FAW Russian Fuel Supply System: 43 Precision Components for Unmatched Arctic Reliability

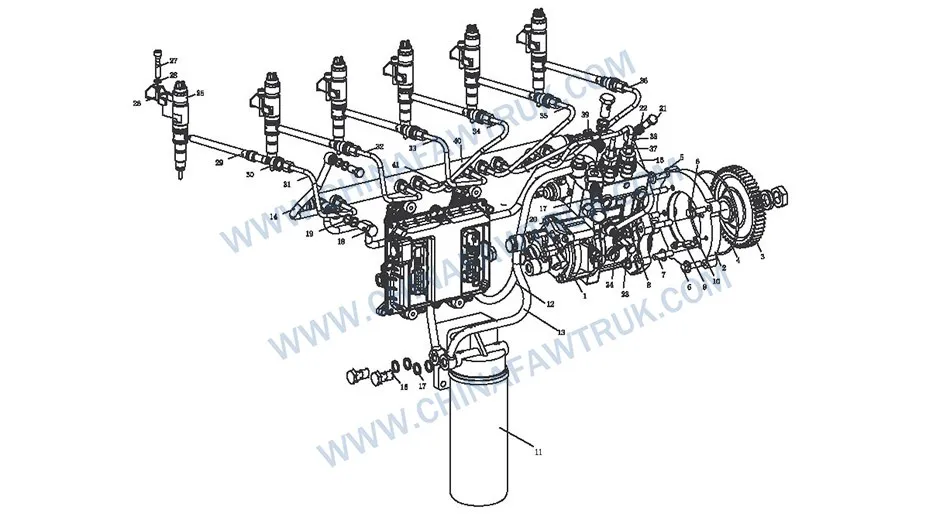

The FAW Russian Fuel Supply System is the hydrodynamic lifeline of the CA3250P66K24L1TE5Z dump truck. Engineered to deliver diesel at pressures exceeding 1800 bar, this Common Rail system ensures precise atomization even in the freezing Russian winter. This guide dissects the high-pressure pump, injectors, and intricate piping required for flawless combustion.

FAW Russian Fuel Supply System

Pressure Generation: The High-Pressure Pump Assembly

At the core of the FAW Russian Fuel Supply System is the High Pressure Oil Pump Assembly (Part No. 1111010-73D). This mechanical pump is responsible for pressurizing the fuel rail. Unlike older rotary pumps, this unit must generate consistent pressure regardless of engine speed, a capability vital for cold starts in the Russian Arctic where fuel viscosity changes dramatically.

The pump is driven by the Fuel Injection Pump Drive Gear (Part No. 1111216-81D), which meshes directly with the engine’s timing gear train. In the FAW Russian Fuel Supply System, the backlash tolerance of this gear is critical; any play would result in timing fluctuations. The gear is secured to the pump shaft, ensuring absolute synchronization with the piston stroke.

Mounting accuracy is maintained by the Locating Pin (Part No. 1111226-59D) and the High Pressure Oil Pump Connection Flange (Part No. 1111228-81D). These components ensure the pump body remains rigid against the engine block. Even microscopic movement in the FAW Russian Fuel Supply System pump mounting can lead to gear wear or high-pressure line fatigue.

Distribution Logic: The Common Rail and Piping

The accumulated pressure is stored in the High Pressure Oil Rail Assembly (Part No. 1129110-81D), often called the Common Rail. This thick-walled forged steel tube acts as an accumulator, damping the pressure pulses from the pump. In the FAW Russian Fuel Supply System, the rail must withstand internal pressures up to 1800 bar without expanding or cracking in extreme cold.

Delivering fuel to this rail are the High Pressure Oil Pipe Assembly I (Part No. 1129070-81D) and Assembly II (Part No. 1129080-81D). These pipes connect the pump to the rail. The FAW Russian Fuel Supply System utilizes seamless stainless steel tubing for these lines to resist the corrosive effects of high-sulfur diesel often found in remote logistics routes.

