FAW Russian Rear Axle Sensor Logic: Safeguarding 12 Precision Elements for Flawless ABS Data Integrity

The FAW Russian Rear Axle Sensor logic assembly acts as the digital nervous system for the CA3250P66K24L1TE5Z dump truck’s braking architecture. Operating in the unforgiving Siberian climate requires more than just mechanical strength; it demands precise electronic feedback. This assembly captures critical wheel speed data, enabling the Anti-Lock Braking System (ABS) to modulate pressure and prevent hazardous skids on icy gradients. Ensuring the calibration and protection of the FAW Russian Rear Axle Sensor is the single most important factor in maintaining vehicle stability control during winter operations.

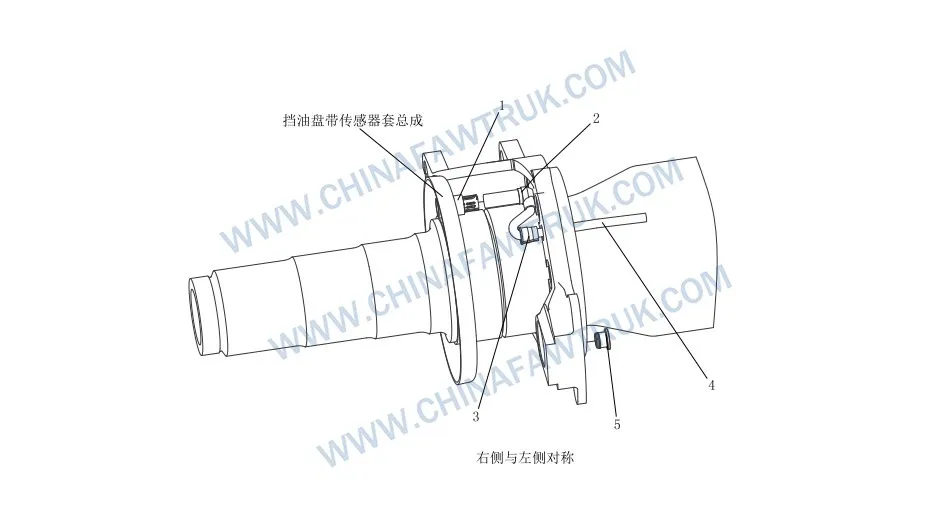

FAW Russian Rear Axle Sensor

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3550361-6S | Sensor Sleeve | 2 |

| 2 | 3550360-6S | Wheel Speed Sensor Assembly | 2 |

| 3 | 3550381BA0S | Positioning Sleeve | 4 |

| 4 | 3550351BA0S | Rubber Protective Sleeve | 2 |

| 5 | 3502861-A0B | Plug – Rear Brake Bracket | 2 |

The Core Technology: Inductive Speed Sensing

At the epicenter of the FAW Russian Rear Axle Sensor logic assembly is the Wheel Speed Sensor Assembly (Part No. 3550360-6S). This component utilizes variable reluctance technology to detect the rotational velocity of the wheel hub. As the exciter ring (tone wheel) rotates with the hub, its teeth pass through the sensor’s magnetic field, inducing an AC voltage signal. The frequency of this signal is directly proportional to wheel speed. In the context of the FAW Russian Rear Axle Sensor, the coil windings and internal magnets are encapsulated in a specialized resin. This potting process is critical for the Russian “Cold Zone” specification, as it prevents thermal shock from fracturing the internal copper windings when the sensor transitions from -50°C ambient air to the radiant heat of the brake drum.

The signal integrity of the FAW Russian Rear Axle Sensor is paramount for the functioning of the EBS (Electronic Braking System) and ABS. If the sensor signal is erratic or lost, the ECU defaults to a non-ABS mode, which can be catastrophic on icy roads. The Wheel Speed Sensor Assembly features a high-grade, shielded cable that resists electromagnetic interference (EMI) from the truck’s alternator and transmission retarder. Furthermore, the cable jacketing is formulated from cross-linked polyethylene to maintain flexibility at cryogenic temperatures, preventing the insulation from cracking and shorting out due to chassis articulation.

The FAW Russian Rear Axle Sensor assembly is designed for redundancy and reliability. The sensor head is hermetically sealed to IP69K standards, allowing it to withstand high-pressure washdowns and submersion in slush. This level of protection is essential because the rear axle sensors are constantly bombarded by road spray containing corrosive de-icing salts. By maintaining a clean, strong signal, the FAW Russian Rear Axle Sensor allows the truck’s computer to make micro-adjustments to brake pressure milliseconds before a wheel lockup occurs, preserving steering authority and preventing jackknifing.

Mounting Precision: The Critical Air Gap

The performance of the FAW Russian Rear Axle Sensor is entirely dependent on its physical positioning relative to the tone ring. This relationship is managed by the Sensor Sleeve (Part No. 3550361-6S) and the Positioning Sleeve (Part No. 3550381BA0S). These components create a friction-fit interface that holds the sensor securely while allowing for initial calibration. The air gap—the distance between the sensor tip and the tone ring tooth—must be microscopic, typically less than 0.7mm. The FAW Russian Rear Axle Sensor uses the positioning sleeve to maintain this gap dynamically.

