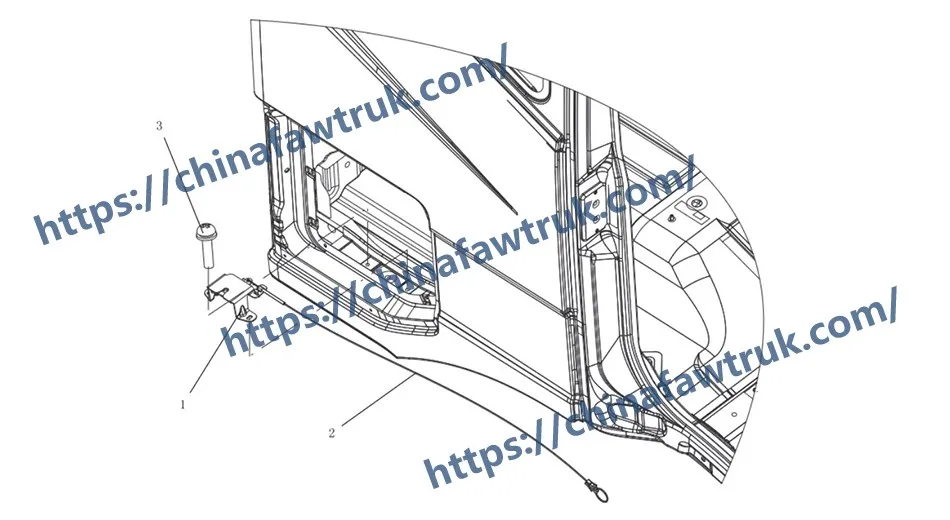

This is a comprehensive technical guide to the FAW J6P Guy Wire assembly (P/N 5402680-A01), a key component of the side panel toolbox lock for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 3 serviceable component types that form this remote latching system.

The FAW J6P Guy Wire, also known as the remote release cable, is a critical component for the functionality and security of the chassis-mounted side toolbox. Its primary function is to translate the pulling force from a key-operated handle (not pictured) to the ‘Lock assy’ (Comp 2), allowing the operator to remotely unlatch the heavy toolbox lid. This is essential for both convenience and security, as it allows the box to be latched from within, protecting the mechanism from external tampering or seizure from mud and ice.

This deconstruction will analyze the key serviceable components of the FAW J6P Guy Wire system. This includes the ‘Cable assy’ itself, the ‘Lock assy’ it actuates, and the specialized hardware used to secure the lock. A failing or seized FAW J6P Guy Wire can render the toolbox inaccessible, trapping critical tools and safety equipment, which can lead to significant vehicle downtime. Maintaining the integrity of the FAW J6P Guy Wire is therefore a key maintenance priority for vehicle readiness.

This component is the core of the FAW J6P Guy Wire system. It is the mechanical link that transmits the release force from the handle to the latch.

1. Component: ‘Cable assy – side toolbox’ (5402680-A01) – Qty 1

This (Comp 1) is the complete FAW J6P Guy Wire. It consists of a multi-strand, high-tensile steel inner wire, housed within a durable, low-friction outer sheath. The Tensile Force Logic is its entire purpose: the inner wire is designed to slide freely within the sheath, transmitting a pull-force from the handle to the lock’s release lever.

The Sheath Protection Logic is critical. The outer sheath, typically made of polymer-lined steel coil, serves several functions. It anchors the cable to the truck body, provides a low-friction conduit for the inner wire, and, most importantly, seals the inner wire from contamination. The FAW J6P Guy Wire is routed in a harsh environment, exposed to water, salt, and mud. A crack or chafe in this sheath is the primary cause of failure, as it allows water to enter and corrode the inner wire, causing it to seize.

2. Failure Modes & Maintenance

The most common failure mode for the FAW J6P Guy Wire is stretching or seizing. Stretching occurs over thousands of actuations, creating “slack” in the system, which results in a “mushy” handle that fails to pull the latch far enough to release. Seizing, caused by internal corrosion, results in a completely stuck handle.