From the rail, fuel is distributed to individual cylinders via specific lines, such as the First Cylinder High Pressure Oil Pipe Assembly (Part No. 1129010-81D). Each pipe in the FAW Russian Fuel Supply System is bent to a precise geometry to ensure equal length and pressure drop. Vibration is controlled by the High Pressure Oil Pipe Clamp Assembly (Part No. 1129090-73D), which prevents resonant frequencies from fracturing the lines.

Precision Delivery: Injectors and Sealing

The final stage of the FAW Russian Fuel Supply System is the Fuel Injector Assembly (Part No. 1112010-51B). These electro-hydraulic units are capable of multiple injection events per combustion cycle. This multi-burst capability is vital for cold starts, pre-warming the chamber before the main ignition, a key feature for Arctic reliability.

Securing the injectors against the immense cylinder pressure requires the Injector Press Plate (Part No. 1112011-81D) and the Injector Press Plate Bolt (Part No. 1112013-81D). The FAW Russian Fuel Supply System relies on this clamping mechanism to compress the Spherical Washer (Part No. 1112014-81D) at the base of the injector, sealing the combustion chamber.

Any leak at the spherical washer allows combustion gases to blow back into the injector bore, overheating the FAW Russian Fuel Supply System components and causing carbon seizure. Therefore, replacing these washers and properly torquing the press plate bolts is a mandatory step during any top-end maintenance procedure.

Circulation and Return: Maintaining Flow

Before reaching the high-pressure pump, fuel passes through the Inlet Pipe Assembly – Transfer Pump to Fine Filter (Part No. 1104030-18C) and the Fuel Fine Filter Assembly (Part No. 1117010-81D). The FAW Russian Fuel Supply System prioritizes filtration to protect the sensitive rail and injectors.

Excess fuel is routed back to the tank via the Return Pipe Assembly (Part No. 1104050-81D). This flow carries away heat from the injectors. In the FAW Russian Fuel Supply System, fluid connections are secured with Hollow Bolts (Part Nos. 1104036-73D, 1104073-D6) and sealed with copper Sealing Washers (Part Nos. CQ72310T5, CQ72314T5).

These copper washers are essential for the FAW Russian Fuel Supply System. Unlike rubber O-rings, copper does not become brittle in extreme cold. It deforms to create a permanent metal-to-metal seal, ensuring that air does not enter the fuel lines during the cool-down phase, which would cause hard starting the next morning.

Component Breakdown List

The following table is a complete, itemized breakdown of the FAW Russian Fuel Supply System. It includes all 43 components listed in the assembly diagrams, ensuring no small washer or bolt is overlooked during maintenance.

