FAW Russian External Air Filter: Defending Cabin Air Quality with 5 Strategic Components for Arctic Operations

The FAW Russian External Air Filter is the primary atmospheric respiratory defense for the FAW CA3250P66K24L1TE5Z dump truck. Operating in the extreme dust of open-pit mines and the blinding powder snow of the Russian Arctic, this assembly prevents contaminants from compromising the HVAC system. By filtering out abrasive silica particles and moisture before they enter the climate control unit, the FAW Russian External Air Filter ensures the longevity of the evaporator core and guarantees a safe, breathable environment for the operator in temperatures as low as -50°C.

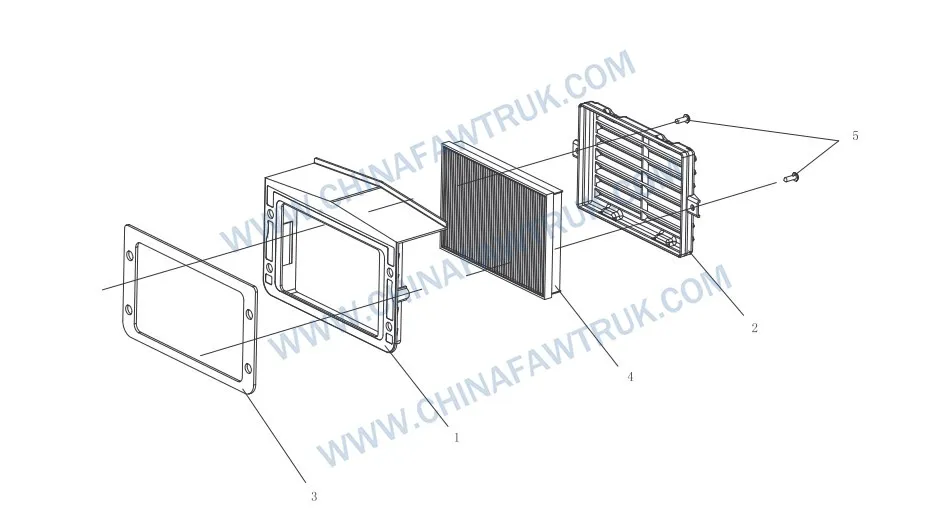

FAW Russian External Air Filter

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8101571-B27 |

Case A – External Air Filter |

1 |

| 2 |

8101572-A01 |

Case B – External Air Filter |

1 |

| 3 |

8101573-A01 |

Rubber Gasket – External Air Filter |

1 |

| 4 |

8101574-A01 |

Filter Element – External Air Filter |

1 |

| 5 |

CQ2714816 |

Cross Recessed Pan Head Tapping Screw |

2 |

Filtration Core: The Element of Protection

The functional nucleus of the FAW Russian External Air Filter is the Filter Element – External Air Filter (Part No. 8101574-A01). This is not a standard automotive paper filter; it is a high-capacity, multi-stage media engineered for the extreme dust loading found in mining operations. The fibers are electrostatically charged to attract and hold microscopic silica particles that would otherwise pass through conventional media. In the context of the CA3250 dump truck, this level of filtration is critical. If abrasive dust enters the HVAC system, it acts as a grinding compound on the blower motor bearings and clogs the delicate fins of the evaporator core, leading to rapid system failure.

The structural integrity of the Filter Element – External Air Filter is reinforced to withstand high humidity and direct snow ingestion. Standard paper filters can collapse or turn into pulp when saturated with melted snow, blocking airflow entirely. The FAW Russian External Air Filter element utilizes a synthetic blend that resists water saturation. This hydrophobic characteristic ensures that even during a heavy blizzard or when following a water truck on a haul road, the filter maintains its structural shape and porosity, allowing the FAW Russian External Air Filter to continue supplying fresh air to the cabin without suffocating the HVAC system.

Furthermore, the pleat geometry of the Filter Element – External Air Filter is optimized to maximize surface area within the compact housing. This increased surface area extends the service intervals of the FAW Russian External Air Filter, a vital consideration for fleet managers looking to minimize downtime. In the dusty environment of a coal mine, a standard filter might need daily replacement, but the high-capacity design of this element allows for longer operational periods. Regular inspection of this element is the single most important maintenance task for ensuring the driver’s respiratory health and the vehicle’s climate control efficiency.

Housing Durability and Arctic Material Science

Encasing the filter media are the structural shells: Case A – External Air Filter (Part No. 8101571-B27) and Case B – External Air Filter (Part No. 8101572-A01). These components form the first line of physical defense against the elements. The material selection for these cases is driven by the “Russian Cold Zone” requirements. They are molded from an impact-modified polypropylene that retains its ductility at temperatures as low as -50°C. Standard plastics would become brittle and shatter upon impact from flying gravel or ice chunks, but the housing of the FAW Russian External Air Filter absorbs the energy, protecting the internal element.

