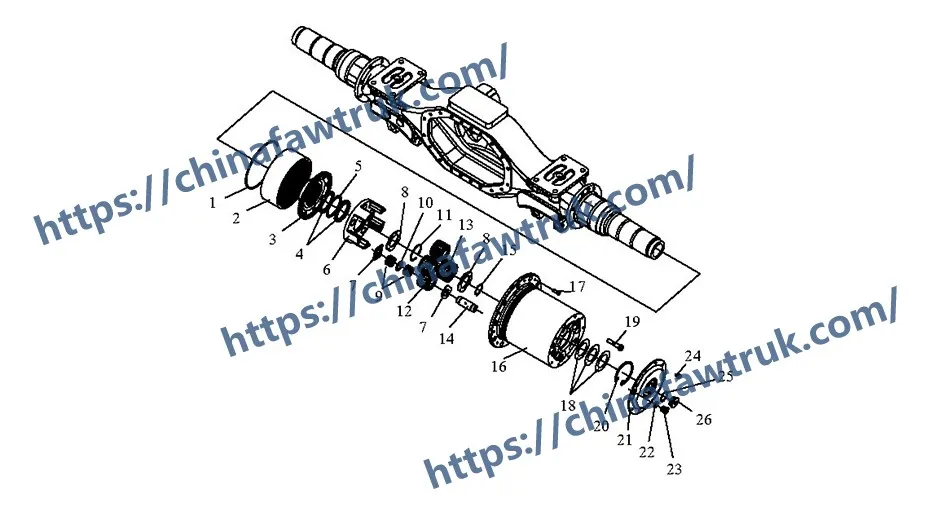

This is a technical breakdown of the FAW J6P Wheel-End Gearbox, a vital component for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide deconstructs the 26 serviceable parts that form this planetary reduction hub, which is the final stage of torque multiplication at the wheel.

The FAW J6P Wheel-End Gearbox is a heavy-duty planetary gearset located inside the wheel hub. Its function is to provide a final, massive gear reduction directly at the drive wheel. This Planetary Reduction Logic multiplies torque one last time, allowing the truck to move extreme loads with less strain on the differential, axle shafts, and driveshaft. This deconstruction will analyze the complete planetary assembly, from the sun gear to the ring gear, to provide a complete service-level overview. A functional FAW J6P Wheel-End Gearbox is essential for the truck’s off-road and heavy-haul capability.

This is the rotating heart of the FAW J6P Wheel-End Gearbox. This assembly takes the input power from the axle shaft (sun gear) and converts it into a high-torque, low-speed output to the wheel hub (planet carrier).

1. Component: ‘Sun gear’ (2405021-A6E) – Qty 4

This (Comp 12) is the ‘Sun gear’. It is the central gear, which is splined directly to the axle shaft. It acts as the “input” for the FAW J6P Wheel-End Gearbox. Its high-speed rotation drives the surrounding planet gears.

2. Component: ‘Planet gear’ (2405031-A6E) – Qty 4 (per unit)

This (Comp 13) is the ‘Planet gear’. The BOM lists 4, which orbit the sun gear. These gears are responsible for the actual gear reduction. They mesh with both the central sun gear (Comp 12) and the outer, stationary ring gear (Comp 2). A faulty planet gear is a catastrophic failure for the FAW J6P Wheel-End Gearbox.

3. Component: ‘Planet carrier’ (2405037-A6E) – Qty 4

This (Comp 6) is the ‘Planet carrier’. This large, heavy-duty component holds the ‘Planet gear axles’ (Comp 14, 2405033-A0E) in place. As the planet gears (Comp 13) “walk” around the ring gear, they force this carrier to rotate. The carrier is bolted to the wheel hub, making it the “output” of the FAW J6P Wheel-End Gearbox. This is what delivers the final, multiplied torque to the tire.

This group forms the stationary foundation of the FAW J6P Wheel-End Gearbox. These components absorb the immense torque reaction from the planetary gearset and must be rigidly secured.

1. Component: ‘Ring gear’ (2405041-A6E) – Qty 4

This (Comp 2) is the large, internal-toothed gear. It is stationary, bolted to the axle housing via its ‘Support’ (Comp 3). The Planetary Logic dictates that the planet gears (Comp 13) push against this gear. The ratio between this ring gear and the sun gear (Comp 12) determines the reduction ratio of the FAW J6P Wheel-End Gearbox.

2. Component: ‘Support – ring gear’ (2405042-A6E) & ‘Snap ring’ (2405043-A6E)

This (Comp 3, 1) is the support bracket that holds the ring gear (Comp 2) in place. It is secured by a ‘Snap ring – ring gear support’ (Comp 1). This support is then bolted to the axle housing itself, ensuring the ring gear cannot rotate.