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1111010-73D |

High Pressure Oil Pump Assembly |

1 |

| 2 |

1111228-81D |

High Pressure Oil Pump Connection Flange |

1 |

| 3 |

1111216-81D |

Fuel Injection Pump Drive Gear |

1 |

| 4 |

CQ73431550C |

Hydraulic Pneumatic O-Ring Rubber Seal |

1 |

| 5 |

Q1841030 |

Hexagon Flange Bolt (Coarse Shank/Standard) |

2 |

| 6 |

Q1841040 |

Hexagon Flange Bolt (Coarse Shank/Standard) |

2 |

| 7 |

CQ1201030 |

Double End Stud |

4 |

| 8 |

CQ39610 |

Hexagon Flange Nut |

4 |

| 9 |

1111226-59D |

Locating Pin |

1 |

| 10 |

1111227-59D |

Sleeve |

1 |

| 11 |

1117010-81D |

Fuel Fine Filter Assembly |

1 |

| 12 |

1104030A51B |

Inlet Pipe Assy – Transfer Pump to Fine Filter |

1 |

| 13 |

1104040A51B |

Inlet Pipe Assy – Fine Filter to High Pressure Pump |

1 |

| 14 |

1104050-81D |

Return Pipe Assembly |

1 |

| 15 |

1104070-81D |

Oil Inlet Pipe Assembly |

1 |

| 16 |

1104036-73D |

Hollow Bolt (Transfer Pump In/Out) |

6 |

| 17 |

CQ72316T5 |

Sealing Washer |

14 |

| 18 |

1104073-D6 |

Hollow Bolt – Oil Return Pipe |

2 |

| 19 |

CQ72314T5 |

Sealing Washer |

4 |

| 20 |

1117038-60D |

Hollow Bolt |

1 |

| 21 |

1104076-53D |

Hollow Bolt – Oil Lubrication Pipe |

1 |

| 22 |

CQ72312T5 |

Sealing Washer |

2 |

| 23 |

1104076-73D |

Hollow Bolt – Injection Pump Oil Inlet |

1 |

| 24 |

CQ72310T5 |

Sealing Washer |

2 |

| 25 |

1112010-51B |

Fuel Injector Assembly |

6 |

| 26 |

1112011-81D |

Injector Press Plate |

6 |

| 27 |

1112013-81D |

Injector Press Plate Bolt |

6 |

| 28 |

1112014-81D |

Spherical Washer |

6 |

| 29 |

1112030-81D |

High Pressure Pipe Connector Assy |

6 |

| 30 |

1112031-29D |

Intermediate Nut – High Pressure Pipe |

6 |

| 31 |

1129010-81D |

1st Cylinder High Pressure Pipe Assy |

1 |

| 32 |

1129020-81D |

2nd Cylinder High Pressure Pipe Assy |

1 |

| 33 |

1129030-81D |

3rd Cylinder High Pressure Pipe Assy |

1 |

| 34 |

1129040-81D |

4th Cylinder High Pressure Pipe Assy |

1 |

| 35 |

1129050-81D |

5th Cylinder High Pressure Pipe Assy |

1 |

| 36 |

1129060-81D |

6th Cylinder High Pressure Pipe Assy |

1 |

| 37 |

1129070-81D |

High Pressure Pipe Assy I (Pump to Rail) |

1 |

| 38 |

1129080-81D |

High Pressure Pipe Assy II (Pump to Rail) |

1 |

| 39 |

1129090-73D |

High Pressure Pipe Clamp Assy I |

1 |

| 40 |

1129110-81D |

High Pressure Rail Assy |

1 |

| 41 |

Q1840835 |

Hexagon Flange Bolt |

3 |

| 42 |

1104030-18C |

Inlet Pipe Assy – Transfer Pump to Fine Filter |

1 |

| 43 |

1104045-81U |

Transfer Pump Short Pipe Assy |

1 |

Diagnostic Protocols for High-Pressure Safety

Safety is paramount when servicing the FAW Russian Fuel Supply System. The residual pressure in the rail can remain high even after the engine is off. Technicians must crack the Hollow Bolt connections slowly to bleed off pressure before full disassembly. Never use your fingers to check for leaks on a running engine; the high-pressure spray from a pinhole leak in a pipe like the First Cylinder High Pressure Oil Pipe Assembly can penetrate skin.

Visual inspection should focus on the Injector Press Plate area. Wetness here indicates a failed O-ring or spherical washer. Also, inspect the High Pressure Oil Pipe Clamp Assembly. If the rubber dampers in the clamps are worn, the steel pipes will vibrate against the metal bracket, leading to fretting and eventual rupture.

Finally, cleanliness is the greatest maintenance factor for the FAW Russian Fuel Supply System. When replacing the Fuel Fine Filter Assembly, cap all open fuel lines immediately. Even microscopic dust entering the High Pressure Oil Pump Assembly can score the plungers, leading to a loss of rail pressure and a no-start condition in the dead of winter.

Conclusion: The Pinnacle of Diesel Engineering

The FAW Russian Fuel Supply System represents a sophisticated balance of high-pressure hydraulics and robust mechanical engineering. Every component, from the massive High Pressure Oil Rail Assembly to the smallest copper Sealing Washer, plays a crucial role in the engine’s ability to deliver power efficiently and cleanly.

For operators of the CA3250P66K24L1TE5Z, there is no room for compromise. Using aftermarket pipes or reconditioned injectors in the FAW Russian Fuel Supply System is a gamble that often results in engine damage. Only genuine FAW parts provide the metallurgy and dimensional precision required to withstand the 1800 bar pressures and -40°C temperatures of the Russian operating theater.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.