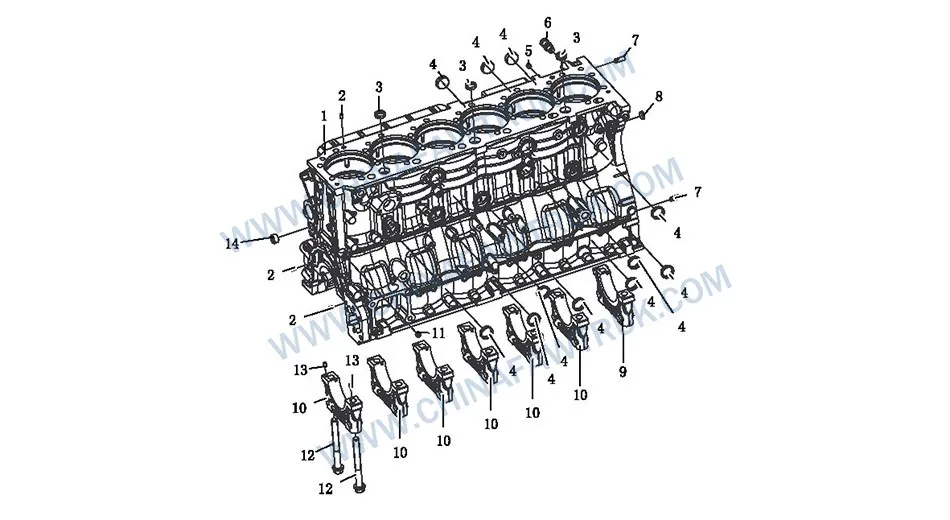

FAW Russian Cylinder Block: Deconstructing 14 Critical Parts for Extreme Cold Reliability

The FAW Russian Cylinder Block is the engineering heart of the CA3250P66K24L1TE5Z dump truck, specifically cast to conquer the freezing temperatures of the Russian Federation. This guide dissects the block’s assembly into 14 maintainable units. Understanding these components is essential for maximizing engine longevity and ensuring reliable operation in the world’s toughest cold zones.

FAW Russian Cylinder Block

The Metallurgy of the Cylinder Block

The primary component, listed as the Cylinder Block (Part No. 1002014-35E), represents the pinnacle of heavy-duty casting technology. For the specific requirements of the CA3250P66K24L1TE5Z model, the FAW Russian Cylinder Block utilizes a proprietary gray cast iron alloy. This material is chosen not just for its strength, but for its thermal damping properties. In the Russian Arctic, an engine can go from -40°C to operating temperature rapidly. Standard iron might crack under this thermal shock, but this specialized block distributes heat evenly to prevent stress fractures.

Structural integrity is further enhanced by the block’s internal ribbing architecture. The design includes reinforced webs connecting the main bearing saddles to the cylinder deck. This rigidity is crucial. As the pistons fire, they exert massive downward force. A weaker block would flex, causing cylinder bore distortion. The FAW Russian Cylinder Block remains dimensionally stable, ensuring that piston rings maintain a tight seal, preserving compression and minimizing oil consumption even after years of service.

Furthermore, the machining precision of the deck surface ensures a perfect seal with the cylinder head. The flatness tolerance of the FAW Russian Cylinder Block is measured in microns. This precision is vital for the head gasket’s performance, preventing coolant from leaking into the cylinders or combustion gases from escaping into the coolant system—a catastrophic failure mode known to plague lesser engines in extreme climates.

Crankshaft Support and Bearing Geometry

The reliability of the rotating assembly hinges on how securely the crankshaft is held. The FAW Russian Cylinder Block employs a robust system comprising six Main Bearing Caps (Part No. 1002011-81D) and one specialized Rear Main Bearing Cap (Part No. 1002012-81D). These caps are not generic; they are manufactured from high-nodular iron to resist fatigue. The rear cap is particularly critical as it houses the rear main seal, the final barrier preventing oil from contaminating the clutch housing.

Securing these caps are fourteen high-strength Main Bearing Bolts (Part No. 1002013A53D-S). In the engineering of the FAW Russian Cylinder Block, these bolts are torque-to-yield fasteners. This means they are tightened until they permanently stretch a specific amount, acting like a very stiff spring. This provides a clamping force that does not loosen under the intense vibration of a diesel engine. Using non-OEM bolts here is dangerous, as they may not have the correct elasticity, leading to cap flutter and spun bearings.

Alignment is the third pillar of this subsystem. The fourteen Cylindrical Pins (Part No. Q5210814) are installed to locate the bearing caps precisely on the block saddle. Without these pins, the caps could shift laterally under load. Such movement in the FAW Russian Cylinder Block would destroy the hydrodynamic oil film protecting the crankshaft. These pins ensure that the center line of the crankshaft remains perfectly true, reducing friction and maximizing power output to the wheels.

Fluid Management in Cold Zones

The “Russian” designation of this FAW Russian Cylinder Block implies a heavy reliance on its freeze protection system. The block is fitted with multiple expansion plugs, specifically the Bowl-shaped Plug (Part No. CQ72240) and larger variants (Part No. Q72232 HB). Often called core plugs, their primary role during casting is to plug sand holes. However, in operation, they serve as a fail-safe. If the coolant freezes and expands, these plugs are designed to pop out, sacrificing themselves to save the engine block from cracking.