Maintenance of the FAW J6P Guy Wire involves periodic lubrication of the inner wire at its connection points. If the pull action becomes stiff, it is a sign of internal degradation, and the entire ‘Cable assy’ must be replaced. Proper routing, away from high-heat exhaust components and secured with clamps to prevent chafing, is the most important factor in its service life.

This component is the “business end” of the FAW J6P Guy Wire. It is the mechanical latch that physically secures the toolbox lid.

1. Component: ‘Lock assy – side toolbox’ (5402670-A01) – Qty 1

This (Comp 2) is the rotary latch mechanism. The Rotary Latch Logic is a robust design where a striker pin on the lid (not pictured) presses into this latch, forcing an internal cam or “pawl” to rotate and lock behind it. This pawl is spring-loaded, ensuring it cinches the lid down tightly against its weatherproof seal.

The FAW J6P Guy Wire (Comp 1) connects to a small release lever on this assembly. When the cable pulls this lever, it overcomes the spring pressure and retracts the pawl, allowing the lid to open. This mechanism is mounted inside the toolbox, protecting it from direct tampering.

2. Material and Environmental Design

This lock assembly is made from heavy-gauge, zinc-plated, or galvanized steel to resist corrosion. In a dump truck, this component is constantly exposed to a damp, dirty environment inside the toolbox. The internal spring must be high-tensile to provide a reliable, strong latching force over tens of thousands of cycles. A common failure mode is the seizure of the pivot pin for the pawl due to a combination of dirt and rust, which even a perfectly good FAW J6P Guy Wire cannot pull.

This final group includes the hardware used to secure the FAW J6P Guy Wire system components to the toolbox. A secure mounting is essential for proper alignment and function.

1. Component: ‘Cross recessed pan head screw assy’ (Q2360625F6) – Qty 2

This (Comp 3) is the hardware used to mount the ‘Lock assy’ (Comp 2) to the toolbox wall. The Combination Bolt Logic (integrated washer) distributes the clamping load over the thin metal of the toolbox, preventing the screw from pulling through.

The Vibration Resistance Logic is critical. These screws must be installed with a thread-locking compound or must be self-locking. If these screws vibrate loose, the ‘Lock assy’ will shift. This misalignment will cause the striker pin on the lid to miss the latch, and the FAW J6P Guy Wire system will fail to lock, potentially allowing the toolbox to fly open during operation.

2. Installation and Alignment

When replacing either the FAW J6P Guy Wire or the ‘Lock assy’, alignment is key. The lock must be mounted so that it securely captures the lid’s striker, pulling the lid down firmly onto its seal. Once the lock is secure, the cable (Comp 1) is connected and adjusted. There is typically an adjustment point (a threaded barrel or clamp) where the inner wire connects to the latch or the handle, allowing the technician to remove all slack. This adjustment is the final step in servicing the FAW J6P Guy Wire assembly.

The following table provides the complete, detailed breakdown of all 3 component types in the FAW J6P Guy Wire (Side Panel Toolbox Lock) assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for any service of the FAW J6P Guy Wire system.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5402680-A01 | Cable assy – side toolbox | 1 |

| 2 | 5402670-A01 | Lock assy – side toolbox | 1 |

| 3 | Q2360625F6 | Cross recessed pan head screw assy | 2 |

The specifications for the FAW J6P Guy Wire are defined by its function as a remote, cable-driven latching system for the chassis-mounted toolbox.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Guy Wire (Toolbox Latch System) |

| Primary Logic | Remote mechanical latching and security |

| Actuation Method | ‘Cable assy’ (5402680-A01) |

| Latching Component | ‘Lock assy’ (5402670-A01) |

| Mounting Hardware | ‘Cross recessed pan head screw assy’ (Q2360625F6) |

| Total Component Types | 3 |

| Associated System | Side Panel Toolbox. The FAW J6P Guy Wire provides the release mechanism. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.