FAW Russian Two-Piece Assembly: Integrating 14 Strategic HVAC Components for Precision Arctic Climate Control

The FAW Russian Two-Piece Assembly is the thermal exchange heart of the climate control system for the FAW CA3250P66K24L1TE5Z dump truck. Situated deep within the dashboard, this central module houses both the evaporator and the heater core, effectively managing the phase changes required for cabin heating and cooling. By precisely blending air temperatures through a network of robust actuators and sensors, the FAW Russian Two-Piece Assembly ensures that the operator remains comfortable and alert, providing rapid defrosting and stable cabin warmth in the extreme volatility of the Russian Arctic environment.

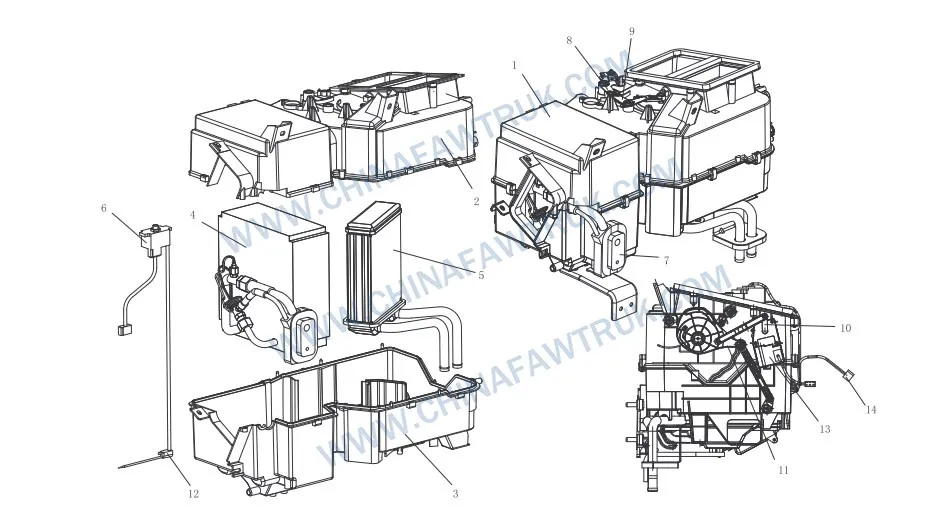

FAW Russian Two-Piece Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8101110-A65-C00 |

Two-piece Assembly (See 8100015-A65-C00) |

1 |

| 2 |

8101111-A01 |

Upper Housing – Two-piece |

1 |

| 3 |

8101112-A01 |

Lower Housing – Two-piece |

1 |

| 4 |

8107030-A65-C00 |

Evaporator Core Assembly (See 8100015-A65-C00) |

1 |

| 5 |

8101210-A65-C00 |

Heater Core Assembly (See 8100015-A65-C00) |

1 |

| 6 |

8107080-A65-C00 |

Evaporator Temperature Sensor (See 8100015-A65-C00) |

1 |

| 7 |

8106010-A65-C00 |

Expansion Valve Assembly (See 8100015-A65-C00) |

1 |

| 8 |

8101020-A65-C00 |

Temperature Actuator Rocker Arm Assembly (See 8100015-A65-C00) |

1 |

| 9 |

8101025-A65-C00 |

Mode Door Rocker Arm (See 8100015-A65-C00) |

1 |

| 10 |

8101015-A65-C00 |

Mode Door Actuator Swing Arm (See 8100015-A65-C00) |

1 |

| 11 |

8101051-A65-C00 |

Central Drive Plate (See 8100015-A65-C00) |

1 |

| 12 |

8101241-A65-C00 |

Clip – Temperature Sensor (See 8100015-A65-C00) |

1 |

| 13 |

8101010-A65-C00 |

Mode Actuator with Rocker Arm Assembly (See 8100015-A65-C00) |

1 |

| 14 |

3724295-B27 |

AC Wiring Harness Assembly |

1 |

Thermal Architecture: The Core Devices

The FAW Russian Two-Piece Assembly is defined by its two primary heat exchangers, which work in tandem to manipulate the cabin’s climate. The Evaporator Core Assembly (Part No. 8107030-A65-C00) is the cooling powerhouse. In summer, it facilitates the phase change of liquid refrigerant into gas, absorbing latent heat from the cabin air. The core features high-density aluminum fins optimized for maximum surface area, ensuring efficient heat transfer even when airflow is restricted by dust or filters. This rapid cooling capability is essential for de-fogging windows in humid conditions, a key safety feature for the FAW Russian Two-Piece Assembly system.

Conversely, the Heater Core Assembly (Part No. 8101210-A65-C00) handles the heating duties. Connected to the engine’s coolant circuit, this radiator-like component acts as a thermal battery, harvesting waste heat from the diesel engine. In the Russian Arctic, where ambient temperatures can kill, the efficiency of this core is paramount. The FAW Russian Two-Piece Assembly utilizes a heater core design with turbulators inside the tubes to promote turbulent flow, increasing heat transfer efficiency to the passing air. This ensures that warm air is available to the driver as soon as the engine reaches operating temperature.

The integration of these two “devices” (evaporator and heater) into a single module allows for the seamless blending of air. By directing airflow through either or both cores, the system can achieve any desired outlet temperature. This capability is managed by the central mixing chamber within the FAW Russian Two-Piece Assembly. The close proximity of the hot and cold cores minimizes thermal lag, providing the driver with responsive temperature control, which is critical for maintaining alertness during long, monotonous shifts in the mining pit.