3. Component: ‘Wheel-end reducer housing’ (2405036-A6E) – Qty 4

This (Comp 16) is the main structural housing. It encloses the entire planetary set, protecting it from contaminants and holding the critical lubricating oil. This housing is a core part of the FAW J6P Wheel-End Gearbox. It is secured by ‘Socket head cap screw’ (Comp 17).

A planetary gearset generates extreme axial (thrust) and radial loads. This group of components is designed to manage these forces and ensure a long service life for the FAW J6P Wheel-End Gearbox.

1. Component: ‘Needle roller’ (9×25.8) & ‘Spacer-needle roller’ (2405034-A0E)

This (Comp 9, 10) is the bearing system *inside* each planet gear (Comp 13). Instead of a solid bushing, this FAW J6P Wheel-End Gearbox uses 1000 ‘Needle rollers’ (per BOM, total for all assemblies) to allow the planet gears to spin freely on their axles (Comp 14) under high load.

2. Component: ‘Thrust washer-planet gear’ (2405032-A0E) – Qty 40

This (Comp 7) is a critical wear item. Forty of these are used (10 per gearbox). A thrust washer is placed on each side of each planet gear. The Thrust Logic is that these washers prevent the steel planet gear from grinding against the steel planet carrier (Comp 6), absorbing the axial forces. Worn thrust washers in a FAW J6P Wheel-End Gearbox will lead to gear misalignment and failure.

3. Component: ‘Thrust washer-sun gear’ (2405022-A6E) – Qty 8

This (Comp 8) performs the same function but for the central ‘Sun gear’ (Comp 12). It absorbs the axial thrust of the sun gear, keeping it perfectly aligned. This is another key part of the FAW J6P Wheel-End Gearbox‘s anti-friction design. ‘Gasket’ (Comp 5, 2405047-A6E) and ‘Elastic stop ring’ (Comp 15, 2405026-A0E) are also used to secure components.

This final group contains the components that seal the unit and allow for routine maintenance of the FAW J6P Wheel-End Gearbox.

1. Component: ‘End cap wheel-end reducer’ (2405061-A0E) & ‘Gasket’ (2405062-DP64)

This (Comp 21, 20.5 – ‘密封垫’) is the outer cover of the hub. This cap (Comp 21) is what is visible on the outside of the wheel. It is sealed with a ‘Gasket’ (Comp 20.5) to keep the gear oil inside. This cap is held on by 40 ‘Bolts’ (Comp 24, 2405063-A0E).

2. Component: ‘Drain plug’ (T60924) & ‘Fill plug’ (T60945)

This (Comp 23, 26) are the service plugs. This Service Logic is essential for maintenance. The ‘Drain plug’ (Comp 23) is at the bottom to drain old oil, and the ‘Fill plug’ (Comp 26) is on the side to add new, heavy-duty gear oil. Regular oil changes are the most important maintenance step for the FAW J6P Wheel-End Gearbox.

3. Component: ‘Adjustment shim’ (2405076~78-A0E) – Qty As Req.

This (Comp 18) is a set of ‘As Required’ shims (t=1.0, 0.5, 0.2). These shims are used during assembly to set the final bearing pre-load or end-play of the entire wheel hub assembly, ensuring no wobble. This precision shimming is the final step in a FAW J6P Wheel-End Gearbox rebuild.

The following table provides the complete, detailed breakdown of all 26 component types in the FAW J6P Wheel-End Gearbox assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for any service of the FAW J6P Wheel-End Gearbox.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2405043-A6E | Snap ring – ring gear support | 4 |

| 2 | 2405041-A6E | Ring gear | 4 |

| 3 | 2405042-A6E | Support – ring gear | 4 |

| 4 | 2405046-A6E | Lock nut – ring gear support | 8 |

| 5 | 2405047-A6E | Gasket | 4 |

| 6 | 2405037-A6E | Planet carrier | 4 |

| 7 | 2405032-A0E | Thrust washer-planet gear | 40 |

| 8 | 2405022-A6E | Thrust washer-sun gear | 8 |

| 9 | 9×25.8 | Needle roller | 1000 |

| 10 | 2405034-A0E | Spacer-needle roller | 20 |

| 11 | 2508054K5H | Steel wire snap ring | 4 |

| 12 | 2405021-A6E | Sun gear | 4 |

| 13 | 2405031-A6E | Planet gear | 20 |

| 14 | 2405033-A0E | Planet gear axle | 20 |

| 15 | 2405026-A0E | Elastic stop ring | 4 |

| 16 | 2405036-A6E | Wheel-end reducer housing | 4 |

| 17 | CQ2181030 | Socket head cap screw | 20 |

| 18 | 2405076-A0E | Adjustment shim (t=1.0) | As Req. |

Packaging and LogisticsFAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability. Other Hot Selling FAW Truck PartsFAW Jiefang TruckOur Hot BlogMore FAW J6 Dump Truck Catalog AnalysisMore FAW J6 Products

Chat with us

|