Pedal de freio com conjunto de válvula de freio: Engenharia 37 Componentes estratégicos para um controle impecável do Ártico russo

O Pedal de freio com válvula de freio assembly is the definitive command interface for the FAW CA3250P66K24L1TE5Z dump truck, engineered specifically to dominate the harsh conditions of the Russian Arctic. Unlike standard control units, this ruggedized Pedal de freio com válvula de freio module integrates pneumatic braking precision with hydraulic clutch actuation into a single, frost-resistant architecture. Mastering the intricacies of the Pedal de freio com válvula de freio is essential for fleet operators who demand instant deceleration and seamless gear shifts in temperatures plummeting to -50°C.

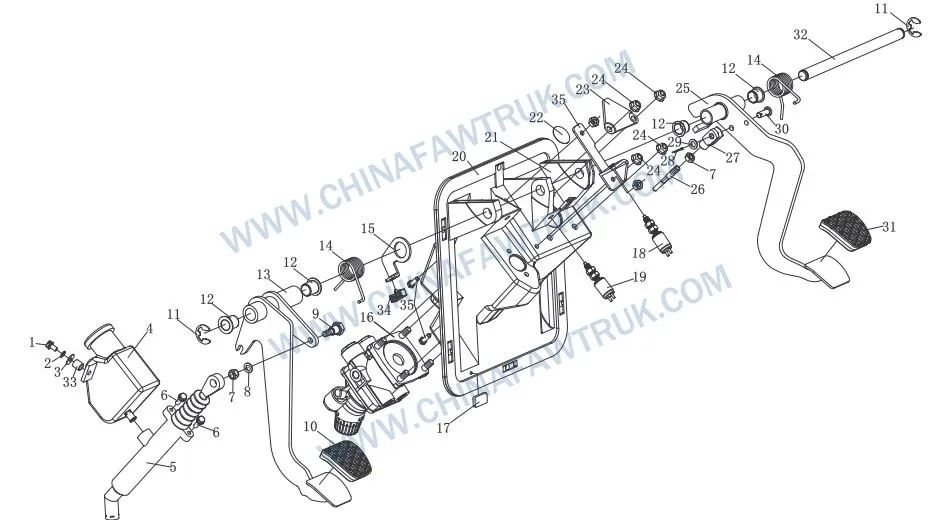

Pedal de freio com válvula de freio

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | CQ1740635 | Hexagon Head Bolt with Slot | 1 |