In the heavy-duty environment of a dump truck, wheel bearings have a designated amount of play, and the axle housing flexes under load. A rigid mount would destroy the sensor immediately upon contact with the rotating ring. The Positioning Sleeve in the FAW Russian Rear Axle Sensor assembly acts as a specific clutch mechanism. It holds the sensor tight enough to prevent it from backing out due to vibration but allows it to be pushed back if the tone ring touches it due to bearing runout. This “push-out” capability is a fail-safe feature of the FAW Russian Rear Axle Sensor design, sacrificing the air gap setting rather than shearing off the sensor head.

The material composition of the Sensor Sleeve utilizes a beryllium-copper alloy or stainless steel spring material that retains its tension properties in extreme cold. Standard spring steel can lose its clamping force or become brittle in the Russian winter. By using these advanced materials, the FAW Russian Rear Axle Sensor ensures that the sensor does not vibrate loose on corrugated haul roads. A loose sensor generates a “noisy” signal that the ECU interprets as a fault, leading to false ABS activation or system shutdown.

Environmental Defense: Sealing and Protection

The location of the FAW Russian Rear Axle Sensor on the wheel end exposes it to the harshest elements imaginable: mud, rocks, ice, and intense heat. To combat this, the assembly includes the Rubber Protective Sleeve (Part No. 3550351BA0S). This boot fits over the cable exit and the sensor body, preventing water from wicking down the cable and entering the sensor housing. In the FAW Russian Rear Axle Sensor specification, this rubber is a silicone-based EPDM compound that stays flexible at -50°C, ensuring the seal is never compromised by cracking.

Furthermore, the brake bracket itself acts as a shield, but it requires sealing to prevent the ingress of conductive brake dust. The Plug – Rear Brake Bracket (Part No. 3502861-A0B) seals the access ports used for sensor installation. If this plug is missing, magnetic brake dust accumulates on the magnetic tip of the Wheel Speed Sensor Assembly. This accumulation, known as “fuzzing,” alters the magnetic field and dampens the signal voltage. The FAW Russian Rear Axle Sensor relies on these plugs to keep the sensing environment clean and accurate.

The integrity of the FAW Russian Rear Axle Sensor wiring harness is also critical. The cable routing paths are designed to avoid pinch points during suspension travel. The assembly instructions dictate specific strain relief loops to prevent the cable from being pulled tight when the axle drops to full extension. Any breach in the cable insulation allows brine to enter the copper strands, leading to “black wire corrosion” that can travel meters up the harness, destroying the FAW Russian Rear Axle Sensor connection at the chassis harness interface.

Diagnostics and Maintenance Strategy

Troubleshooting the FAW Russian Rear Axle Sensor requires an understanding of its resistance and voltage characteristics. Technicians typically measure the resistance of the Wheel Speed Sensor Assembly (usually between 1000 and 2000 ohms) to check for open circuits or shorts. However, the most definitive test for the FAW Russian Rear Axle Sensor is measuring the AC voltage output while spinning the wheel. A healthy sensor should generate a clean sine wave that increases in amplitude and frequency with wheel speed.

When replacing components, the Positioning Sleeve (Part No. 3550381BA0S) and Sensor Sleeve (Part No. 3550361-6S) must always be replaced along with the sensor. Reusing old sleeves is the leading cause of sensor migration and signal dropout. In the FAW Russian Rear Axle Sensor maintenance protocol, the sensor bore in the bracket must be thoroughly cleaned of rust and old grease before installing the new sleeves. Using a conductive anti-seize paste is strictly prohibited as it interferes with the grounding and signal purity of the FAW Russian Rear Axle Sensor.

Finally, visual inspection of the Rubber Protective Sleeve and Plug – Rear Brake Bracket should be part of every brake service. Preventing contamination is far cheaper than diagnosing intermittent ABS faults. By adhering to these protocols and using genuine parts for the FAW Russian Rear Axle Sensor, fleet operators ensure that the vehicle’s safety systems remain vigilant, protecting the driver and the asset on every trip.

Conclusion: The Data Behind the Stopping Power

The FAW Russian Rear Axle Sensor logic assembly is a small but indispensable cluster of components. While it lacks the physical mass of the brake drums or shoes, its role in managing the vehicle’s kinetic energy is equally significant. The 12 components, including the Wheel Speed Sensor Assembly and the critical Positioning Sleeve, form a cohesive unit that translates mechanical motion into digital safety data.

For fleet maintenance teams, treating the FAW Russian Rear Axle Sensor with the same respect as the mechanical friction components is essential. A truck with powerful brakes but no ABS control is a liability on ice. By investing in genuine replacement sensors and ensuring precise installation, operators guarantee that their FAW J6P trucks maintain the intelligent control necessary to navigate the hazardous conditions of the Russian heavy transport sector.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.