Welcome to this definitive technical analysis of the FAW J6P Flywheel (P/N 1005121-630-0000). This is the “Rotational Battery” for the engine in the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

This component is not just a heavy disc; it is a “Logic Assembly” engineered to store and smooth out the engine’s power.

The “logic” of the FAW J6P Flywheel is to convert the violent, intermittent “punches” of combustion into the smooth, continuous torque needed to move the truck. It is also the primary interface for the vehicle’s clutch.

The “Dual Logic” of this FAW J6P Flywheel is its most important feature. First is its “Inertia Logic.” A 6-cylinder diesel engine fires in violent, individual power strokes. The massive weight of the FAW J6P Flywheel absorbs this kinetic energy and uses inertia to keep the crankshaft spinning smoothly between these power pulses. Without this, the engine’s vibration would be uncontrollable. Second is its “Clutch Logic.” The flywheel is machined with a perfectly flat, heat-resistant “friction surface.” The clutch disc presses against this surface, and this is the exact point where 100% of the engine’s power is transferred to the transmission. A warped or cracked FAW J6P Flywheel will destroy a clutch and make the truck undrivable.

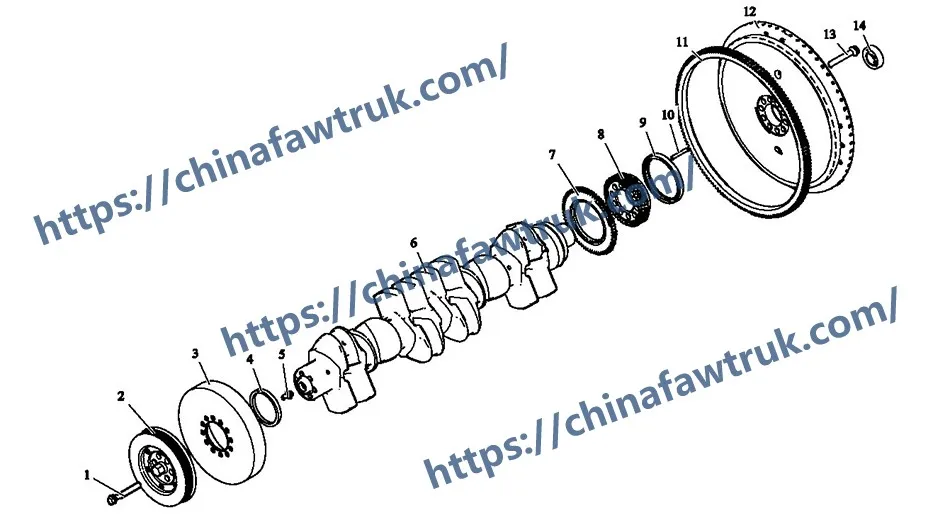

This expert guide is an essential resource for transmission specialists, engine rebuilders, and fleet parts managers. We will deconstruct the entire component group associated with the FAW J6P Flywheel. We will analyze the “Inertia & Clutch Logic” (the flywheel itself), the “Alignment & Interface Logic” (the positioning key and pilot bearing), the “Critical Fastener Logic” (the high-tensile TTY bolts), and the “Associated Sealing Logic” (the rear main seal).

This component is the main event. Its logic is to store energy and provide a friction surface for the clutch.

1. Component: ‘Flywheel’ (1005121-630-0000)

This (Comp 12) is the main FAW J6P Flywheel. Its “Inertia Logic” comes from its massive weight, typically made from nodular cast iron. This weight acts as a “rotational battery,” storing the kinetic energy from each combustion “punch” and releasing it smoothly, which is what provides the engine with stable idle and smooth torque delivery. Without this mass, the engine would shake violently and stall.

The “Clutch Logic” is its secondary function. The flat, wide, machined face is the primary “friction surface” for the clutch disc. This surface must be perfectly flat (with a tolerance of thousandths of an inch) and durable enough to withstand the intense heat and friction from clutch engagement, especially in a heavy-duty dump truck application. The third “logic” of the FAW J6P Flywheel is its “Starter Logic.” The hardened “ring gear” on its outer edge is what the starter motor engages to turn the engine over. A missing or damaged tooth on this ring gear will prevent the engine from starting.

This group of small components has a critical “logic” of ensuring perfect, micron-level alignment between the engine and the transmission.

