bottom.

El Módulo de fuente de alimentación del freno de aire also integrates with the vehicle’s electrical storage via the Air Reservoir and Battery Bracket Assembly (Número de pieza. 3513800-55R). This combined structure saves chassis space and provides a secure mounting point for the Battery Cover Plate (Número de pieza. 3513801-91W.). Protecting the batteries is relevant to the Módulo de fuente de alimentación del freno de aire because the air dryer’s heating element and the antifreeze pump are electrically driven. A failure in the battery protection can lead to a loss of power to these heating elements, compromising the freeze protection of the entire pneumatic system.

Diagnostic capability is built directly into the Módulo de fuente de alimentación del freno de aire a través del Quick Plug Connector Test Head (Número de pieza. T833). These test points allow mechanics to attach pressure gauges and instantly verify system pressure without disconnecting lines or introducing leaks. This feature significantly reduces troubleshooting time for the Módulo de fuente de alimentación del freno de aire, allowing technicians to quickly isolate issues between the compressor, the dryer, and the reservoirs, ensuring the truck spends less time in the shop and more time hauling loads.

Sealing Technology and Connection Security

La confiabilidad del Módulo de fuente de alimentación del freno de aire is ultimately defined by its connections. The assembly uses a standardized “50A” sealing system, evident in parts like the Profiled Sealing Ring (Número de pieza. 3513403-50A) y Anillo de sellado (Número de pieza. 3513408-50A). These are not generic O-rings; they are engineered with a specific cross-section to resist extrusion under high pressure and maintain elasticity in extreme cold. A failure of a single ring in the Módulo de fuente de alimentación del freno de aire leads to air leaks that force the compressor to run continuously, shortening its life.

Securement of these connections involves the Manga roscada (Número de pieza. 3513406-50A) y el Anillo (Número de pieza. 3513407-50A). The threaded sleeve provides the axial force necessary to compress the seal, while the snap ring acts as a secondary lock, preventing the fitting from vibrating loose. En el Módulo de fuente de alimentación del freno de aire, the torque specification for these sleeves is critical. Under-torquing leads to leaks; over-torquing can crack the Conector acodado (Número de pieza. 3506204-55R), necessitating costly replacements.

The use of the Anillo de retención abierto (Número de pieza. 3513839-91W.) on the bracketry further illustrates the attention to detail in the Módulo de fuente de alimentación del freno de aire. These rings ensure that pivot pins and mounting bolts remain captured even if the primary nut loosens. By maintaining the integrity of every fastener and seal within the Módulo de fuente de alimentación del freno de aire using only genuine FAW parts, operators ensure a leak-free, eficiente, and safe pneumatic system capable of conquering the challenges of the Arctic frontier.

Conclusión: The Heart of Pneumatic Safety

El Módulo de fuente de alimentación del freno de aire is the foundation upon which the safety of the FAW J6P dump truck is built. It transforms raw, humid compressed air into a clean, seco, and reliable energy source for the braking system. Cada componente, from the high-capacity Conjunto de depósito de aire de doble cámara to the precise Antifreeze Pump with Pipe Joint Assembly, works in concert to defeat the elements. Neglecting the maintenance of the Módulo de fuente de alimentación del freno de aire invites frozen lines and brake failure, risks that are unacceptable in heavy industry.

Para los gerentes de flota, el Módulo de fuente de alimentación del freno de aire parts list serves as a roadmap for preventative care. Regular replacement of the dryer cartridge, refilling of the antifreeze reservoir, and inspection of the tank straps ensure the system’s longevity. By investing in genuine replacement parts for the Módulo de fuente de alimentación del freno de aire, operators protect their drivers and their assets, ensuring that their trucks remain operational regardless of how low the mercury drops on the thermometer.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.