| 2 | Q40406 | Lavadora de mola leve | 1 |

| 3 | Q40206 | Arruela Grande | 1 |

| 4 | 1602100-50A | Oil Reservoir Assembly | 1 |

| 5 | 1602110-76C | Conjunto do cilindro mestre da embreagem | 1 |

| 6 | CQ1460620 | Parafuso de combinação | 2 |

| 7 | CQ34008 | Noz hexágono | 1 |

| 8 | Q40308 | Arruela elástica | 1 |

| 9 | 1602091-50A | Haste – Cilindro mestre | 1 |

| 10 | 1602037-50A | Bucha de pedal | 1 |

| 11 | Q436150 | Anel de retenção aberto | 2 |

| 12 | 3504061-50A | Casquilho – Brake Pedal Shaft | 4 |

| 13 | 1602020-76C | Conjunto do pedal da embreagem | 1 |

| 14 | 3504036-50A | Spring de retorno – Pedal de freio | 2 |

| 15 | 1602027-76C | Rocker Arm – Clutch Switch | 1 |

| 16 | 3514010-50A | Brake Valve and Pipe Joint Assembly | 1 |

| 17 | 1602092-50A | Pedal Limit Block | 1 |

| 18 | 3754030-76C | Conjunto do interruptor da embreagem | 1 |

| 19 | 3720010-A01 | Stop Lamp Switch Assembly | 1 |

| 20 | 3504033-50A | Junta – Pedal Assembly | 1 |

| 21 | 3504031-76C | Pedal Bracket | 1 |

| 22 | 3504038-50A | Almofada – Brake Pedal Arm | 1 |

| 23 | 3504037-50A | Placa – Brake Pedal Arm | 1 |

| 24 | CQ32608 | Porca de travamento de flange hexagonal | 4 |

| 25 | 3504070-50A | Brake Pedal Assembly | 1 |

| 26 | 3504063-50A | Haste | 1 |

| 27 | 3504062-50A | Threaded Fork – Pedal de freio | 1 |

| 28 | Q5002016 | Contrapino | 1 |

| 29 | Q40108 | Máquina de lavar | 1 |

| 30 | Q5100825 | Pino de cabeça plana | 1 |

| 31 | 3504074-50A | Bucha de pedal | 1 |

| 32 | 3504032-50A | Pedal Shaft | 1 |

| 33 | 1602102-76C | Manga – Clutch Oil Cup | 1 |

| 34 | 1602038-76C | Limit Block – Clutch Pedal | 1 |

| 35 | 1602250-76C | Clutch Switch Bracket Assembly | 1 |

| – | CQ1500620 | Parafuso de cabeça hexagonal | 2 |

| – | Q40306 | Arruela elástica | 2 |

Ergonomics and Structural Design: The Foundation of Control

The structural core of the Pedal de freio com válvula de freio assembly is the robust Pedal Bracket (Parte não. 3504031-76C). This component is engineered to withstand the repetitive high-force inputs typical of dump truck operations in mining and construction. In the FAW J6P Russian spec, o Pedal de freio com válvula de freio bracket is manufactured from high-tensile steel, providing a rigid mounting point for both the brake and clutch mechanisms. This rigidity ensures that pedal inputs into the Pedal de freio com válvula de freio system are translated linearly into braking force without the “esponjoso” feel caused by bracket flex.

Attached to this bracket is the Brake Pedal Assembly (Parte não. 3504070-50A), a key element of the Pedal de freio com válvula de freio unidade. The pedal arm geometry is optimized for the specific seating position of the J6P cabin, offering a mechanical advantage that allows the driver to modulate massive braking power with manageable foot pressure. Crucialmente, o Pedal de freio com válvula de freio assembly pivots on a precision-ground Pedal Shaft (Parte não. 3504032-50A), which is supported by multiple Casquilho – Brake Pedal Shaft unidades (Parte não. 3504061-50A). These bushings are made from self-lubricating composite materials designed to resist seizing even when the grease thickens in extreme Arctic cold.

O Pedal de freio com válvula de freio system also prioritizes driver feedback. O Spring de retorno – Pedal de freio (Parte não. 3504036-50A) plays a vital role in the Pedal de freio com válvula de freio função. Unlike standard springs that may become brittle and snap at -40°C, these springs undergo a specialized heat treatment and shot-peening process to enhance their fatigue life and low-temperature ductility. This ensures the pedal returns crisply to its neutral position every time, preventing brake drag and ensuring the Pedal de freio com válvula de freio effectively disengages the Stop Lamp Switch Assembly immediately upon release.

Hydraulic and Pneumatic Integration: Dual-System Logic

What distinguishes the Pedal de freio com válvula de freio assembly is its seamless integration of two distinct fluid systems. On the pneumatic side, o Brake Valve and Pipe Joint Assembly (Parte não. 3514010-50A) acts as the command center for the entire Pedal de freio com válvula de freio operação. When the driver depresses the pedal, o Haste (Parte não. 3504063-50A) actuates this valve, metering compressed air from the reservoirs to the relay valves. The internal seals of this brake valve are specifically formulated “50A” compounds, making the Pedal de freio com válvula de freio resistant to the hardening effects of freezing air and oil contaminants.

Simultaneamente, the bracket of the Pedal de freio com válvula de freio houses the hydraulic clutch actuation system, centrado em torno do Conjunto do cilindro mestre da embreagem (Parte não. 1602110-76C). This cylinder converts mechanical pedal force into hydraulic pressure to disengage the clutch. It is fed by the Oil Reservoir Assembly (Parte não. 1602100-50A), which is mounted high on the Pedal de freio com válvula de freio bracket to ensure gravity feeding. The reservoir is made from a translucent, impact-resistant polymer that allows for quick visual fluid level checks without opening the cap, reducing the risk of introducing moisture into the hygroscopic brake fluid—a critical maintenance advantage for the Pedal de freio com válvula de freio in snowy environments.

The mechanical connection between the pedal and the valve is fine-tuned via the Threaded Fork – Pedal de freio (Parte não. 3504062-50A), an adjustable component of the Pedal de freio com válvula de freio ligação. This adjustable linkage allows mechanics to set the precise pedal free-play. Incorrect free-play in the Pedal de freio com válvula de freio system can lead to two dangerous scenarios: excessive travel causing delayed braking, or zero play causing the brakes to bind. The threaded fork is secured with a Contrapino (Parte não. Q5002016) e Pino de cabeça plana (Parte não. Q5100825), simple yet fail-safe fasteners that prevent vibration from altering the critical calibration of the Pedal de freio com válvula de freio.