1. Component: ‘Positioning key – …flywheel’ (1005031-29D)

This (Comp 10) is the “Rotational Alignment Logic.” A FAW J6P Flywheel is externally balanced *with* the crankshaft. It *must* be installed in the one, and only one, correct orientation. This small steel “key” fits into a groove on the crankshaft flange and a matching slot in the FAW J6P Flywheel, making it impossible to install incorrectly. This logic is essential for a vibration-free engine.

2. Component: ‘Ball bearing 60305-2RS’ (GB/T 276-1994)

This (Comp 14) is the “Transmission Interface Logic,” commonly known as the “pilot bearing.” This small, sealed bearing is pressed into a recess in the very center of the FAW J6P Flywheel (or the end of the crank). The “nose” of the transmission’s input shaft rides inside it. Its “logic” is to support the transmission shaft and keep it perfectly centered with the crankshaft’s centerline. A failed pilot bearing is a common cause of clutch failure, “grinding” noises when the clutch is pressed, and difficulty shifting gears.

This component’s logic is to provide the massive, unwavering clamping force required to hold the FAW J6P Flywheel to the crankshaft against all rotational forces.

1. Component: ‘Flywheel bolt’ (1005071K29D)

The list calls for ten (10) of these critical bolts (Comp 13). These are not standard hardware. Their “logic” is “Critical Clamping Force.” They are engineered to handle the immense “sheer” force of transferring the engine’s full torque, as well as the “tensile” force of the clutch clamping.

These are almost universally “Torque-to-Yield” (TTY) bolts. The “TTY Logic” is that they are designed to be torqued to a specific point where they *permanently stretch*. This stretching action turns the bolt into a high-tension spring, providing a perfectly consistent clamping force that will not loosen under vibration. This is why they are *single-use*. Once stretched, they are compromised and MUST be replaced every time the FAW J6P Flywheel is serviced. Re-using them is a critical error that can lead to the flywheel detaching from the engine—a catastrophic, transmission-destroying failure.

This final group consists of the serviceable components that are part of the “master” crankshaft group but are directly related to the FAW J6P Flywheel installation.

1. Component: ‘Rear oil seal’ (1005060-29D)

This (Comp 9) is the “Main Seal Logic.” It is a large-diameter, high-temperature rubber seal that is pressed into the engine block or a seal housing *before* the FAW J6P Flywheel is installed. The flywheel’s mounting flange (or a sleeve) spins inside this seal. Its “dynamic sealing” logic allows the crankshaft to spin freely while preventing oil from leaking out of the “rear main” of the engine. A failure here is a very common and major oil leak that will contaminate the clutch, causing it to slip and fail.

2. Component: ‘Thrust ring’ (1005122-29D)

This (Comp 11) is the “Clutch Interface Logic.” This ring is likely a “shim” or “thrust ring” that works with the clutch assembly, not the FAW J6P Flywheel itself. Its “logic” is to ensure the clutch pressure plate is properly spaced and aligned when bolted to the flywheel, guaranteeing the correct clamp load and a clean release.

The following table provides the detailed breakdown of the 6 component types directly associated with the FAW J6P Flywheel assembly, based on the master crankshaft group for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 9 | 1005060-29D | Rear oil seal | 1 |

| 10 | 1005031-29D | Positioning key – main drive gear & flywheel | 1 |

| 11 | 1005122-29D | Thrust ring | 1 |

| 12 | 1005121-630-0000 | Flywheel | 1 |

| 13 | 1005071K29D | Flywheel bolt | 10 |

| 14 | GB/T 276-1994 60305-2RS | Ball bearing 60305-2RS | 1 |

The specifications for the FAW J6P Flywheel are defined by its function as the power-transfer and inertia-storage component of the engine.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Flywheel & Power Transfer Assembly |

| Main Flywheel P/N | 1005121-630-0000 |

| Primary Logic | Rotational Inertia (Smooths Power), Clutch Interface (Transfers Power) |

| Secondary Logic | Starter Motor Engagement (Ring Gear) |

| Critical Fasteners | ‘Flywheel bolt’ (1005071K29D) – Qty 10 |

| Fastener Type | Torque-to-Yield (TTY) – Single-Use, Must Be Replaced |

| Alignment System | ‘Positioning key’ (1005031-29D) |

| Transmission Interface | ‘Ball bearing 60305-2RS’ (Pilot Bearing) | Two (2)

| Associated Sealing | ‘Rear oil seal’ (1005060-29D) |

| Associated System | Part of the master FAW J6P Crankshaft assembly |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.