The design of Case A – External Air Filter incorporates an aerodynamic intake grille that functions as a pre-separator. The geometry of the louvers forces the incoming air to make sharp turns. Heavier particles like snowflakes and water droplets, carrying more momentum, cannot make these turns and are separated from the airstream before they reach the filter media. This passive inertial separation significantly reduces the load on the Filter Element – External Air Filter, preventing premature clogging during snowstorms. This design feature highlights the specialized nature of the FAW Russian External Air Filter for adverse weather conditions.

Case B – External Air Filter serves as the mounting interface to the vehicle’s plenum. It must maintain a rigid shape to ensure a proper seal against the cabin firewall. Any warping in this component due to thermal cycling (engine heat vs. arctic air) would create gaps, allowing unfiltered air to bypass the system. The engineering of the FAW Russian External Air Filter housing includes internal ribbing to prevent distortion, ensuring that the entire assembly remains dimensionally stable throughout the vehicle’s service life, regardless of the temperature fluctuations it endures.

Sealing Integrity: The Rubber Gasket Strategy

The integrity of the FAW Russian External Air Filter relies heavily on the Rubber Gasket – External Air Filter (Part No. 8101573-A01). This component seals the interface between the filter housing and the vehicle body, as well as the seal between the two halves of the case. In the Russian Arctic, seal failure is a primary cause of HVAC malfunction. If this gasket stiffens and cracks in the cold, it allows moisture to bypass the filter. This moisture then freezes on the evaporator core, blocking airflow and potentially causing the heater box to crack from ice expansion.

The material used for the Rubber Gasket – External Air Filter is a high-grade EPDM (Ethylene Propylene Diene Monomer) rubber. EPDM is chosen for its exceptional weather resistance and its ability to remain flexible at extreme sub-zero temperatures. Unlike natural rubber or standard neoprene, which can harden into a glass-like state, the EPDM gasket maintains its elasticity, conforming to the mating surfaces of Case A – External Air Filter and Case B – External Air Filter to create a hermetic seal. This ensures that 100% of the intake air passes through the filtration media.

Furthermore, the profile of the Rubber Gasket – External Air Filter is designed to resist compression set. Over time, constant pressure from the mounting screws can flatten a gasket, reducing its sealing force. The cross-section of this gasket is engineered to provide continuous back-pressure, maintaining the seal even as the plastic housing expands and contracts with thermal changes. This reliability prevents the ingestion of exhaust fumes and road dust, preserving the air quality inside the cabin and ensuring the FAW Russian External Air Filter performs its critical safety function.

Fastening and Maintenance Accessibility

Securing the assembly together are the Cross Recessed Pan Head Tapping Screw units (Part No. CQ2714816). These fasteners are critical for maintaining the compression on the Rubber Gasket – External Air Filter. The choice of a tapping screw allows for a secure bite into the polymer of the housing, creating a vibration-resistant bond. In the shaking environment of a dump truck, screws can back out; however, the coarse thread pitch of these specific screws is designed to grip the plastic of Case B – External Air Filter firmly, preventing the housing from rattling apart.

The “Cross Recessed” (Phillips) head design ensures that the FAW Russian External Air Filter can be serviced with standard tools found in any driver’s kit. Accessibility is key in the field. When a filter becomes clogged during a shift, the driver or mechanic must be able to open the housing quickly to replace or clean the Filter Element – External Air Filter. The design of the housing places these screws in accessible locations, avoiding the need to dismantle other dashboard components, thereby reducing maintenance downtime.

Additionally, the screws likely feature a corrosion-resistant coating suitable for the “Russian Cold Zone.” Standard black phosphate screws rust quickly when exposed to road salt spray, seizing in place or staining the housing. The Cross Recessed Pan Head Tapping Screw used in the FAW Russian External Air Filter assembly is treated to withstand this corrosive environment, ensuring that the housing can be opened and closed repeatedly over the life of the vehicle without the fasteners stripping or snapping.

Conclusion: The Guardian of Cabin Health

The FAW Russian External Air Filter is a deceptive simple yet structurally vital component of the CA3250 dump truck. It stands as the barrier between the clean, controlled environment of the cabin and the harsh, polluted reality of the mining pit. By integrating the high-efficiency Filter Element – External Air Filter with the robust, cold-resistant housing components like Case A – External Air Filter, FAW delivers a system that protects both the machine and the man.

For fleet operators, the maintenance of the FAW Russian External Air Filter is a direct investment in productivity. A clogged filter leads to poor heating performance, foggy windows, and driver fatigue. By ensuring that the Rubber Gasket – External Air Filter is intact and the element is replaced regularly with genuine parts, maintenance teams uphold the safety standards of the fleet. The FAW Russian External Air Filter is essential for ensuring that the truck remains a safe haven for the operator in the world’s most unforgiving climates.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.