FAW Russian Fan: Driving 2 Strategic Subsystems for Unfailing Arctic Climate Control

The FAW Russian Fan assembly acts as the circulatory heart of the HVAC system within the FAW CA3250P66K24L1TE5Z dump truck. In the stagnant, freezing air of a Siberian mine, passive ventilation is impossible; active, high-pressure airflow is the only barrier against frostbite and windshield icing. This assembly combines a high-torque electric motor with a precision electronic regulator to deliver consistent air volume regardless of the voltage fluctuations typical in heavy-duty operations. By ensuring reliable air movement, the FAW Russian Fan guarantees that heat is effectively transferred from the core to the cabin, maintaining a survival-grade environment for the operator.

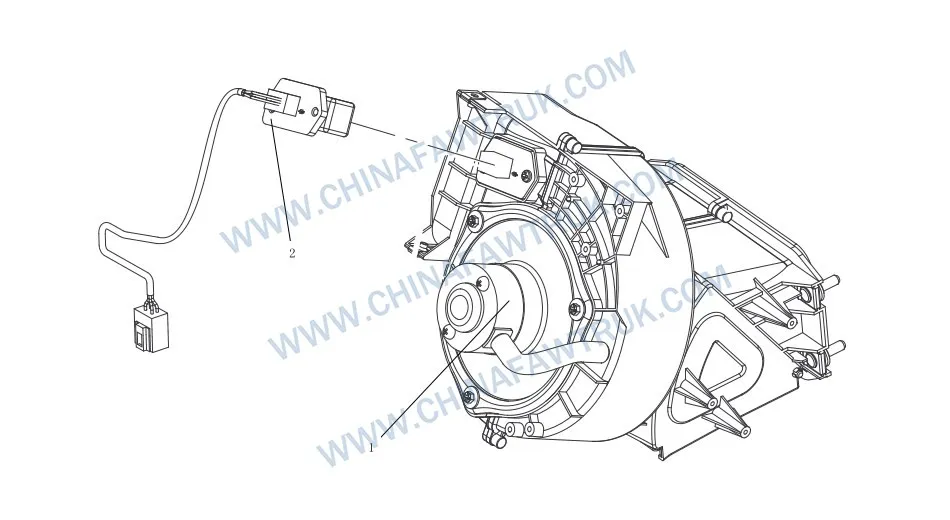

FAW Russian Fan

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8101045-A65-C00 |

Motor with Impeller Assembly (See 8100015-A65-C00) |

1 |

| 2 |

8101080-A65-C00 |

Speed Regulation Module (See 8100015-A65-C00) |

1 |

Electromechanical Power: The Motor with Impeller Assembly

The primary driver of the climate control system is the Motor with Impeller Assembly (Part No. 8101045-A65-C00). In the context of the FAW Russian Fan, this component is significantly over-engineered compared to standard road-going variants. The motor itself is a high-efficiency DC unit designed to generate substantial torque at low RPMs. This low-end torque is critical for the “cold start” scenario where the lubricant in the bearings may be thickened by the -50°C ambient temperature. A standard motor might stall or burn out trying to overcome this initial resistance, but the Motor with Impeller Assembly powers through, ensuring immediate airflow.

The impeller, which is balanced dynamically as part of the Motor with Impeller Assembly, features a centrifugal “squirrel cage” design. The blade geometry is optimized for high static pressure. In a truck cabin, the air must be forced through dense particulate filters, heater cores, and complex ducting. The FAW Russian Fan impeller is designed to maintain high air velocity against this backpressure without suffering from aerodynamic stall or excessive noise generation. The material of the impeller is a glass-fiber reinforced polymer chosen for its dimensional stability; it does not shrink or become brittle in the extreme cold, preventing catastrophic shattering at high speeds.

Furthermore, the Motor with Impeller Assembly incorporates internal shielding to protect the commutator and brushes from conductive carbon dust and moisture. In the humid environment of a heating cabin, condensation is a constant threat. The FAW Russian Fan motor housing is sealed to an IP-rated standard that prevents water ingress, which could otherwise cause short circuits or corrosion of the internal windings. This focus on internal durability ensures that the Motor with Impeller Assembly provides thousands of hours of service without requiring brush replacement or maintenance.

Intelligent Control: The Speed Regulation Module

Governing the raw power of the fan motor is the Speed Regulation Module (Part No. 8101080-A65-C00). This component, often referred to as the blower resistor or power transistor, is the brain behind the FAW Russian Fan. Unlike old-fashioned wire-wound resistors that simply wasted energy as heat to slow the fan down, this modern Speed Regulation Module utilizes Pulse Width Modulation (PWM) technology. PWM allows for infinitely variable fan speeds, enabling the automatic climate control system to make micro-adjustments to airflow, maintaining the cabin temperature with precision rather than cycling between “too hot” and “too cold.”