Electrical Signaling and Safety Interlocks

Beyond mechanical control, o Pedal de freio com válvula de freio assembly serves as a digital signal generator for the truck’s ECU and lighting systems. O Stop Lamp Switch Assembly (Parte não. 3720010-A01) is mechanically linked to the brake pedal arm within the Pedal de freio com válvula de freio unidade. As soon as the pedal moves, this switch completes the circuit to illuminate the rear brake lights, alerting following traffic. In the CA3250 dump truck, this signal also disengages the cruise control and exhaust brake, provando que o Pedal de freio com válvula de freio is deeply integrated into the vehicle’s logic.

De forma similar, the clutch pedal adjacent to the Pedal de freio com válvula de freio features the Conjunto do interruptor da embreagem (Parte não. 3754030-76C), mounted on the Clutch Switch Bracket Assembly (Parte não. 1602250-76C). This switch prevents the engine from starting unless the clutch is fully depressed, a safety interlock that prevents the truck from lurching forward if started in gear. The actuation of these switches relies on the precise movement of the Rocker Arm – Clutch Switch (Parte não. 1602027-76C), which must be kept free of ice and mud buildup to function correctly alongside the Pedal de freio com válvula de freio.

The reliability of these electrical components within the Pedal de freio com válvula de freio assembly is ensured by their IP67-rated enclosures, protecting internal contacts from the condensation that forms in the cab when the heater battles the Siberian cold. Inspeção regular do Conjunto do pedal da embreagem (Parte não. 1602020-76C) involves checking these switches for continuity and ensuring the wiring harnesses are securely routed away from the moving pedal arms of the Pedal de freio com válvula de freio to prevent chafing and short circuits.

Maintenance Protocols and Fastener Security

A integridade do Pedal de freio com válvula de freio assembly relies heavily on its mounting hardware. The bracket is secured to the cab firewall using high-strength fasteners like the Parafuso de cabeça hexagonal (Parte não. CQ1500620) e Porca de travamento de flange hexagonal (Parte não. CQ32608). The flange nuts feature serrated faces that bite into the metal surface, resisting the high-frequency vibrations generated by the diesel engine, garantindo o Pedal de freio com válvula de freio permanece seguro. Utilizing the correct Arruela elástica (Parte não. Q40306) prevents these bolts from backing out over thousands of kilometers of rough haul roads, protecting the alignment of the Pedal de freio com válvula de freio.

Ao longo do tempo, o Bucha de pedal (Parte não. 1602037-50A) e o Pedal Limit Block (Parte não. 1602092-50A) act as wear items within the Pedal de freio com válvula de freio estrutura. The limit block cushions the pedal’s return stroke, preventing metal-on-metal impact noise. If this rubber block degrades, the pedal travel may exceed specifications, potentially damaging the internal piston of the master cylinder. Portanto, o Pedal de freio com válvula de freio maintenance schedule must include a physical inspection of these rubber isolators and immediate replacement if cracking is observed.

Finalmente, o Manga – Clutch Oil Cup (Parte não. 1602102-76C) and the associated Limit Block – Clutch Pedal (Parte não. 1602038-76C) ensure the hydraulic reservoir on the Pedal de freio com válvula de freio assembly remains stable. A loose reservoir can lead to frothing of the hydraulic fluid due to vibration, introducing air bubbles into the clutch lines. By maintaining the tight tolerances of the Pedal de freio com válvula de freio assembly using only genuine FAW parts, operators guarantee that their fleet remains operational and safe, regardless of the harsh environmental conditions encountered in the Russian North.

Conclusão: Precision in Every Component

O Pedal de freio com válvula de freio assembly is more than a simple lever; it is a sophisticated control station that demands engineering precision. From the hydraulic sealing of the Conjunto do cilindro mestre da embreagem to the mechanical feedback of the Brake Pedal Assembly, cada um dos 37 components plays a critical role in vehicle safety. FAW’s dedication to cold-weather performance is evident in the material choices and robust design of this specific Pedal de freio com válvula de freio suporte.

Para profissionais de manutenção, understanding the interplay between the Brake Valve and Pipe Joint Assembly and the electrical switches is key to rapid troubleshooting. By adhering to the breakdown provided in this guide and utilizing authentic replacement parts, fleet managers can ensure that the Pedal de freio com válvula de freio system delivers reliable, fade-free stopping power for the lifespan of the vehicle, protecting both the driver and the valuable cargo they transport with the ultimate confidence in their Pedal de freio com válvula de freio sistema.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.