Maintenance of these plugs is often overlooked. In the salty, corrosive road environments of Russia, these steel plugs can rust from the outside. A perforated plug leads to rapid coolant loss. We recommend inspecting all Bowl-shaped Plugs on the FAW Russian Cylinder Block annually. If any signs of weeping or rust are visible, they should be replaced immediately. The cost of a plug is negligible compared to the cost of an overheated engine.

Oil containment utilizes a different strategy. The Hexagon Socket Taper Screw Plug (Part No. Q61902 and Q61906) handles the high-pressure oil galleries. Unlike the expansion plugs, these are threaded and tapered. As they are tightened into the FAW Russian Cylinder Block, the threads deform slightly to create a hermetic seal capable of holding back oil pressures exceeding 60 PSI. This ensures that every drop of oil pumped reaches the critical components in the cylinder head rather than leaking externally.

Assembly Geometry and Alignment

An engine is a sum of parts that must be perfectly aligned. The FAW Russian Cylinder Block features a network of dowel pins to guarantee this geometry. The Cylindrical Pin (Part No. Q5211020) and its counterpart (Part No. Q5211232) act as anchors for external components. When mounting the timing gear housing or the flywheel housing, bolts alone are insufficient to resist the rotational torque. These pins take the shear load, preventing the housings from twisting.

This alignment is particularly crucial for the transmission interface. If the bell housing is not perfectly centered on the FAW Russian Cylinder Block, the transmission input shaft will be misaligned with the pilot bearing. This causes vibration, clutch chatter, and premature failure of the input shaft seal. The use of precision-ground FAW pins ensures that the entire powertrain—from engine to gearbox—operates on a single, true axis.

Additionally, the assembly includes the Valve Head – Cylinder Block (Part No. 1002023-81D). While small, this component directs fluid flow within the block’s internal passages. Its precise fitment ensures that there is no cavitation or turbulence in the coolant flow, which could lead to localized hot spots. In the FAW Russian Cylinder Block, maintaining uniform temperature across all cylinders is key to efficiency and emissions compliance.

Component Breakdown List

The following table details the specific components for the FAW Russian Cylinder Block (Model CA3250P66K24L1TE5Z). Please reference these English part names and numbers when ordering spares to ensure compatibility with the cold-zone specification.

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1002014-35E |

Cylinder Block |

1 |

| 2 |

Q5211020 |

Cylindrical Pin |

4 |

| 3 |

Q72232 (HB) |

Bowl-shaped Plug |

3 |

| 4 |

CQ72240 |

Bowl-shaped Plug |

11 |

| 5 |

1002023-81D |

Valve Head – Cylinder Block |

1 |

| 6 |

1002021-53D |

Lifting Bolt |

2 |

| 7 |

Q5211232 |

Cylindrical Pin |

2 |

| 8 |

CQ72224 |

Bowl-shaped Plug |

1 |

| 9 |

1002012-81D |

Rear Main Bearing Cap |

1 |

| 10 |

1002011-81D |

Main Bearing Cap |

6 |

| 11 |

Q61902 |

Hexagon Socket Taper Screw Plug |

1 |

| 12 |

1002013A53D-S |

Main Bearing Bolt |

14 |

| 13 |

Q5210814 |

Cylindrical Pin |

14 |

| 14 |

Q61906 |

Hexagon Socket Taper Screw Plug |

1 |

Proactive Maintenance in Russian Conditions

Operating the FAW Russian Cylinder Block in remote locations requires a proactive mindset. The first step is monitoring the coolant condition. As the expansion plugs (CQ72240) are steel, they are susceptible to electrochemical corrosion if the coolant becomes acidic. A simple pH test performed during oil changes can save the block. We recommend flushing the system annually and using a glycol mixture rated for at least -40°C to prevent internal freezing that could overwhelm the plugs.

When overhauling the engine, the condition of the main bearing threads in the block is paramount. Before installing new Main Bearing Bolts, technicians must clean the threaded holes in the FAW Russian Cylinder Block with a thread chaser. Debris or old thread locker at the bottom of the hole can result in a false torque reading. This means the bolt feels tight, but the cap is actually loose. This error is a leading cause of premature engine failure after a rebuild.

Another critical check involves the Lifting Bolt (Part No. 1002021-53D). These are often left installed on the engine. Over time, vibration can loosen them, or moisture can pool around their base, causing rust. Before attempting to lift a FAW Russian Cylinder Block, inspect these bolts for stress cracks. Using a damaged lifting bolt is a severe safety hazard given the immense weight of the fully dressed cylinder block.

Final Thoughts on Engine Durability

The FAW Russian Cylinder Block is not merely a spare part; it is the structural foundation of your truck’s profitability. Its design reflects a deep understanding of the challenges posed by the Russian climate, from the reinforced casting to the specialized sealing technologies. Every component, from the massive Main Bearing Cap to the smallest Cylindrical Pin, has been engineered to work in unison to resist wear and tear.

By adhering to the maintenance protocols outlined in this guide and using only genuine replacement parts, fleet owners can significantly extend the service life of their vehicles. Do not compromise with inferior aftermarket castings that lack the specific metallurgy of the FAW Russian Cylinder Block. Invest in quality, maintain with precision, and your FAW dump truck will continue to deliver performance in the harshest environments on earth.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.