The Speed Regulation Module is structurally integrated into the airflow path of the FAW Russian Fan system. This positioning is deliberate; the large aluminum heatsink fins of the module must be actively cooled by the passing air. In the FAW Russian Fan application, this cooling is vital because the module handles high amperage currents. If the module were to overheat, thermal protection circuits would shut down the fan to prevent fire, leaving the driver without heat. The aerodynamic design of the module’s heatsink ensures maximum thermal transfer efficiency even at low fan speeds.

Durability of the Speed Regulation Module is paramount in the mining environment. The electronics are potted in a dense, thermally conductive epoxy resin. This potting protects the delicate circuit board components from the intense vibration of the dump truck chassis and from moisture intrusion. A failed Speed Regulation Module typically results in a fan that only works at maximum speed or not at all. By ruggedizing this component, FAW ensures that the driver retains full control over the FAW Russian Fan system, allowing for gentle defrosting or maximum blast heating as required.

Arctic Performance and De-Icing Capability

The true test of the FAW Russian Fan occurs during the initial start-up after a night parked at -40°C. At these temperatures, the windshield is often coated in a thick layer of ice. The Motor with Impeller Assembly must instantly deliver maximum air volume to the defroster ducts. Any delay or hesitation due to frozen bearings or weak magnetic fields in the motor would prolong the de-icing process, delaying the vehicle’s deployment. The FAW Russian Fan is calibrated to provide a “boost” current during these conditions, ensuring the impeller spins up to speed rapidly to clear the glass.

The interaction between the Speed Regulation Module and the vehicle’s ECU is also tuned for cold weather. The module is designed to soft-start the Motor with Impeller Assembly. A sudden spike of full current into a frozen motor could shear the impeller shaft or strip the plastic blades. The Speed Regulation Module ramps up the voltage over a few milliseconds, breaking the stiction of the cold bearings gently before applying full power. This intelligent management significantly extends the mechanical life of the FAW Russian Fan components.

Furthermore, the material selection for the connector plugs on both the Motor with Impeller Assembly and the Speed Regulation Module is critical. Standard plastics can crack when plugs are disconnected for testing in the cold. The FAW Russian Fan utilizes nylon-based connector housings that remain tough in the cold. The terminal pins are plated with high-conductivity alloys to prevent fretting corrosion—a common issue caused by thermal expansion and contraction cycles that can lead to intermittent electrical faults in the FAW Russian Fan circuit.

System Integration and Noise Control

A key performance metric for the FAW Russian Fan is acoustic comfort. In a working truck, excessive fan noise can mask engine warning sounds or radio communications. The Motor with Impeller Assembly is precision-balanced to minimize vibration transmission into the HVAC housing. The motor mounts typically use rubber isolators that decoupling the FAW Russian Fan from the hard plastic of the dashboard. This results in a “whoosh” of air rather than a mechanical hum or whine, reducing driver irritation during long shifts.

The Speed Regulation Module also plays a role in noise control. Poorly designed PWM controllers can cause the motor windings to “sing” or whine at certain frequencies. The FAW Russian Fan module operates at a frequency above the range of human hearing, ensuring silent electrical operation. This attention to detail in both the Motor with Impeller Assembly and the Speed Regulation Module reflects a holistic design approach where operator comfort is treated as a component of operational safety.

Finally, the integration of these two components ensures system redundancy. The Speed Regulation Module contains protection circuits that monitor the health of the Motor with Impeller Assembly. If the motor jams due to debris ingestion (a common risk in dirty mining environments), the module detects the over-current situation and cuts power, preventing the wiring harness from melting. This self-protection feature of the FAW Russian Fan prevents a minor mechanical jam from escalating into a major electrical fire, protecting the asset.

Conclusion: The Heart of the HVAC System

The FAW Russian Fan is a compact but critical assembly that underpins the entire climate control strategy of the CA3250 dump truck. By pairing the robust torque of the Motor with Impeller Assembly with the precision control of the Speed Regulation Module, FAW delivers a system capable of mastering the extreme atmospheric variances of the Russian Arctic. These two components work in perfect unison to ensure that air—hot or cold—is delivered exactly where the driver needs it, instantly and reliably.

For fleet maintenance teams, recognizing the interdependence of these parts is vital. A failure in the Speed Regulation Module is often a symptom of an aging Motor with Impeller Assembly drawing excessive current. Replacing them as a pair is often the best practice to ensure long-term reliability. By utilizing genuine FAW parts for the FAW Russian Fan, operators guarantee that their vehicles remain safe, comfortable, and compliant, ready to face the freezing challenges of the northern frontier.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.