Structural Integrity: Housing Logic

Encapsulating the delicate cores are the Upper Housing – Two-piece (Part No. 8101111-A01) and the Lower Housing – Two-piece (Part No. 8101112-A01). These shell components form the chassis of the FAW Russian Two-Piece Assembly. Molded from high-grade, impact-resistant polypropylene or ABS plastic, these housings are designed to withstand significant thermal shock. As the system cycles from freezing cold to scorching heat, the material must expand and contract without warping or cracking. A cracked housing would lead to air leaks, reducing system efficiency and allowing dangerous exhaust fumes or dust to bypass the filters and enter the cabin.

The mating surfaces between the upper and lower housings of the FAW Russian Two-Piece Assembly are precision-engineered to create an airtight seal. This seal is crucial for maintaining static pressure within the HVAC unit, ensuring that the blower motor’s energy is used effectively to push air through the ducts rather than leaking out behind the dashboard. Additionally, the internal geometry of the housings is sculpted to smooth airflow, reducing turbulence and the associated “whooshing” noise that can be distracting to the driver.

The Lower Housing – Two-piece also incorporates the condensate drain pan. As the Evaporator Core Assembly removes humidity from the air, water collects in this pan. The design features a sloped floor to ensure rapid drainage, preventing stagnant water from pooling. In the Russian winter, standing water can freeze, expanding and cracking the housing or blocking the drain. The engineering of the FAW Russian Two-Piece Assembly prioritizes effective moisture management to prevent these common failure modes, ensuring the longevity of the entire climate control system.

Kinematic Control: Actuators and Linkages

The precise direction and temperature of the airflow are governed by a complex system of mechanical linkages within the FAW Russian Two-Piece Assembly. Components like the Temperature Actuator Rocker Arm Assembly (Part No. 8101020-A65-C00) and the Mode Door Rocker Arm (Part No. 8101025-A65-C00) translate rotary motion from the electric actuators into linear movement of the internal blend doors. These arms are made from reinforced nylon to resist wear and fatigue. In extreme cold, plastics can become brittle; however, the material specification for these arms ensures they retain ductility, preventing them from snapping under load at -40°C.

The Central Drive Plate (Part No. 8101051-A65-C00) acts as the synchronization hub for the various air distribution flaps. It ensures that when the driver selects “Defrost,” the floor and face vents close in perfect unison while the windshield vents open. This coordination is vital for rapid de-icing. Any slop or binding in the Central Drive Plate would result in reduced airflow to the windshield, compromising safety. The FAW Russian Two-Piece Assembly utilizes low-friction cam tracks on this plate to ensure smooth, low-effort operation for the actuators.

Powering these movements are components like the Mode Actuator with Rocker Arm Assembly (Part No. 8101010-A65-C00) and the Mode Door Actuator Swing Arm (Part No. 8101015-A65-C00). These electromechanical devices must possess sufficient torque to overcome the air pressure acting on the doors and any resistance caused by frozen seals. The reliability of the FAW Russian Two-Piece Assembly depends on these actuators holding their position accurately, ensuring that the selected climate settings are maintained without drift, providing a consistent environment for the driver.

Sensors and Fluid Control

The intelligence of the system relies on feedback from the Evaporator Temperature Sensor (Part No. 8107080-A65-C00). Secured by the Clip – Temperature Sensor (Part No. 8101241-A65-C00), this probe monitors the core temperature to prevent freezing. If the evaporator gets too cold, condensation will freeze into a block of ice, stopping airflow. The sensor signals the compressor to cycle off, melting the ice. In the damp conditions of a Russian spring, this freeze-protection logic is critical for maintaining the functionality of the FAW Russian Two-Piece Assembly.

Fluid control is managed by the Expansion Valve Assembly (Part No. 8106010-A65-C00). This precision valve meters the flow of high-pressure liquid refrigerant into the evaporator. It must adapt dynamically to changes in engine speed and thermal load. A stuck expansion valve can lead to compressor failure (liquid slugging) or poor cooling performance. The FAW Russian Two-Piece Assembly utilizes a block-type valve known for its durability and resistance to clogging, ensuring reliable refrigerant metering even in the vibrating environment of a mining truck.

Finally, the AC Wiring Harness Assembly (Part No. 3724295-B27) connects all these sensors and actuators to the vehicle’s central control unit. The harness features weather-sealed connectors to prevent corrosion from the humid environment inside the dashboard. A failure in the harness would render the entire FAW Russian Two-Piece Assembly useless. By using high-grade copper conductors and robust insulation, FAW ensures that the electrical signals governing climate control are transmitted without interruption, guaranteeing the system’s responsiveness.

Conclusion: The Core of Cabin Survival

The FAW Russian Two-Piece Assembly is more than just a heater and air conditioner; it is a sophisticated thermal management module designed for survival. By integrating the Evaporator Core Assembly and Heater Core Assembly into a robust, kinematically precise housing, FAW delivers a system that can tame the wildest temperature swings of the Arctic. Every component, from the Mode Door Rocker Arm to the Expansion Valve Assembly, plays a strategic role in maintaining a habitable workspace.

For fleet maintenance, understanding the complexity of the FAW Russian Two-Piece Assembly is essential. Replacing individual components like the Temperature Actuator Rocker Arm Assembly requires precision and genuine parts to ensure the system remains balanced. By maintaining this assembly to factory specifications, operators ensure that their drivers remain warm, the windows remain clear, and the truck remains productive, regardless of the hostile weather conditions outside.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.